Editor's Note: When we commissioned this article from Bob Gosch (better known as "Bob the Driveshaft Guy" in NASCAR shops), we had no idea how complicated this seemingly simple part was. It is critical that the part match the application in many different ways. Here he explains why in Part One of a two-part analysis that every racer should heed.

The driveshaft of the modern racing stock car is one of the most critical links in transferring the power of the engine through the drivetrain to the track. If your driveshaft fails, you have failed. Because it is usually one of the last parts assembled to the car, racers in a hurry tend to forget that great care should be taken when specifying a new shaft.

During the racing season, the driveshaft system should receive regular inspection and its components should be replaced on a firm schedule to ensure reliability. A driveshaft failure on the track will inevitably result in a wrecked race car and possible injury to yourself, your fellow racers, and your wallet.

1. DRIVESHAFT

Operating Environment The racing driveshaft operates in a confined space with no cooling provisions while surrounded by the hottest components of the race car. Inches from the track, the driveshaft is fully exposed to debris from other cars, chunks of rubber, and red-hot sparks of metal from dragging chassis parts. The driveshaft is always rotating whenever the car is moving and spends most of its life at the highest rpm the engine can sustain.

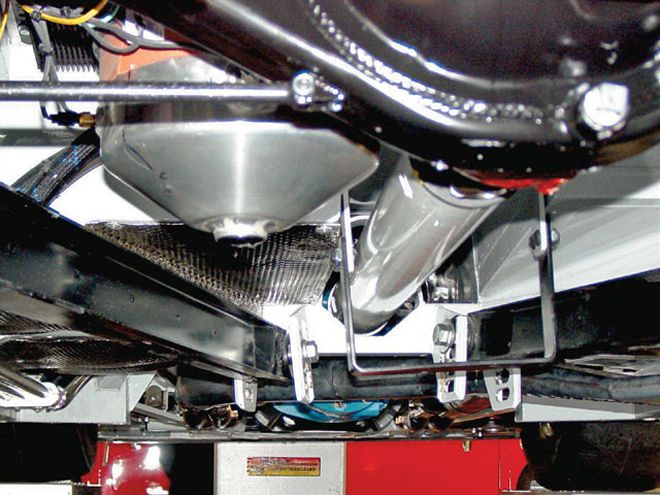

We need to pay attention to the clearances of the driveshaft to other components under the car. Setting the car at ride-height configuration and moving the rear end to midturn position can help us align the driveshaft and to make sure there is no interference with other parts of the car.

We need to pay attention to the clearances of the driveshaft to other components under the car. Setting the car at ride-height configuration and moving the rear end to midturn position can help us align the driveshaft and to make sure there is no interference with other parts of the car.

2. TUNNEL CLEARANCE

When a race car chassis is built, the fabricator creates a tunnel in the floorpan to accommodate the driveshaft. Based on his experience, he allows enough volume in the tunnel for the shaft to operate. But he normally does not know what major components will eventually be used in which combination.

Older chassis are often converted to different brands, and transmissions are routinely changed. Assuming that the driveshaft will always have sufficient clearance to operate properly is wishful thinking-it must always be checked.

The more complicated the type of car, the more equipment exists that can interfere with the driveshaft. In a properly designed driveshaft, all of the parts needed for your type of racing fit together with no conflicts. This means all of the components can be removed for servicing without disrupting the other parts.

The more complicated the type of car, the more equipment exists that can interfere with the driveshaft. In a properly designed driveshaft, all of the parts needed for your type of racing fit together with no conflicts. This means all of the components can be removed for servicing without disrupting the other parts.

3. OBSTRUCTIONS

When you are constructing a new race car, always mock-up the location of the major components first and inspect the tunnel area for interferences or obstructions to the driveshaft zone. The underside of the tunnel should be as smooth as possible with no protruding fasteners.

NASCAR's Car of Tomorrow incorporates a full tunnel design to surround the driveshaft. This piece is composed of heavy 0.125-inch-thick steel with reinforced ends of a much heavier solid steel part. This will virtually eliminate damage to the car and injury to the driver should the driveshaft break.

NASCAR's Car of Tomorrow incorporates a full tunnel design to surround the driveshaft. This piece is composed of heavy 0.125-inch-thick steel with reinforced ends of a much heavier solid steel part. This will virtually eliminate damage to the car and injury to the driver should the driveshaft break.

4. OPERATING CLEARANCES

There must be adequate clearances for the driveshaft to follow the movement of the rear axle. Travel the rear axle assembly through its range of motion and check for any resulting obstruction to the shaft. Now is the best time to correct any potential problems by repositioning smaller components or re-contouring floor protrusions.

It is a common practice to run hard lines for engine oil transfer along the underside of the driveshaft tunnel. These lines not only introduce extra heat into the tunnel, but also become a serious limitation to driveshaft size and a potential disaster if the driveshaft fails and tears them open. Likewise, a large oil tank snuggled up next to the driveshaft for weight distribution reasons is a needless risk.

This rear hoop has a neat design and can be easily removed for servicing the driveshaft. It is made of thick steel strap and bolted with two bolts on each side to the chassis.

This rear hoop has a neat design and can be easily removed for servicing the driveshaft. It is made of thick steel strap and bolted with two bolts on each side to the chassis.

5. DRIVESHAFT LOOP DESIGN

All sanctioning bodies require some form of driveshaft safety loop to prevent a flailing, broken driveshaft from injuring the driver or leaving the car. But few car builders give much thought to the magnitude of the potential damage. This is not the place to skimp on material or do the minimum allowed. The driveshaft loop should be substantial enough in thickness and mounting to contain the wild gyrations of the broken shaft and protect the adjoining flooring and oil tank. While driveshaft failures are rare, they can be catastrophic even if the car doesn't crash as a result.

6. DRIVESHAFT LOOP PLACEMENT

The driveshaft loop must be placed in a location that allows it to effectively restrain the shaft and be replaced on a regular basis. A two-piece bolt-together design can make driveshaft removal much easier. The loop is typically placed about two thirds of the length of the shaft from the front U-joint and must be large enough to allow a smooth insertion of the shaft into the transmission while the rear axle is at full drop. A little thought expended here during the mock-up phase can save a lot of frustration on Saturday afternoon.

7. DRIVESHAFT ALIGNMENT

The mock-up phase of car assembly is a good time to begin checking driveshaft alignment. Position the engine to meet all of its location constraints for best weight distribution and ensure the rear axle location meets wheelbase requirements.

Using a tool like the True Laser Track System, you can make sure that the rear axle and the transmission output shaft are aligned in two planes and that the resulting U-joint angles will be as close to zero as possible at running ride height. Any significant offsets in alignment should be corrected at this time. The new True Laser Track Driveline Alignment tool is very helpful in determining how to reposition the major components to bring them into alignment.

8. DRIVESHAFT SPECIFICATION

Your test day is now scheduled and your new car is finally coming together. Your new engine is sitting on the floor, that new transmission you first saw at PRI is now here, and your gear shop has brought over the correct rear ratio. If your mock-up process went well, it should all bolt together on that shiny new frame. But many variables and adjustments can affect the final choices you need to make before ordering that critical last link in the drivetrain-the driveshaft.

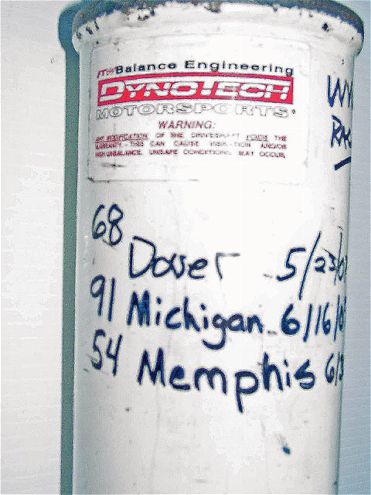

You should get in the habit of marking your driveshaft as to the amount of usage and the racetracks where it ran. Here we see where the team clearly marked the track, the date the D/S was run, and the number of laps.

You should get in the habit of marking your driveshaft as to the amount of usage and the racetracks where it ran. Here we see where the team clearly marked the track, the date the D/S was run, and the number of laps.

9. RACING SERIES RULES

First, you must research the appropriate rules for your racing series as they apply to the driveshaft. For example, in most cases, NASCAR will specify a required material ("magnetic steel"), a minimum diameter ("no less than 4.0 inches"), a minimum thickness ("no less than 0.065 inch"), and a required paint color ("painted white"). These specifications have been implemented for safety reasons and are based on industry recommendations for critical speed capability and durability for your series. But there still are several choices to be made before you can order the right shaft.

10. MATERIAL SELCTION

If your rules are not specific about material, you can choose from a bewildering menu of steel, chrome-moly steel, aluminum, MMC aluminum, or carbon-fiber composites. Low-cost short-track shafts are typically steel or aluminum. High shock load applications such as those found in road racing and drag racing will demand chrome-moly steel or MMC aluminum shafts for durability. The lightest and most expensive choice for professional road racing and dirt track racing is the carbon-fiber composite shaft.

This view shows the different sizes of driveshaft that are available, from 3.0- to 4.5-inch diameters. The diameter that you will need for your car is dependent on the power your engine puts out and the maximum rpm the D/S will experience. Other factors include the length of the D/S as well as weight considerations.

This view shows the different sizes of driveshaft that are available, from 3.0- to 4.5-inch diameters. The diameter that you will need for your car is dependent on the power your engine puts out and the maximum rpm the D/S will experience. Other factors include the length of the D/S as well as weight considerations.

11. MINMUM DIAMETER

A racing driveshaft can be made in a variety of tubing diameters, from typically 2.5 to 4.5 inches. The correct choice for your application is best determined by understanding the concept of critical speed. Critical speed is an engineering calculation based on the tube's thickness, material, and length. This calculation determines the rpm at which a given shaft enters its critical speed zone.

At this speed, the shaft is likely to experience lateral bending that will make it try to leave the vehicle. Sustained operation at or above this critical speed means certain and rapid failure of the shaft will occur. It is important that a racing driveshaft be specified to ensure that its critical speed is above the normal operating rpm range of the vehicle.

For example, a Late Model two-barrel car operating below 7,000 rpm can safely use a 3.0-inch shaft, but a Hooters Pro Cup Late Model operating near 8,500 rpm cannot. If in doubt, your driveshaft distributor and/or manufacturer can recommend the best combination to avoid any critical speed issues.

12. DIAMETER SELECTION BY SELECTION

In most cases, a series' rules will dictate the desirable diameter. For the NASCAR Sprint Cup COT, Busch car, Craftsman truck, and ARCA car, the driveshaft is required to be 4.0 inches. The USAR Hooters Pro Cup Series cars and the NASCAR Busch East and West Series cars typically use a 3.5-inch shaft with 1350 U-joints for critical speed reasons. Low-horsepower short-track Late Models should use such robust shafts as well, but most still use the weaker 3.0-inch driveshaft and 1310 U-joint combination.

13. MINIMUM THICKNESS

For NASCAR and short-track steel driveshafts, there are also several choices for tubing thickness. The lightest and most expensive thickness is 0.065 inch. This helps reduce rotating mass to help the race car accelerate faster out of the corner. For durability and cost reasons, some teams specify a thickness of 0.083 inch. These shafts are somewhat heavier but give crew chiefs added peace of mind when tackling the rigors of concrete short tracks.

For heavy-duty applications, such as drag racing and off-road trucks, shafts with even thicker walls may be preferable. Once again, consult your driveshaft distributor and/or manufacturer to get the best recommendations for your needs.

14. COLOR

NASCAR and other race sanctions require a driveshaft to be painted white. The reason for this goes back to the days of true stock car racing, when driveshaft failures were more common. If a car lost a driveshaft on the track, the drivers following often could not see the dark and heavy shaft lying on the black asphalt and would run it over, turning it into a deadly missile or crashing themselves.

A white driveshaft is very visible and can be easily avoided. Of course, today, driveshafts leaving a car are very rare and an errant lightweight driveshaft would probably crumple like an empty soda can. But this requirement still exists as a safety feature.

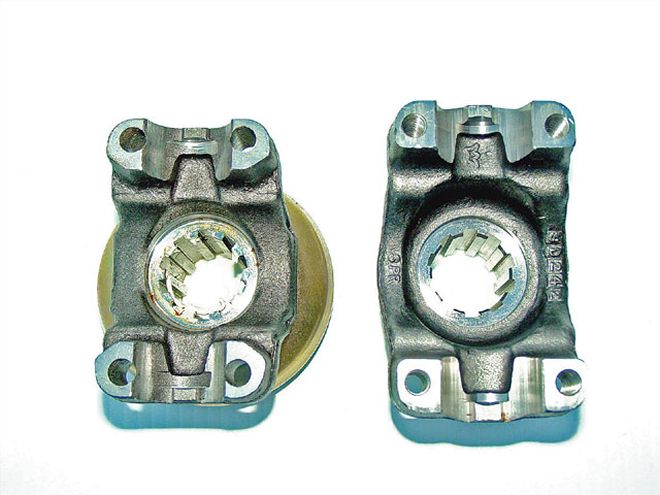

The U-joints shown are the 1350 (left) and the 1310. The 1350 has a 45 percent larger bearing cup and a thicker cross area to handle higher-horsepower applications.

The U-joints shown are the 1350 (left) and the 1310. The 1350 has a 45 percent larger bearing cup and a thicker cross area to handle higher-horsepower applications.

15. U-JOINT SERIES IDENTIFICATION

Two of the most critical choices to be made are size and construction of the U-joints. It is necessary to specify a racing-quality U-joint of sufficient strength to survive a full season of hard use. Street cars and low-horsepower Late Models typically use a 1310 series U-joint.

Heavier trucks and stock cars with high horsepower use the larger 1350 series part. The 1350 U-joint has 45 percent larger bearing cups and a thicker cross to better handle the load. A racing-quality U-joint does not have a grease fitting and does not need periodic greasing. The hole for the grease fitting in a U-joint weakens the strength of the cross and becomes the immediate failure point for a highly stressed joint.

16. OUTPUT SHAFT BEARING IDENTIFICATION

Most stock car racing aftermarket transmissions use the tried-and-true GM 32-spline output shaft design to interface with the driveshaft. Even though this allows the slip-yoke specification to be standardized, there are still choices to be made.

The transmission manufacturer can install a simple bronze bushing as the wear surface or, as an option, have the housing machined for use of a double-roller bearing setup to reduce internal friction. It's important that you know which design you have to make the correct slip-yoke choice. Ask your transmission supplier which system he uses or visually inspect behind the tailshaft seal for a bushing or bearings.

This cast or forged yoke was used with a tailshaft with a roller bearing. Note the obvious wear right where the bearings contacted the yoke. It should have only been used with a bushing-style tailshaft. For roller bearing applications, use a hardened billet steel yoke (such as the ones from Mark Williams or C&R Racing).

This cast or forged yoke was used with a tailshaft with a roller bearing. Note the obvious wear right where the bearings contacted the yoke. It should have only been used with a bushing-style tailshaft. For roller bearing applications, use a hardened billet steel yoke (such as the ones from Mark Williams or C&R Racing).

17. SLIP-YOKE SELECTION

The conventional non-hardened cast or forged slip-yoke is well suited for use with a bushing in the transmission tailhousing. But it will quickly fail when used with a roller bearing. The roller bearing setup utilizes the barrel of the slip-yoke as the inner race of the assembly, and the barrel must be hardened to match the rollers or they will rapidly wear a groove into the barrel.

18. BILLET SLIP-YOKES

High-quality hardened billet steel slip-yokes from Mark Williams Enterprises or C&R Racing are the best choice when using a tailshaft roller bearing. These precision parts come at a higher price but will typically outlive a given shaft. NASCAR teams routinely harvest billet yokes from older shafts to build them into fresh ones.

19. SLIP-YOKE SPLINES

There are varying opinions on the need for venting the slip-yoke for smooth travel. Some manufacturers machine one or two of the splines to act as a channel for trapped air to escape as the slip-yoke moves in and out.

The original production reason for the missing spline was to speed up car assembly by allowing the stock driveshaft to be quickly shoved into place. The racing driveshaft, on the other hand, will travel very little in normal use, and venting is not a big problem as air can find its way past the array of splines.

These two types of rearend yokes are the 1310 (left) and 1350 quick-change yokes. Whichever yoke you choose, make sure that the other end of the driveshaft has the matching yoke. Don't use a 1310 quick-change yoke with a 1350 tranny slip-yoke.

These two types of rearend yokes are the 1310 (left) and 1350 quick-change yokes. Whichever yoke you choose, make sure that the other end of the driveshaft has the matching yoke. Don't use a 1310 quick-change yoke with a 1350 tranny slip-yoke.

20. REAREND YOKE SELECTION

It is important that your driveshaft U-joint series choice be matched by the specification of the pinion yoke on your rear gear. Any mismatch between the front and the rear of the shaft means that the smaller U-joint becomes a potential fuse, which will inevitably break first.

We have more information coming next month about racing driveshafts. Make sure you choose the correct driveshaft for your particular application. If in doubt, contact your supplier, ask a lot of questions, and provide the needed information. Your success and race car's reliability depend on it.

"I NEED A DRIVESHAFT TO TEST MY CAR TOMORROW."

Your new engine has just arrived and you realize that you need a new driveshaft now! Bob Gosch, of Rapid Response in Mooresville, North Carolina, is a driveshaft specialist. He has worked for 30 years within all kinds of motorsports. He has been the operations manager for numerous racing-related companies and technical director of the International Motor Sports Association.

Bob's company supplies many NASCAR and other series' teams with specialized racing driveshafts. He can normally deliver a new racing driveshaft from Rapid's extensive inventory to a team very quickly. Many NASCAR teams count on Rapid Response as their inventory partner to deliver shafts for their specific requirements on a "just-in-time" basis.

"We typically ask three simple questions to fit the correct shaft, but the customer has to be ready with the answers to get it right," Bob says.

1."What series do you race in?" This determines the material, diameter, thickness, and U-joints needed.

2. "Does your transmission have roller bearings in the tailshaft housing?" The roller bearings require a hardened billet slip-yoke.

3. "What is your length?" Racing driveshafts are specified by the length from the center of the front U-joint to the center of the rear in 11/44-inch steps.

Armed with these answers, Rapid Response can get you going. As Bob says, "You can get a custom Dynotech driveshaft in Mooresville faster than you can get a pizza!"