Mitsubishi's turbocharged 2.0L 4G63 has long been one of the most powerful and reliable four-cylinder engines available. The Mitsubishi Lancer Evolution IX version is rated at 286 horsepower, offering an impressive 143 horsepower per liter. Even more remarkable is the potential power that can be unleashed with very few modifications. For this reason, few EVOs roaming the streets today are left unmodified. The quest for more power often includes common modifications such as a high-performance exhaust, larger turbocharger and ECU recalibration. These are all effective methods of increasing output, but limitations such as fuel octane and engine displacement will eventually cap the tuner's ability to generate more power. Furthermore, the lack of mid-range torque can leave a lot to be desired from those using their car for daily driving. The solution to this problem is obvious: build a bigger engine and feed it with better fuel. Stroking the engine to 2.3 liters with a 100mm 4G64 crankshaft is the most common way to increase displacement, but after a little digging, we discovered that some 4G64 blocks-found in vehicles ranging from Mitsubishi trucks to the non-turbo Eclipse-are almost a direct replacement for the EVO's 4G63 block, and can be stroked to a true 2.4 liters. And with E85 pumping stations on the rise, it seemed clear that our goal for more displacement and better fuel was within reach. With 2.4-liters of corn-powered goodness fresh in our minds, the search for parts began.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

What is our ultimate horsepower goal? Your guess is as good as ours. To date, we have yet to see anyone run our unique combination of parts, so we don't have a clue. But if we had to put a number on it, we'd be guessing in the range of 550 to 600 hp. But of course, if all things pan out smoothly, you can bet we won't hesitate to increase boost and generate some tasty dyno numbers to put this custom build officially on the map.

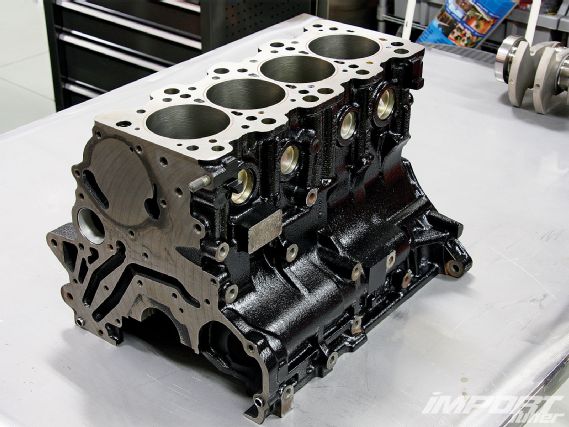

Enter The 4G64 Block

The 4G64 block is nearly identical to the 4G63 used in today's EVOs. The 4G64 is essentially the same casting, but features a 6mm-taller deck height, 1.5mm-larger bore (86.50 mm), and no oil squirters for the pistons. Since we plan on installing this engine in an EVO IX, a newer 4G64 block with the proper orientation and oil drain backs was needed to work with the existing components. In this case, a '00 Mitsubishi Galant engine was our pick. And after 160,000 miles of grocery runs and mad-dashes to soccer practice, it was obvious that this block would require some work to bring it back to life.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

Mivec Oil Feed

The 4G64 block was taken to LESCO Race Engine Development for machine work. LESCO has years of experience machining Mitsubishi blocks, most of which from behind the scenes for some well-known customers. Their first step was to machine ours to accept oil squirters from the 4G63. Although the engine can be used without oil squirters, the extra flow of oil to the piston undercrown and wrist pin helps keep moving parts lubricated and at a lower operating temperature. Using a spare 4G63 block as reference, LESCO utilized their CNC mill to trace the OEM location of the oil squirters and create a CNC program to add them to the 4G64. The extra effort resulted in a perfect replica of the OEM squirter bosses that LESCO could easily reproduce in the future. Before removing the block from the CNC Mill, the threaded passage to the oil gallery on the intake side of the block was drilled and tapped to accept the MIVEC oil feed line.

Next, the mains were lightly honed and measured to ensure they were within specification. The crank journal mains checked out and the block was honed to clean up the bores. The 4G64 block has a maximum bore size of about 87.5 mm, but for most high-performance applications, it is advisable to select a smaller bore size to ensure proper cylinder wall thickness. The extra thickness helps reduce bore distortion, and improves piston-ring and head-gasket seal. Cylinder wall thickness can also vary from block to block, due to core shift during casting or other manufacturing factors. For this reason, LESCO checked the cylinder wall thickness with a sonic thickness gauge before removing any material from the bores. The bore thickness turned out normal, but it was decided to simply hone the block slightly until the bores were straight and round. After honing the block, the deck was resurfaced and the block was again sent to the CNC mill for one last operation.

One concern when using a 4G64 block is the lack of good head gaskets for the larger bore size. Furthermore, finding a large-bore gasket specifically designed for the MIVEC cylinder head we'd be using proved to be difficult. Tim Salefski at AMS Performance recommends adding a copper O-ring to the deck of the block, along with an AMS modified EVO IX head gasket with a larger bore opening. After installing the .040-inch copper wire in the deck, the block was final cleaned, packaged and shipped back for assembly.

Billet Crankshaft

With the block in new condition, it was time to select the rotating assembly components. The bore was left very close to standard, so a longer-stroke crankshaft was needed to increase displacement. Fortunately, there are many aftermarket crankshafts readily available that offer strokes from 92 mm to 106 mm-a significant increase from the standard 88 mm stroke found in the EVO. The desire for torque resulted in the purchase of a Brian Crower (BC) 102 mm billet crankshaft. The new BC crankshaft will help increase torque and bump displacement up 20 percent to our target 2.4 liters. All Brian Crower crankshafts for Mitsubishi engines are 100-percent machined from new 4340 steel billet and feature large radii on each journal for improved strength and durability. The nicely polished journals were measured with a digital micrometer and found to be the perfect size. The BC crankshaft was installed in the block with ARP main studs and WPC-treated ACL main bearings.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

H-Beam Rods

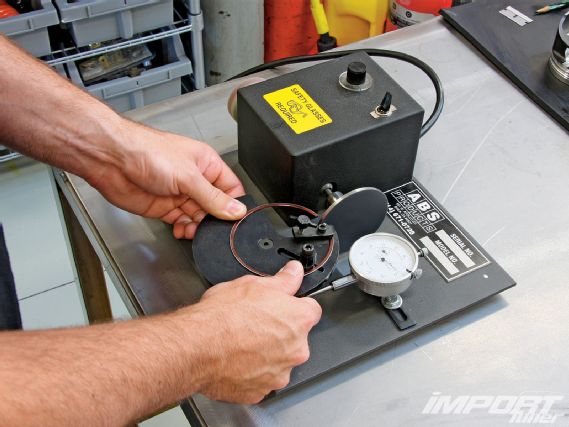

If the standard 150 mm rod was used with the 102 mm BC crankshaft, the rod-to-stroke ratio would become slightly worse than the already marginal OEM ratio. To counter the effects of the longer-stroke crankshaft, Brian Crower 152.4 mm (6-inch) H-beam rods were selected to help restore the rod-to-stoke ratio to near-OEM levels. The improved ratio will help reduce side loading on the pistons and cylinder walls, therefore increasing piston and component life. The BC rods feature high-quality ARP 625+ bolts that require 0.0063-0.0067 inches of stretch for correct preload. Checking rod-bolt stretch is the only way to ensure accurate clamping force between the rod and rod cap, since friction between the threads and bolt head can cause the torque method to vary significantly. In this case, a point micrometer was used to measure the bolt stretch after they were installed with WPC-treated ACL rod bearings.

Custom Designed Pistons

Despite the fact that the rods and crankshaft are available off the shelf, the required piston design is less than ordinary. Fortunately, JE Pistons was able to manufacture custom pistons for this combination in under three weeks. The wrist pin location (the distance between it and the top of the piston known as "compression distance") was changed to properly locate the piston top relative to the deck of the block. The remaining piston features, such as skirt and crown thickness, were adjusted to handle the stresses associated with the longer stroke and increased cylinder pressure. JE also added their "Tuff Skirt" coating to reduce wear on the piston skirts and "diamond-like carbon" coating (DLC) to the wrist pins. JE Pro Seal rings were matched to the pistons to seal combustion pressure and maintain oil control. Once installed, the pistons provided a pump-gas- and E85-friendly 9.0:1 compression ratio.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

ATI Crankshaft Damper

One component often overlooked when building a high-performance engine is the crankshaft damper. When the engine is running, the crankshaft is being pushed and pulled in different directions due to the various forces related to the engine's four-stroke cycle. These stresses cause the crankshaft to "twist" and can become problematic if not controlled properly. To resolve this issue, we called ATI Performance and purchased a Super Damper. ATI's dampers significantly reduce torsional crankshaft vibrations (twist), which helps to increase engine and component life. The damper included a press-fit hub that installed easily on the front of our BC crankshaft.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

Aluminum Oil Pan

The OEM oil pan works well for street applications, but is not specifically designed for the effects of high-speed corning and extended track time. We picked up the new AMS aluminum oil pan to help keep our engine safe at the track. The oil pan holds an extra 1.5 liters of oil for better cooling, and features a trap door designed to maintain a constant supply of oil to the pickup. The kit even included a crankshaft oil scraper and all the necessary hardware for installation.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

Project 4G64 MIVEC

Check back as we progress deeper into our 4G64 build, covering intimate details on porting the cylinder head, addressing the drivetrain, and bolting on some go-fast goodies to propel our soon-to-be daily driven EVO.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge