| The Ultimate Mitsubishi Lancer Evo Suspension - Garage Tech

| The Ultimate Mitsubishi Lancer Evo Suspension - Garage Tech

We have covered suspension buildups on the EVO VIII and IX before, but this time we decided to try something special. We decided to build the ultimate no-holds-barred suspension for the EVO, money not being an object, the only caveat being that it had to remain streetable and not be so stiff that it needed a rollcage to function properly. We're attempting to build the ultimate setup for time attack in the Limited or Street Modified classes.

When attempting a bold endeavor it's best to consult with those who've been there before. Fortunately for us, the EVO is such a popular and flexible platform that there are many companies who specialize in getting them to stick like glue to the pavement. We called upon Robert Fuller (or Robi for short) for some much-needed advice. At the track, Robi has always been a big help, instantly springing through the garage door, tools in hand whenever a loud crash or a burst of foul language was heard. Despite being a fierce competitor Robi has always been there to help out from simple advice to all-out wrenching at the track, even when we were out to beat him.

| The Ultimate Mitsubishi Lancer Evo Suspension - Garage Tech

| The Ultimate Mitsubishi Lancer Evo Suspension - Garage Tech

This spirit has always earned our respect and we always wanted to pick his mind directly on a project but we've never had one that matched his specialty, making EVOs and Subarus corner like Velcro on Velcro through his suspension tuning company, Robispec. That all changed when South Coast Mitsubishi made us an offer on a brand new EVO IX that we couldn't refuse and we found ourselves taking one home. Within days we found ourselves calling Robi and finally initiating that project. Robi was an instrumental adviser for all aspects of our build. Although we mostly sourced our own parts for this build, Robispec stocks and recommends nearly all of the parts we used.

With deadlines depressingly close and an injured back aching, we had to enroll the help of some competent professionals to slap our EVO's suspension together. As we have many times in the past, we called upon Howard and Ritchie Watanabe of Technosquare to help us with our install in record time. Technosquare is a race prep shop located in Torrance, Calif., and the Watanabe brothers have many years of experience in getting SCCA, NASA road race, pro rally and drift cars working fast. Technosquare really is the best damn garage in town and the bros are capable of lightning-fast, high-quality work.

| Moton Motorsports 3-way adjustable dampers, Eibach ERS main and tender springs, GC camber/caster plates and Works pillow ball mounts are a combination that is tough to beat.

| Moton Motorsports 3-way adjustable dampers, Eibach ERS main and tender springs, GC camber/caster plates and Works pillow ball mounts are a combination that is tough to beat.

The basis of any suspension buildup revolves around the dampers or shock absorbers. Good dampers can make or break a cars' handling and are often overlooked or maladjusted by the inexperienced. For our dampers we got our inspiration not from the streets of Tokyo, or any street for that matter, but from the paddock at SCCA Speedworld Challenge and Grand Am Cup races. While walking pit row at these events, we noticed that many of the top cars had one thing in common, Moton dampers. Moton is a Dutch company but they have a North American operation that supports their products. Moton has very technically advanced dampers and we opted for their 3-way adjustable Motorsports units, cost being no object.

Are dampers that cost nearly a quarter of the price of the car worth it? No, if you're just interested in high-performance street driving. Moton makes a much lower cost Clubsport damper for you. If you're actually going to the track and competing then these highly adjustable dampers might make the difference between winning and losing. The Motorsport dampers are 3-way adjustable independently for high- and low-speed compression damping and rebound damping. High-speed compression affects how the car will react when hitting big abrupt bumps. You can adjust the high-speed damping to keep the car from crashing through the travel and bottoming out hard when you hit an FIA curb while still providing a compliant ride.

| The front Moton strut housings use these plates with a hose of various offsets to locate the upper bolt where it connects to the spindle to roughly adjust negative camber and steering axis inclination angles.

| The front Moton strut housings use these plates with a hose of various offsets to locate the upper bolt where it connects to the spindle to roughly adjust negative camber and steering axis inclination angles.

The low-speed damping circuit mostly affects body roll and pitch, as does the rebound control. With the ability to adjust low and high speed and rebound damping independently, it's possible to have a car that can meet all of these seemingly diametrically opposite goals, taking on big hits, resisting roll, squat and dive and riding relatively smooth. Contrary to popular belief, race cars need to ride as smoothly as is practical to reduce tire shock. Tire shock is any sort of hopping or skipping that upsets the tires contact patch. For a tire to give its best grip, it has to be planted solidly on the ground. A car that bobs, rolls excessively or hops is losing grip. With the sophisticated damping control that Moton offers, it's possible to get away with a softer spring for less tire shock and a decent street ride to boot. Conversely, a high spring rate for the street can still ride well due to the Moton dampers precise control.

Moton dampers have a high-precision valve system so that each click of the adjusters changes the damping force by an equal amount. Hardly any shocks can do this and common street adjustable coilovers aren't even close to having consistent changes for each click. Most shocks adjust damping force by changing the preload on a stack of valve washers. Moton dampers change the diameter of precisely machined metering orifices when you turn the knob. The dampers also have a large diameter shaft, which displaces a lot of fluid as the shaft is pushed into the shock body. More shaft displacement means more fluid flow though the valves. The large volume of fluid makes the shocks valving all the more sensitive, even at low shaft speeds.

| Here is where the plate attaches to the strut.

| Here is where the plate attaches to the strut.

Moton dampers also have adjustable gas pressure. There's a shraider valve in the shocks remote reservoir where the nitrogen gas pressure can be adjusted. The nitrogen is kept separate from the fluid in the remote by a floating piston. Gas pressure works like spring preload. It changes the force needed to move the suspension initially but doesn't affect the spring rate. It's possible to raise the gas pressure for a more responsive suspension for the track and to reduce it for a softer street ride. The Moton strut bodies also have an adjustment for camber built into the lower mounts. This enables us to adjust both the caster and the steering axis inclination angle.

To attach the Moton dampers to the front of our car's chassis we used a Ground Control camber caster plate. We think the GC unit is superior to any currently on the market for several reasons. The first is that it allows a generous amount of caster adjustment. We feel that the EVO needs more positive caster. Positive caster improves straight-line stability and the EVO has such telepathic steering that it can be twitchy when driving on the freeway. Adding caster can improve this. Positive caster also increases negative camber when the wheel is turned, which helps front grip, making the addition of positive caster a win-win situation. The GC plates bolt on top of the strut tower so they allow the car to be set lower while maintaining wheel travel. Insufficient wheel travel is a common handling problem with radically lowered cars. Finally, the GC plates incorporate an ingenious system to reduce the load on the spherical bearing the shock shaft rides on. The upper spring seat has a ball and socket surface with a roller thrust bearing underneath it. The ball and socket allows the suspension to articulate smoothly through its travel and as the wheels are turned while the thrust bearing supports the weight of the car. This allows the GC plate to last a long time without maintenance.

| Whiteline's steering precision kit reduces bushing flex and bumpsteer by relocating the steering rack slightly and replacing soft rubber bushings with polyurethane.

| Whiteline's steering precision kit reduces bushing flex and bumpsteer by relocating the steering rack slightly and replacing soft rubber bushings with polyurethane.

For the rear suspension we used Works rear pillow ball mounts. The Works mounts do away with the factory stock squishy rubber mounts, replacing the rubber with a spherical bearing held in an anodized billet aluminum housing that bolts to the body. The bearing allows the suspension to articulate smoothly while assuring that every bit of movement is controlled by the damper. Low speed control takes place at under 2 inches per second velocity and the stock rubber mounts can stretch and allow up to 1 inch of vertical shock shaft movement. With superior dampers that work well at these low velocities, it's easy to understand why solid high-quality mounts are important.

| Whiteline's roll center kit helps raise the roll center on lowered cars, reduce bumpsteer and improves the camber curve for more front bite.

| Whiteline's roll center kit helps raise the roll center on lowered cars, reduce bumpsteer and improves the camber curve for more front bite.

Of course we cannot overlook the springs. After consulting with Robi on spring rates we chose 2.2-inch Eibach ERS racing springs. Eibach ERS springs are available in a tremendous array of lengths and weights, which makes a suspension tuners life much easier. We settled on 7-inch long 550 in/lb front and a 650 in/lb rear springs with a 200 in/lb tender spring. These spring rates are nearly three times stiffer than stock but are still considered on the soft side for track use. The tender springs are bottomed out with the cars weight on them but they come into play by helping keep the car's inside wheels on the ground in real hard cornering. This helps forward traction on the exit of turns. Although a stiffer spring rate is often used on the track, a chassis without a cage cannot easily make use of rates much higher than this. If the springs are too stiff then the cageless chassis flexes and becomes a giant undampened spring, which can contribute to tire shock. Robi's philosophy is to use soft compliant springs to allow the suspension to work and to limit roll by using stiff anti-sway bars and by raising the front suspensions roll center.

| You can see how much taller the Whiteline roll center ball joint is compared to the stock part.

| You can see how much taller the Whiteline roll center ball joint is compared to the stock part.

When it came to anti-sway bars we naturally used Robispec adjustable units. The Robispec bars are 25mm up from the stock 24mm for the front bar with two adjustment holes and 26mm up from the stock 22mm for the rear bar with four adjustment positions. The front bar can be up to 80 percent stiffer than stock, depending on which hole it's adjusted to, and the rear bar up to 140 percent stiffer, depending on which hole is used. The Robispec bars come with urethane mounting bushings and the rear bars come with a heavy-duty chassis bracket that better withstands the stress of the thicker bar. The bars also have adjustable end links featuring spherical bearings rather than the stock plastic ball and socket joints. It is important to get rid of bar preload after corner weighting.

When setting up a car at the track, unless you have a big pit crew, performing a spring change to change the balance of the car in the time allotted between run groups is nearly impossible. However, it's pretty easy to adjust the sway bars to change the cars balance. Setting the car up stiffer in the rear and softer in the front increases oversteer or decreases understeer. Stiffening the front bar and softening the rear decreases oversteer or increases understeer.

| Look at how much longer the shank is on the Whitleine ball joint compared to stock.

| Look at how much longer the shank is on the Whitleine ball joint compared to stock.

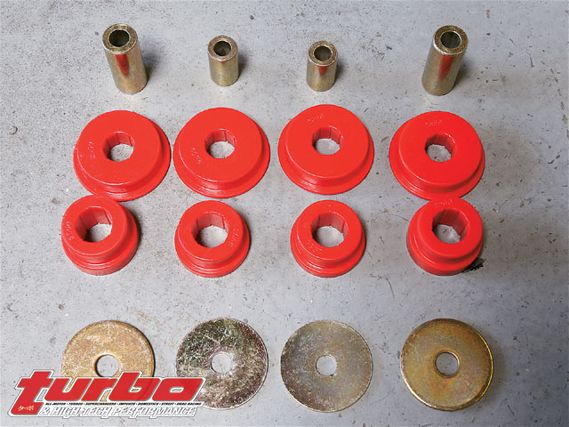

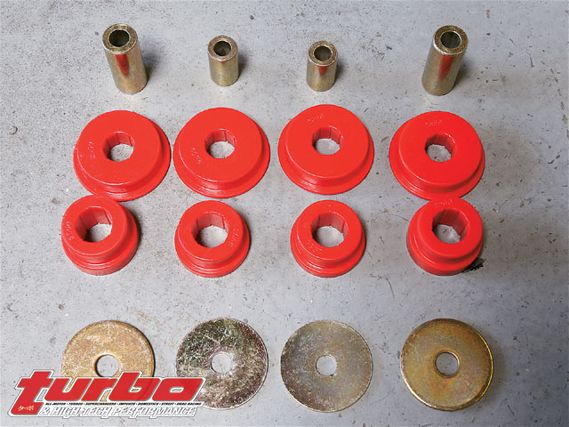

Robi made sure we addressed other details necessary in building the ultimate EVO suspension. We replaced the front lower control arm bushings with harder Energy Suspension polyurethane bushings. The rear lower control arm bushing is a high-quality rubber mounted spherical bearing and following Robi's advice we left it stock, however Energy does make a hard urethane replacement for this part with a special tapered center bore to allow it to articulate.

We used Whiteline's steering precision kit to mount our EVO's steering rack. The kit replaces the rubber bushings holding the steering rack with hard urethane and moves the rack up slightly to reduce bumpsteer. The kit is designed to impart a more solid steering feel and improve the secure feeling of the steering when transversing bumpy surfaces.

| Energy urethane trailing arm bushings take much of the gush out of the rear suspension.

| Energy urethane trailing arm bushings take much of the gush out of the rear suspension.

Whiteline's roll center adjustment kit was also installed in the front suspension. This unique and innovative product makes an EVO handle well. We're used to hand fabricating this sort of part on our racing cars, but Whiteline simplified it by making it a bolt on product for the EVO. The roll center adjustment kit uses a ball joint with a longer shank. This effectively moves the lower control arm outer pivot downward and raises the roll center. In a lowered car, the roll center drops and the roll couple, which is the lever arm for centrifugal force to roll the car over, gets longer. Thus a lowered car often exhibits more body roll than a car at stock ride height all other things being equal. The Whiteline kit is designed to move the roll center close to the stock location even on a lowered car.

| Whitelines's bumpsteer kit relocates the rear toe arm inner pivot upward, which reduces bumpsteer in the rear suspension.

| Whitelines's bumpsteer kit relocates the rear toe arm inner pivot upward, which reduces bumpsteer in the rear suspension.

On a McPherson strut car, if the car is lowered so that the lower control arms are at an angle of more than 90 degrees to the strut itself, the suspension will gain positive camber under roll. This is terrible for grip and handling. The Whiteline kit helps reduce this effect, further improving handling. Unfortunately, changing the location of the pivot in relation to the tie rod ends can create a lot of bumpsteer. Whiteline cleverly included tie rod ends with longer shanks in the kit to keep the tie rod location in line with the new lower control arm pivots. Now you can do this former race car-only mod for a surprisingly low price. What used to require over a $1,000 of specialized parts and custom fabrication to accomplish is now a relatively inexpensive bolt on. If all of this sounds confusing, quite simply, the roll center adjustment kit will reduce body roll and improve front grip without increasing the spring or sway bar rates.

For the rear suspension, we kept most of the EVO's stock control arm bushings because they are high-quality bearings rather than the soft rubber found on most stock cars. We replaced the soft rear trailing arm bushing with a hard Energy polyurethane piece. We also used Whiteline's rear bumpsteer elimination kit. This kit uses an eccentric bushing to replace the inner pivot bushing of the rear toe arm. The eccentric is used to locate the pivot location downward. This reduces bumpsteer in a lowered car. Reducing bumpsteer gives the rear of the car a more secure feel at the limit, especially over uneven pavement.

| You can see how the inner pivot is higher than the stock when the bushing is installed in the car.

| You can see how the inner pivot is higher than the stock when the bushing is installed in the car.

Power modded EVOs tend to develop wheelhop when launching from a dead stop or when accelerating out of a tight turn. Much of the wheelhop is caused by bushing deflection in the drivetrain. We installed Energy Suspensions urethane bushings in the rear moustache bar and front differential mount. These soft rubber bushings mount the rear differential to the chassis and replacing them with harder urethane reduces the likelihood of developing wheelhop and breakage of the axles, transfer case and rear differential. We noticed a very slight increase in gear noise from the differential but this was to be expected.

| Energy replaces the rear mustache bar and differential bushings with hard urethane to help reduce wheel hop.

| Energy replaces the rear mustache bar and differential bushings with hard urethane to help reduce wheel hop.

Finally, we added Whiteline's front and rear adjustable sway bar endlinks. These parts use solid spherical bearings to couple the sway bar to the suspension control arms. This assures that every bit of suspension movement is coupled to the anti-sway bar. This helps sharpen response in a very feelable way. Now the EVO uses a plastic ball and socket endlink stock, which is better than your typical rubber-mounted endlinks. However, the beefy Whiteline parts can better take the stress of the big Robispec bars. Another important feature is that the Whiteline endlinks can be adjusted for length. This allows the user to adjust the length of the endlinks when the wheels are on the ground after the car has been cornerweighted to take the bind out of the sway bar. This assures consistent handling from right to left. As a final nice touch, the Whiteline bits have rubber dust shields to help the spherical last longer in the sometimes hostile street environment.

| Whitelines sway bar end links are very strong and stuffed with bearings instead of bushings for a razor-sharp response. They are also adjustable to eliminate sway bar preload.

| Whitelines sway bar end links are very strong and stuffed with bearings instead of bushings for a razor-sharp response. They are also adjustable to eliminate sway bar preload.

Since we're running race car spring rates we had to significantly beef up our chassis stiffness in order for our suspension to work properly. Usually a race suspension won't work well on typical street cars because its stiff springing will allow bumps to flex the body instead of the suspension, allowing the body to become a huge undampened spring, which can contribute to oscillations and tire shock. A flexing chassis also leads to a harsh ride. This is one reason why a rollcage is usually critical in a race car's suspension system. A stiff chassis rides smoother, offers sharper response to control inputs and responds better to chassis tuning. Fortunately for us (so we don't ruin our street car), a roll cage isn't allowed in the Street or Limited Time Attack classes so we weren't tempted to tear up our brand new interior and weld some bars in. Fortunately the EVO's WRC rally-bred chassis is much stiffer than many cars from the factory. Also, a lot of excellent chassis braces are available for the EVO on the market.

| We used a hydraulic press to remove and install the suspension bushings. Since the EVO's forged aluminum suspension links are weakened by heat, a torch can't be used to burn out the stock bushings, which is a common method for normal steel arms on other cars.

| We used a hydraulic press to remove and install the suspension bushings. Since the EVO's forged aluminum suspension links are weakened by heat, a torch can't be used to burn out the stock bushings, which is a common method for normal steel arms on other cars.

We chose what we feel are some of the best braces on the market to significantly stiffen our EVO's chassis, enough so that we can get away with race car-like spring and damping rates on the street. For the all-important strut tower brace, we chose the sturdy brace offered by Works. The Works front strut tower brace is a lighter, super-stiff version of the factory piece. This bar incorporates all the OEM mounting locations and increases the torsional rigidity of the chassis by reducing body flex in the front end. The Works brace is made out of billet aluminum with a brushed anodized finish and rust resistant coated hardware. What's cool is that the solid billet construction made it easy for us to make brackets to mount the remote reservoirs of our Moton dampers directly to the brace. The Works front brace has a unique feature, the ability to adjust the brace's mounting position on the firewall vertically. This worked out really well for us because our GC camber plates bolt to the top of the strut tower which makes the strut tower brace sit about 31/48 of an inch higher. This would mean that you would have to tweak the braces to get the bolts to line up with the firewall mounting point, not a big deal but a fiddling step for sure. Since the Works brace's firewall mounting point is adjustable for height, we were able to accommodate the additional height of the camber plate without tweaking anything. Later we found out that the Works engineer who designed the brace also designed the GC camber plate. No wonder they work so well together!

| The Works billet aluminum front brace triangulates the front end for maximum stiffness. It works well with our GC camber plates and is a good place to mount the remote reservoirs of our Moton struts.

| The Works billet aluminum front brace triangulates the front end for maximum stiffness. It works well with our GC camber plates and is a good place to mount the remote reservoirs of our Moton struts.

Of course we could not ignore the rear of the chassis. To beef up the stiffness of the rear we used another Works product, the Works rear tower brace/cage. Made of strong anodized aluminum billet like the front brace, the Works rear strut tower brace ties the rear shock towers together. To improve chassis rigidity even more we added the optional Works Drop Bars. These billet bars bolt to the strut tower brace and go rearward where it ties into the optional factory RS brace. When combined with the rear truck brace from the EVO RS, the entire assembly forms an integrated completely boxed in multipoint cage for the ultimate in bracing. We mounted our Moton reservoirs to the drop bars so the low- and high-speed compression damping adjusters would be easily accessed. We also cut a hole in the trunk liner over the shock towers so we could easily reach the rebound adjusters and quickly make damping changes at the track.

| We used Adel clamps bolted to the Works brace with stainless button-head Allen bolts for a sans remote mount. Note the easy access to the adjusters and the nitrogen fill valve. This is important for fast adjustment in the pits.

| We used Adel clamps bolted to the Works brace with stainless button-head Allen bolts for a sans remote mount. Note the easy access to the adjusters and the nitrogen fill valve. This is important for fast adjustment in the pits.

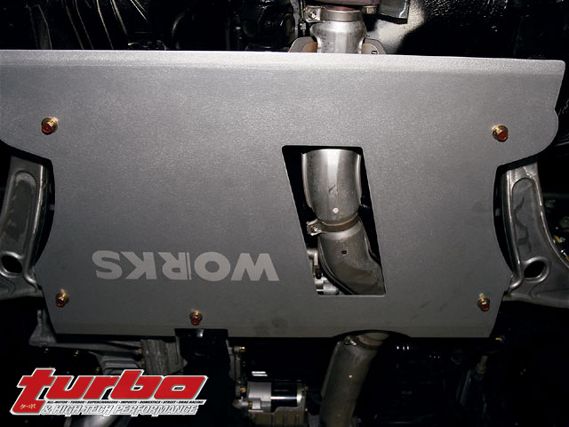

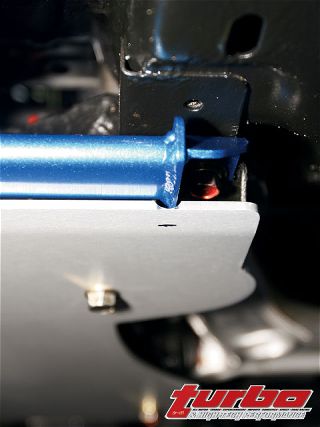

We also paid a lot of attention to bracing up the cars midsection. The factory underchassis braces are two small wimpy tubes. We replaced them with Works Croxx Plate II. The Croxx Plate II is constructed of 4.5mm (31/416 of an inch) 6061 aluminum and then Type II clear anodized. It replaces the two factory front crossbars by combining them into one solid structural member to stiffen the chassis and prevent unwanted suspension deflection. Since all five mounting points of both bars are secured to one single plane, the Croxx Plate II sharpens the steering, helps keep the wheel alignment true underload, makes the car feel more solid and, for those of you out there taking your EVOs to extremes, it acts as a skid plate to prevent damage to undercarriage components from stones, road debris and the occasional hard landing after becoming airborne. For those who stick to tarmac use like us, the Croxx Plate II's other advantage is that it cleans up some of the underbody aerodynamics.

| The Works rear cage significantly stiffens the whole back of the car with four points of boxing in. The lower rear RS brace can't be seen in the picture but it ties into the bars that go from the rear shock towers to the back of the car. This is also a cool place to mount our Moton remotes.

| The Works rear cage significantly stiffens the whole back of the car with four points of boxing in. The lower rear RS brace can't be seen in the picture but it ties into the bars that go from the rear shock towers to the back of the car. This is also a cool place to mount our Moton remotes.

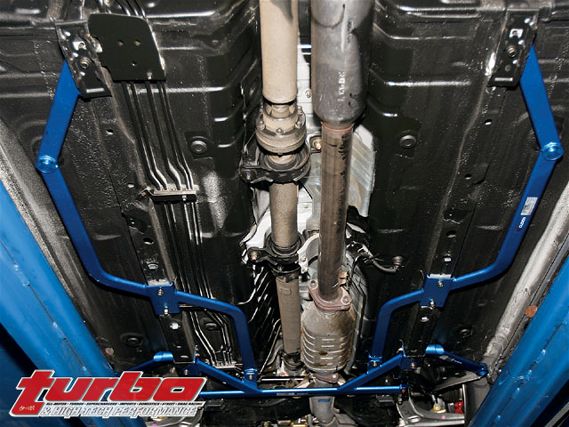

To really stiffen the chassis without resorting to a rollcage, we also used Cusco's new underchassis power braces. The power braces tie the chassis together completely, from our Croxx brace all the way to the back of the car. They bolt in at multiple points and form a stiff ladder frame that greatly reinforces the factory unibody. The braces are made of rectangular section steel tubing with hydroformed curves to maintain strength in this difficult-to-bend material. Hydroforming is a process of filling a tube with a fluid filled bladder for bending. This is the best way to bend a tube because it distributes the stress evenly about the tube and reduces the creation of weak zones. It is about the only way to bend a rectangular tube on its major axis without wrinkling it. The braces come in three parts: a front center brace, a center brace and side braces.

| Works Croxx Plate II replaces the stock tubular braces with this solid aircraft aluminum plate. This is much stiffer than stock.

| Works Croxx Plate II replaces the stock tubular braces with this solid aircraft aluminum plate. This is much stiffer than stock.

The installation is easy, using all existing factory holes. No drilling is required. One bolt required popping a sill plate off and sliding an arm under the carpet but was still pretty straightforward. These braces make the stiff EVO chassis noticeably stiffer by making the whole car feel tighter, more responsive to steering input and the ride noticeably smoother. As a good side effect they also reduce minor squeaks and rattles. When going up a sloped driveway at an angle it is readily apparent that the car is really stiff since it can lift wheels off the ground when doing this. The Cusco power brace system is the most inclusive and effective undercar brace setups on the market and give big gains in both torsion and bending. Although our car isn't allowed to run with a cage, we've done the next best thing to stiffen it.

| When installing our Cusco Power Braces we first removed the slippery sticky undercoating from the areas where the brace would clamp to the chassis. We figured that this would help it work better.

| When installing our Cusco Power Braces we first removed the slippery sticky undercoating from the areas where the brace would clamp to the chassis. We figured that this would help it work better.

Our EVO came stock with some really nice 17x8 forged lightweight BBS wheels. We liked them but wanted to put on some wider, stickier rubber and needed to make room for the huge brake upgrade, which we eventually plan to do. Volk came to our rescue with a set of feathery light CE28N wheels. We obtained a set of 18x9.5 CE28Ns with a 35mm offset and a gunmetal finish. The 9.5-inch wide CE28Ns are 1.5-inch wider than stock. This width will help keep our tread flatter on the road and are wide enough so we can eventually fit some 275 tires in our EVO's wheelwells.

Unlike the typical inexpensive cast alloy wheel, the CE28N is forged from one piece of billet. Forging is usually reserved for parts that must be very strong, like racing pistons or suspension arms. With forging, a piece of aluminum alloy is smashed in a die in the shape of the wheel with about 15,000 tons literally smashing the aluminum into the wheels final shape. This violent force works the metal refining its grain to make it much denser, tougher, more ductile and stronger. The process also causes the metals grain to flow around the wheels shape, aligning it which the direction of stress giving the wheel more strength where it's needed.

| The Ultimate Mitsubishi Lancer Evo Suspension - Garage Tech

| The Ultimate Mitsubishi Lancer Evo Suspension - Garage Tech

These properties allow the use of thinner cross sections using less material. Since the material can be much thinner a forged wheel has the potential to be much lighter than a cast wheel of the same size. By forming the wheel into its final shape with a die, no machining other than for the backspacing controlling mount pad, the center bore and the lug bolt circle is needed. When fewer processes are needed in the production of the wheel, variability from wheel to wheel is reduced. This gives the potential for improved balance and less run out for each wheel, reducing the chances for wobbles and shakes.

Another plus is that if a forged wheel is hit hard, it tends to bend where a cast wheel tends to crack. This is much less of a catastrophic "soft" failure mode. Usually wheel forgings are reserved for the highest level of race car or very expensive road cars. We can attest to Volk's toughness, lasting many times longer than any other wheel on our race cars.

Race-ready wheels require race-ready tires and Nitto came to our aid with a set of their ultra-sticky 245/40-18 R-compound NT01 tires. Although it's a race-ready R-compound tire, the NT01 is designed and marketed not as an all-out gumball qualifying tire but as a high value race and track day tire for the serious grassroots enthusiast. This sounds a lot like us. The NT01's tread compound is formulated to last through many heat cycles and provide a decent amount of wear. This allows us to use the tire for street or track use, which is OK because we don't put a lot of miles on our EVO. It's not our primary source of transportation, even though we could drive it daily. The NT01 features a W performance rating for use up to 168 mph continually. It's carcass has hard bead fillers in the sidewalls to help steering response. A rayon carcass and nylon cord wrapped dual steel belts help ensure dimensional stability of the tire under high speeds and load. The tires feature a unique asymmetrical tread pattern that maximizes the treads contact patch putting lots of rubber on the road with minimal squirm.

| The center braces bolt solidly to the front center braces as well as to eight other points on the car, really tying the braces into the chassis.

| The center braces bolt solidly to the front center braces as well as to eight other points on the car, really tying the braces into the chassis.

To finalize our suspension install, we paid a visit to Steve Mitchell at M-Workz. M-Workz has been making quite a name for itself as a chassis setup facility serving the drift and road racing community. Steve spent half a day setting up our EVO with precision. Our chassis was set up taking full advantage of our adjustability. We set the front suspension at 5-degrees positive caster and 2.5-degrees negative camber - about the most you'd want to drive on the street and zero toe. The camber plates were set so that they were in the middle of the adjustment range with most of the adjustment being done at the bottom of the Moton strut housing so that more negative camber could be quickly dialed in at the track. M-Workz also used the lower adjuster to increase our steering axis inclination angle to improve straight line stability at high speeds and steering feel.

For the rear suspension 1.5-degrees negative camber was dialed in with zero rear toe. The lower rear camber numbers were so that the rear tires could sacrifice a little cornering power to get more drive out of the corner. After the alignment was roughly set, the car was corner balanced using electronic scales. With our uber-braced stiff chassis, it was easier than usual on a cageless street car to get the proper 50 percent cross weights. Since fiddling the ride height to get the corner weights affects alignment, the car was then fine-aligned to make sure that it was still dead on our specs.

So what do we think of our work so far. Well, we're still sort of in shock. Considering that our suspension is capable of winning races in professional road racing, the street ride is amazingly good, even over the broken pavement of LA. The EVO is a pretty stiff riding car from the factory and amazingly our creation doesn't ride much differently. It's firmer yes, but it's a good controlled stiff feeling - certainly not the jolting ride that's expected from racing suspension. The Moton dampers were good right from the factory that we haven't even attempted to adjust them. When we do get around to it, we bet the ride will be even better. Although there's more driveline and road noise due to the harder bushings and spherical bearings now in the suspension, it's really just a slight amount that some might not even notice.

| The side braces really help resist torsional twist.

| The side braces really help resist torsional twist.

One of the annoying things about an EVO is that the steering is so fast and responsive that the car can feel nervous at freeway speeds. With the addition of positive caster and additional steering axis inclination, the steering now has a better on/off center feel. There is more straight line stability while the turn in is even sharper. The amount of grip is amazing and the balance is so good that perhaps this may be the best handling car we've ever driven. Even though it's a street car, it handles better than most race cars we have tested and we can't wait to hit the track. We know that currently it's capable of pulling more than one g of lateral acceleration on the skidpad even with its current narrowish tires.

Once we increase power so we can use wider 275 tires without bogging down, we are sure it will get mind-boggling.