So, what are coilovers? Most people know they’re expensive, race cars use them, they’re expensive, some show cars have them, and they’re expensive. In the simplest definition, coilovers replace the stock shocks, struts, and springs on a vehicle and enable ride height and weight distribution to be adjusted with minimal effort. Most coilover systems also allow shock compression rates to be altered through the turn of a knob. One of the best features of coilover systems is how easy they are to install—many manufacturers ship their coilovers pre-assembled. But there has to be more to it, right?

Coilovers were designed with the racetrack in mind and performance as a primary concern. Through the use of scales that measure the amount of weight each tire supports, coilovers can be manipulated through compressing and uncompressing springs to give the vehicle more desirable weight distribution. No problem, right? This straightforward concept turns more complicated when a specific weight distribution is desired.

During cornering, weight transfers across the chassis diagonally. In other words, when entering a left-hand turn, weight travels from the left-rear to the right-front of the vehicle. This fact also holds true when adjusting coilover systems to achieve a desired corner weight. For simplicity’s sake, we’re going to use an example utilizing a Utopian car weighing 3,000 pounds. We’re also going to discount the driver’s weight and assume the car is perfectly symmetrical. By putting the car on scales that weigh each corner of the vehicle, we see that the left-front weighs 950 pounds, and the right-front weighs a similar 950 pounds. On the rear, both the left and right weigh 550 pounds.

Plain and simple, corner weighting is a difficult task that is time consuming (And did we mention difficult?—MAX). The process is so complicated that you must actually use some of the knowledge you attained in your advanced placement physics class in high school. The concept is fairly straightforward, but the actual practice will kick your butt. As we said, weight transfers diagonally, so the coilovers must be adjusted with the knowledge that when you adjust the right-front, the left-rear will be affected, too. But it doesn’t end there. Let’s say, for instance, that the right-front coilover spring is lowered. What affect will that have on the left-rear? When the spring collar is lowered, the weight resting on that corner will decrease. The weight resting on the diagonal wheel will, more often than not, decrease as well, but the weight resting on the other two wheels will be force-increased, depending on the chassis design. Each adjustment affects every corner, and that’s why the process of corner weighting gets so immensely complicated. In our hypothetical example, if we wanted to decrease the weight on the right-front wheel, the spring collar should be lowered. The weight on that wheel would decrease beneath 950 pounds, the diagonal wheel should decrease beyond its resting 550 pounds, and the left-front and right-rear resting weights should increase accordingly, as there must always be a constant weight pushing on the ground in a stationary car. A lot of little adjustments must be made at each corner, and detailed records must be kept in order to find out what worked and what didn’t and by how much.

This aside, let’s face reality: A great number of people purchase coilover systems for use on their show cars. In the case of show cars, coilovers are ideal because the suspension can be slammed at the show with few tools, then raised again for the drive home. After a car show, the suspension should be raised up to what is visually desirable for street use, making sure the wheels don’t rub against the fenders during cornering and also ensuring fender gap is equal on both sides. Show cars are usually not driven hard enough on the street to be concerned with correct weight distribution, so a simple visual inspection will usually suffice.

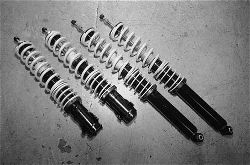

We mentioned earlier how simplistic coilover installations can be, and we intend to prove it. We headed down to Xclusiv Auto Center in San Diego, California, for a B+G Sport Suspension coilover install on a ’97 VW Golf GL already sporting B+G lowering springs. The B+G Sport Suspension coilovers simply bolt on, allow 12 shock compression settings, and offer a dual-spring setup, translating to softer initial shock compression on the road. After everything was installed, we experimented with the ride height from as low as it would go to as high as we could get it, as this VW’s primary use will be in car shows. After playing for a while, we set the suspension for street use with little more than a car jack, a tape measure, and an Allen wrench, and then we drove home.