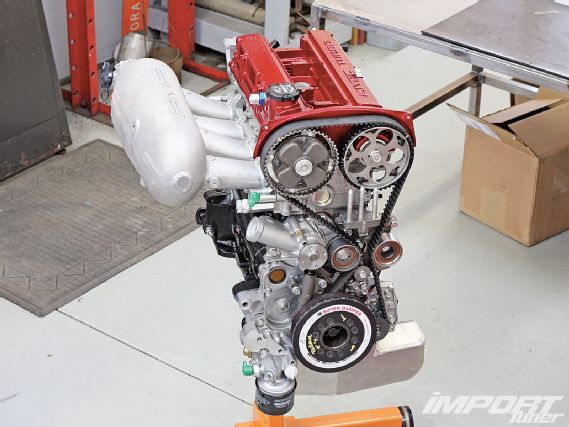

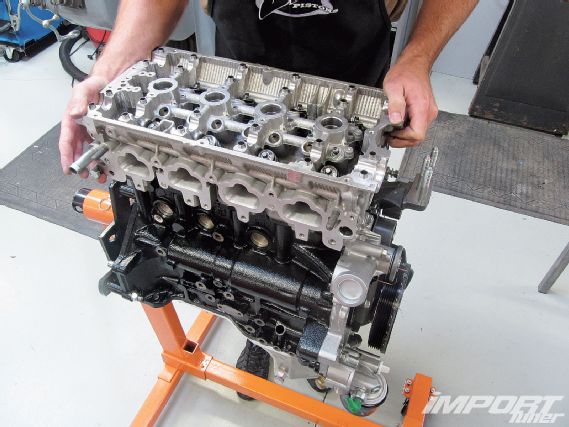

In part one of our 4G64 installment, we set out to find the best engine combination to improve the power and response of our stock Mitsubishi Evolution IX without affecting street drivability. We determined that the stock 2.0L engine would limit our goals for usable, low/mid-range power, and opted to build a larger, 2.4L engine based on the 4G64 short block. We covered the build of the bottom end in last month's issue, including all the necessary components to support our high horsepower build-parts that included a billet Brian Crower (BC) crankshaft and rods, custom JE Pistons, and ARP fasteners. With a solid bottom end ready to go, we turn our focus to the cylinder head, valvetrain and intake manifold.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

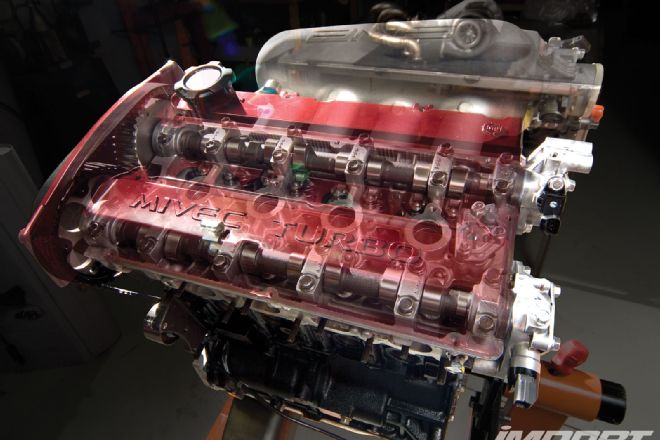

Cylinder Head

Many 4G63-powered cars use the factory cylinder head to obtain 500 whp without any modifications. Although the stock head works great with a 2.0L engine, our 2.4L engine is 20-percent larger and will require more air flow to reach our target power of 550 to 600 hp. To solve our problem, we sent the stock MIVEC cylinder head to Craig Gerfen at Race Engine Systems for proper modification. Craig has experience working on a plethora of cylinder heads, including those of top-fuel dragsters making over 900 hp per cylinder. After reviewing our goals with Craig, he calculated the engine's required airflow and began working his magic.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

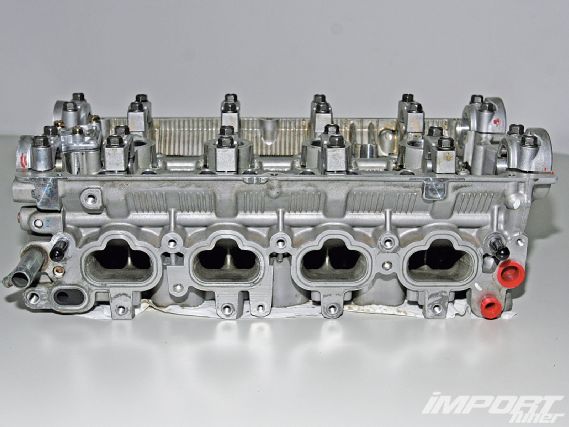

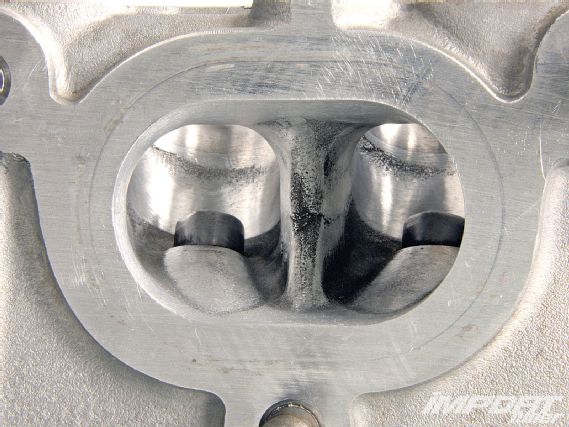

Port Design And Valves

According to Craig, the 4G63 MIVEC cylinder head has a small valve area (diameter) relative to port size for a 2.0L engine that operates in the 7,500 rpm range. Despite the "small" valves, Craig felt that modifying the port design while maintaining the stock valves would produce the most favorable results for our power goals, while keeping the cost down. Like valve sizing, port design is critical to ensuring optimal performance from the cylinder head. In many cases, it's easy to chase high flow numbers when porting a cylinder head, but often at the expense of velocity. Craig focused on maintaining peak velocity by paying close attention to where and how much material was removed from the intake and exhaust ports. Ultimately, his goal was to improve the engine's volumetric efficiency (VE), or the ability to fill the cylinders with air and fuel. The higher the VE, the more air and fuel can be pulled into each cylinder before combustion takes place, creating power throughout the engine's range with improved throttle response. On the contrary, a poorly designed port with reduced velocity can decrease VE, leaving you with decreased low-end and mid-range power. Simply grinding away at your stock head without proper direction can hurt your engine's performance.

Intake Port

The largest restriction in the intake port was found at the inlet divider where one port becomes two. Craig found the largest improvements in flow when working in each of these areas. As the intake port was widened, the corner radius was reduced and the divider between the ports was narrowed to increase area. He then blended the seats and short-turn radius to match the increased size of the port, while paying close attention to total area to ensure good velocity. The finished port maintained a specific taper in each runner and showed favorable results on the flow bench.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

Exhaust Port

Unlike the intake port, the exhaust port did not require extensive work. Craig felt the area was sufficient for our combination, and simply blended the short turn-radius and smoothed the bowl and valve seat area. These simple modifications were able to improve flow significantly, with only a small increase in port size.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

Combustion Chamber

The combustion chambers were smoothed and polished to reduce the likelihood of hot spots, cracking and pre-ignition. Polishing the chamber also reduces the area of heat absorption by smoothing the granular texture of the casting process, therefore reflecting more heat back into the chamber, increasing efficiency.

Valve Springs And Retainers

After the port work was completed, Craig cut multiple angles on the valve seat, resurfaced the valves and checked the valve tip height for optimal clearance. The stock valves were reassembled with Ferrea Beehive valve springs and titanium retainers. The Ferrea Beehive valve springs (also known as conical valve springs) are wound with ovate (oval) wire and feature a smaller outside diameter at the top of the spring. This beehive shape improves spring stability and allows for a smaller retainer, therefore minimizing weight in a critical valvetrain area. When combined with lightweight titanium retainers, the process of opening and closing the valves can take place quicker and easier. The oval shape of the wire improves the distribution of stress over the spring and helps dissipate heat, a leading cause of valve spring fatigue. The combination of these technologies results in a longer life for our street-bound engine.

Results

After the porting and valve job were completed, the ported head achieved up to 25 percent more flow from the intake and seven percent from the exhaust, while maintaining velocity. Needless to say, were very happy with the results and quality of work.

|

The tests were performed at 28 in. hg on a SuperFlow SF-600 flow bench, with a FlowCom, 85mm sleeve, clay radius inlet and no exhaust pipe.

INTAKE

Lift (inches)

.100

.200

.300

.400

.450

.500

(CFM)

Stock

83

155

211

222

223

218

Ported

86

169

234

262

269

274

EXHAUST

Lift (inches)

.100

.200

.300

.400

.450

.500

(CFM)

Stock

80

148

196

215

217

217

Ported

83

153

209

228

230

232

|

The tests were performed at 28 in. hg on a SuperFlow SF-600 flow bench, with a FlowCom, 85mm sleeve, clay radius inlet and no exhaust pipe.

INTAKE

Lift (inches)

.100

.200

.300

.400

.450

.500

(CFM)

Stock

83

155

211

222

223

218

Ported

86

169

234

262

269

274

EXHAUST

Lift (inches)

.100

.200

.300

.400

.450

.500

(CFM)

Stock

80

148

196

215

217

217

Ported

83

153

209

228

230

232

Head Studs

The use of a larger turbo, more aggressive camshafts and E85 fuel necessitated the purchase of upgraded head studs. As cylinder pressure increases, so does the amount of energy trying to lift the cylinder head from the block. To ensure the head will stay fastened, we picked up a set of Titan Motorsports/AMS L19 head studs. These studs are factory size, but are manufactured from ARP's L19 material with a 230,000psi tensile strength. The higher tensile strength allows the studs to be torqued to 100 lb-ft, which provides a significant increase in clamping force. When compared to standard bolts or studs, these head studs will withstand more cylinder pressure before allowing the head to lift.

|

Mitsubishi Lancer Evolution - Tech Knowledge

|

Mitsubishi Lancer Evolution - Tech Knowledge

Cam Timing And Piston-To-Valve Clearance

When selecting camshafts, we wanted a design that would offer a substantial power increase in the mid-range to upper rpm level, while maintaining good idle quality and low-speed drivability. Kelford's popular 272-degree duration camshafts fit our needs nicely, and the exhaust cam was coupled to a BDL adjustable cam gear sprocket. The camshafts are available off-the-shelf and have a good reputation for use in daily drivers.

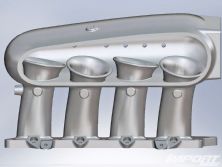

AMS F1i Intake Manifold

After spending so much time perfecting the cylinder head, we knew the stock intake manifold wouldn't make the cut. We found the ideal solution in the AMS Performance F1i. AMS spent two years designing the new cast aluminum intake manifold with claims it will provide up to five percent more power than their popular VSR manifold. The extra engineering effort showed, as the F1i has many features pulled straight from the racing world. The manifold plenum contains large internal velocity stacks and tapered runners that keep air moving quickly and easily into the cylinder head, along with a larger throttle body opening that allows more air into the plenum, and can be fed by a stock Mitsubishi or 4.6L Mustang throttle body. Several accessories such as a custom dipstick tube, vacuum fittings and a stainless steel support bracket are also included.

Throttle Body

Our OEM Mitsubishi throttle body lacked the flow capacity we needed and was replaced with a factory version modified by Milspec. The factory throttle body bore was opened up from 60 to 65mm to allow airflow to match the opening of the AMS F1i intake manifold, and MILSPEC also replaced the throttle body shaft seals with upgraded versions that eliminate boost leak. The entire assembly is a direct replacement and operates like the original equipment.