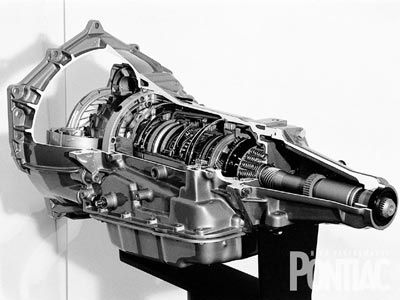

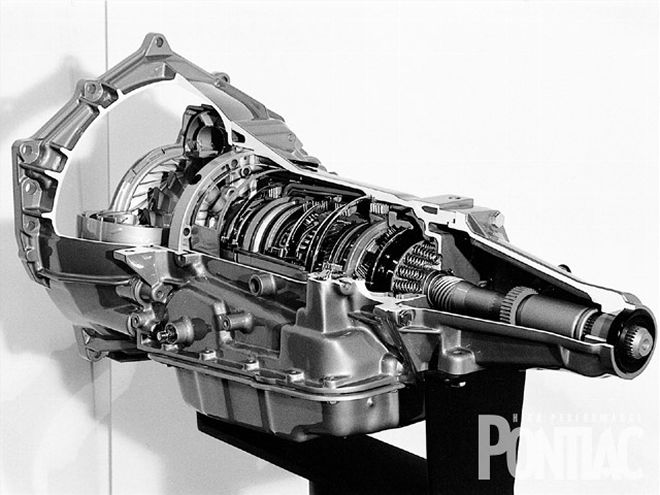

Standard equipment in the F-car and a slew of other V-8-powered GM vehicles, the Hydramatic 4L60-E four-speed automatic transmission is a capable performer-to a point.

With a maximum engine torque capacity of 360 ft-lb, the "L60," as GM engineers call it, is best suited to moderate performance applications. Recently a new, stronger version of the L60 has quietly appeared. It's the 4L65-E and it has been attached to 6.0L versions of the Gen. III V-8 found in half-ton trucks, like the Cadillac Escalade AWD. In these vehicles, the "L65" has an engine torque rating of 380 ft-lb.

In the last year or so, an automotive application of the L65 was tuned for the high-performance HSV vehicles of GM's Australian Holden unit. These are rear-drive, LS1-powered cars, including the Holden Monaro coupe, which is being morphed into the '04 Pontiac GTO.

Besides the higher torque rating, the L65 is simply built tougher than the L60. In fact, in automotive applications, the L65's torque rating is closer to 400 ft-lb. "The L65 is stronger all around," says Steve Ford, GM's assistant chief engineer for the 4L60 and 4L80. "Although it was initially built for truck applications, the gearing we've developed for automotive duty cycles makes it a great performance upgrade. Right out of the box, it can handle about 20 percent more torque than the L60."

GM Performance Parts has released the 4L65-E as an over-the-counter item (PN 24221888), hoping to lure enthusiasts with older vehicles to the benefits of the electronically controlled overdrive transmission, as well as offering modern performance enthusiasts a stronger alternative to the stock 4L60-E. In a nutshell, the L65 differs from the 4L60-E in these ways:

* Five-pinion gears for input and reaction gearsets (versus four-pinion gears in the L60)* Heat-treated stator shaft splines* Induction hardened turbine shaft* Heavier-duty Low/Reverse roller clutch* Additional friction plate added to 3-4 clutch(seven plates versus six in L60)* Shot-peened output shaft* Revised valvebody calibration.

The 4L65-E's inner strength comes from this collection of upgraded components, as compared with the lighter-duty 4L60-E transmission. Hardened stator, turbine and output shafts are included, as is a five-pinion reaction carrier and 3-4 clutch pack with an additional friction plate.

The 4L65-E's inner strength comes from this collection of upgraded components, as compared with the lighter-duty 4L60-E transmission. Hardened stator, turbine and output shafts are included, as is a five-pinion reaction carrier and 3-4 clutch pack with an additional friction plate.

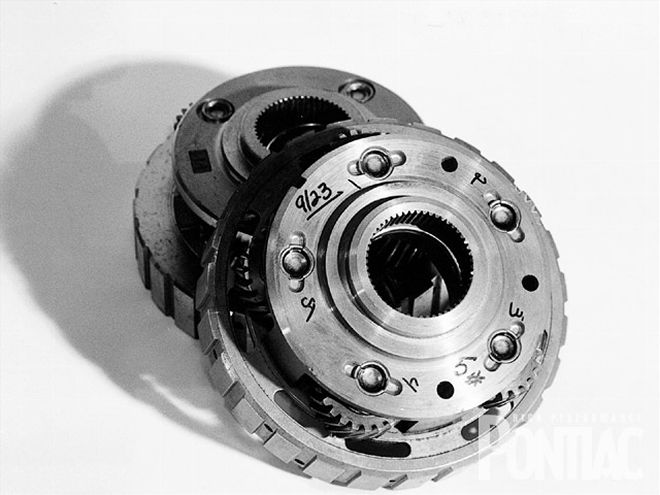

The use of five pinion gears for the input and reaction gearsets spreads the torque load so that less is held by any one gear. L65's gears also are made of powdered metal, which GM claims allows for more precise detail and accuracy of the part, as well as higher overall strength. (In these GM transmissions, the input and reaction gearsets are comprised of a sun gear, planetary gears and a ring gear.)

Additionally, a heavy-duty, needle-type thrust bearing replaces a thrust washer for the interface between the reaction shaft and the reaction sun gear and shell.

Increasing the strength of the stator shaft came from heat treating the shaft's splines (which mesh with the hub of the stator roller clutch), and substituting the L60's steel-backed bronze bushings with stronger aluminum versions.

Also in the L65, the turbine shaft (the main component transferring torque from the converter into the transmission) is strengthened through induction hardening. Compared to heat treating, which involves a heating/cooling cycle to improve hardness and strength, induction hardening utilizes an electric current in the heating/cooling cycles.

The L65's five-pinion reaction carrier is shown here on top of the L60's four-pinion carrier. Adding the additional planetary gear to the carrier reduces the overall torque load that each gear has to carry, thereby improving the carrier's overall strength and lifespan.

The L65's five-pinion reaction carrier is shown here on top of the L60's four-pinion carrier. Adding the additional planetary gear to the carrier reduces the overall torque load that each gear has to carry, thereby improving the carrier's overall strength and lifespan.

"The premium parts specified for the L65 are similar to parts you'd find in aftermarket performance build-ups," says Ford. "They were included for durability and the transmission's performance design."

Another improvement specific to the L65 is the use of larger-diameter rollers in the roller clutch. They better handle the increased loads of the L65, as do the seven friction plates of the 3-4 clutch. The L60 has only six friction plates for the 3-4 clutch; adding a seventh plate creates higher shift energy capacity.

Hydramatic engineers also improved the output shaft's capacity through shot-peening. The process involves concentrating the peening in several high-stress areas of the output shaft, thereby producing a longer fatigue life.

Like the reaction carrier, the L65's input carrier assembly is upgraded from four to five gears (right). With the 4L60-E's four-pinion input carrier shown to the left of the L65's carrier for comparison, it's easier to see how the five-pinion design spreads out the load among the planetary gears.

Like the reaction carrier, the L65's input carrier assembly is upgraded from four to five gears (right). With the 4L60-E's four-pinion input carrier shown to the left of the L65's carrier for comparison, it's easier to see how the five-pinion design spreads out the load among the planetary gears.

Despite these upgrades, the L65's gearing remains the same as the L60's: 3.059 for first gear, 1.625 for second, 1.000 for third, and .0696 for the overdrive.

Finally, the L65's valve body, including line pressure and shift timing, differs from the L60 by optimizing shifts based on a higher engine torque curve. Also, to withstand the higher fluid pressure of the L65, the springs in the accumulator valve are stronger than those in the L60.

Shift points for the L65 are programmed to complement the LS6 engine and, compared with the 4L60-E, the maximum shift speeds for each gear change is lowered from 6,100 rpm to 5,600 rpm

"Although the 4L65-E was originally developed for trucks, the transmission available through GM Performance is specifically tailored to cars," says Ford. "We think it offers the best compromise to a five-speed manual. It's got great strength and the gear ratios complement a car's power-to-weight ratio."

But, Will it Fit?All the improvements made to the 4L60-E to make the 4L65-E are internal, so it will bolt up to any vehicle originally equipped with the 4L60-E. And since the L60/L65 transmissions are basically electronically controlled versions of the 4L60 (which was known as the 700-R4 until the early '90s), they'll bolt up to most GM vehicles from the early '80s and up.

Of course, the 4L65-E requires the use of an electronic controller, whereas the non-electronic versions of the L60 or 700-R4 do not. These non-electronic overdrive transmissions, however, were used in computerized applications and adapting them to carbureted, non-computer vehicles requires the use of a throttle valvespring and some "just right" adjustments to ensure proper kickdowns.

Another comparison, this one depicts the L60 (left) and the L65's input sun gears. The L65's gear is made of powdered metal, the production of which, GM says, ensures a more accurately cast part.

Another comparison, this one depicts the L60 (left) and the L65's input sun gears. The L65's gear is made of powdered metal, the production of which, GM says, ensures a more accurately cast part.

That's not the case with electronically controlled transmissions like the L65. Swapping it into an older vehicle, though, requires the use of its electronic controller. And if the swap is performed with a carbureted vehicle, an aftermarket controller kit with a specialized throttle position sensor is a must. Aftermarket vendors, such as JET Performance (www.jetchip.com) or Phoenix Transmission Products (www.phoenixtrans.com) offer such kits.

You'll also want to look to Phoenix Transmission if you want to bolt up the L65 to your old Pontiac engine. They have a B-O-P kit that includes an adapter plate and converter pilot extension. TCI Automotive has a B-O-P adapter plate, too, (PN 230001).

Here are a few additional transmission swap considerations:* The two-piece case of the 4L65-E is bulkier than, say, a Turbo 350 or Turbo 400, which means the transmission tunnel may need massaging.* The L65 is relatively long (approximately three inches longer than a TH350), therefore a custom driveshaft may be required.* Depending on the vehicle, a new rear crossmember may be required to mount the tail end of the transmission.* Because the L65 uses an electronic signal toindicate vehicle speed, a mechanical speedometer won't work without a signal converter, such as Abbott Enterprises' Cable X (see sidebar story).

GM supplies the torque converter with the transmission but not the electronic controller (it uses the L60 controller, PN 12497316). Also, most shift linkages from older GM vehicles can be made to work with it. In fact, Shift Works (www.shiftworks.com) offers conversion kits to adapt stock-type shifters of vintage Firebirds, GTOs and LeMans, including Super Turbine 300 (two-speed auto) applications, to modern GM transmissions. Year One offers similar products.

Truth be told, a prepped 700-R4, a non-electronic 4L60, or even a 200-4R along with GM's throttle valvespring kit (PN 24502513), is a less expensive option than the electronically controlled L65 for a vintage, non-computer controlled car. However, if you're looking for a stronger trans for your Third- or Fourth-Gen Firebird, the L65 is an easy swap. It's also great if, say, you plan to put an LS1-based drivetrain in your old Tempest.

The five planetary gears of the input carrier are turned by the input sun gear. As noted in previous photo captions, the five-pinion design reduces the load on each of the gears, thereby strengthening the entire unit and allowing for increased torque capacity.

The five planetary gears of the input carrier are turned by the input sun gear. As noted in previous photo captions, the five-pinion design reduces the load on each of the gears, thereby strengthening the entire unit and allowing for increased torque capacity.

There are, of course, other choices when it comes to GM overdrive transmissions, notably the 4L80-E and 4L85-E. Found primarily in heavy-duty trucks, the L80 and L85 certainly offer robust torque capacity ratings (440 ft-lb and 460 ft-lb, respectively). But, they are designed for truck applications-specific gear spacing and a 2.48 first gear. "The L80 and L85 are better suited to big-block applications," says Jim La Fontaine, lead systems engineer for transmissions at GM's Performance Division. "The L65 is suited to small-block engines; it's designed to fit with the drivetrain of a small-block-powered vehicle to make installation relatively simple."The L65 has another important advantage over the L80: it's lighter. A 4L65-E weighs about 55 pounds less than an L80 or L85.

When ordered through a GM dealership, the 4L65-E has a list price of $2,595, not including the necessary controller (we're told an inclusive kit is in the works). However, most dealers will be able to sell the L65 for about $2,200 or less.

Yes, you could probably upgrade an existing L60 for less, but we think the thoroughness of 4L65-E's revisions make it an attractive alternative. It also offers the benefits of being brand new and warranted. Heck, if it's strong enough for the 5,800-pound Escalde AWD, it ought to handle your late-model Firebird or possibly your vintage LeMans.

Cable X: Abbott Enterprises' quick fix for using an electronic transmission with a mechanical speedoDespite the performance and economy advantages of using an electronically-controlled automatic transmission in your vintage ride, there's a potential hiccup: the transmission's electronic speed signal has no provision for a mechanical speedometer.

Abbott Enterprises, of Pine Bluff, Arkansas, has a solution. Its Cable X converter transforms the electronic signal of the transmission into a motor-driven output that drives a traditional mechanical speedometer.

The L65's turbine shaft (top), which is driven by the converter's turbine as fluid from the impeller is splashed on it, is induction-hardened. The L65's output shaft (bottom) is strengthened over the 4L60-E's shaft with selective shot peening.

The L65's turbine shaft (top), which is driven by the converter's turbine as fluid from the impeller is splashed on it, is induction-hardened. The L65's output shaft (bottom) is strengthened over the 4L60-E's shaft with selective shot peening.

In a nutshell, the $300 Cable X is a box with electronic connections on one side and a mechanical cable hook-up on the opposite side. A motor inside the box turns the speedometer cable based on the signals received by the electronic transmission.

"It's an easy install," says Abbott's John Ware. "There are just three wires for the transmission and simply the cable hook-up for the speedometer."

Ensuring the speedometer's accuracy falls to adjustable dip switch settings on the Cable X box, which calculate the correct number of pulses per mile based on the transmission gear (number of teeth), axle ratio and tire size. Abbott Enterprises says the device is accurate to 2 percent of the transmission's electronic signal.

"The dip switch programs the correct speed formula," says Ware. "Overall, it's a simple procedure."

Simple also describes the idea to bring the Cable X to the enthusiast market. Previously, Abbott Enterprises' existence depended solely on the trucking industry. The company manufactures a variety of tachographs and other speed/timing equipment for the over-the-road crowd. But the growth of GPS navigation and tracking cut into Abbott's core business.

"We had a couple of car enthusiasts at the company who suggested the Cable X would be great for older cars using modern transmissions," says Ware. "Frankly, we didn't think there would be much of a market for that application, but the phones haven't quit ringing. The response has been terrific."

The stator is the reaction (stationary) member of the torque converter for torque multiplication. It controls fluid flow from the impeller in the reduction phase of the converter's operation. To handle its increased torque capacity, the 4L65-E's stator shaft splines are heat-treated to increase their strength.

The stator is the reaction (stationary) member of the torque converter for torque multiplication. It controls fluid flow from the impeller in the reduction phase of the converter's operation. To handle its increased torque capacity, the 4L65-E's stator shaft splines are heat-treated to increase their strength.

Clearly, great ideas are where you find them-even if it's just a twist on an old one. -BK

A Brief History of the GM Modern OD TransmissionsIntroduced in 1982, the 700-R4 was one of General Motors' first production automatic overdrive transmissions. It shared the limelight with the B-O-P-specific 200-4R, which was found in countless G-bodies, Cadillacs, and other larger GM vehicles. (Thanks to a "universal" bolt pattern, it found its way into some Chevys, too.)

Although it looks like a terrific wedding band for a gear head, this delicate looking piece of "jewelry" is the Low/Reverse roller clutch. It looks identical to the L60's but GM says it's a heavier-duty component designed for the L65's higher torque capacity.

Although it looks like a terrific wedding band for a gear head, this delicate looking piece of "jewelry" is the Low/Reverse roller clutch. It looks identical to the L60's but GM says it's a heavier-duty component designed for the L65's higher torque capacity.

Two versions of the 700-R4 appeared: one with a 60-degree, bellhousing bolt pattern and another with a 90-degree bolt pattern. And though the advantages of lower cruising rpm and higher fuel economy were widely praised, the early 700-R4s suffered from weaknesses that caused many to fail in even the lightest-duty applications.

By the '87 model year, the 700-R4 had been internally upgraded and the demons that caused many a burned-up transmission had been exorcised. In the '90s, the name changed to 4L60, reflecting GM's new nomenclature for all its transmissions - "4" for four-speed, "L" for longitudinal (rear-wheel drive), "60" denoting the torque capacity rating. (The "E" was added when the transmission was converted to electronic control.)

But while the name of the transmission changed (probably to make wary consumers forget about past 700-R4 problems), the design was the same. The 700-R4 and 4L60 are internally similar, including gearing.

The 4L60-E came along in the mid-'90s, and shortly thereafter its design was changed from a three-piece construction to a two-piece design. Currently, the L60 and L65 have a separate, 360-degree bellhousing, which completely encloses the torque converter. This was done to increase powertrain stiffness and reduce vibration.

For stronger 3-4 shifts, the 4L65-E's 3-4 clutch pack has seven friction plates. The 4L60-E's 3-4 pack has just six plates.

For stronger 3-4 shifts, the 4L65-E's 3-4 clutch pack has seven friction plates. The 4L60-E's 3-4 pack has just six plates.

Electronic versions of the transmission also use an electronically-controlled capacity clutch, instead of a mechanical lock-up clutch. This design lets the computer decide on the necessary amount of slip, which maximizes fuel economy.

As for the 4L80-E and L85, they are descended from an even older GM transmission, the Turbo 400. Essentially, the L80 and L85 are Turbo 400s with an overdrive gear and electronic controller. Of course, the Turbo 400 is merely a heavy-duty, slightly longer version of the venerable Turbo 350.

The names may have changed, but the transmission cases didn't. -BK