| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

For months on end leading to the debut of the newest Mitsubishi Evolution, anticipation ran high among automotive enthusiasts as they sat patiently licking their chops for their chance to purchase the new Evo x. when the time had finally arrived, interestingly enough the added hype we had seen within the past few months has been met with a flurry of mixed emotions and cautious buyers.

Green Giant

Word on the street had quickly risen that Evo x's new 4B11 powerplant used a smaller exhaust camshaft with less lift and duration. Adding to the troubling news was Mitsubishi's new outlook on going environmentally green that was relevant even on the new Evo, as they implemented environmentally friendly exhaust valves that eliminated the once sodium-filled valves found on the Evo Ix. These minor changes paled in comparison to the shocking news that Mitsubishi's cast-iron block, which offered exceptional durability in all previous models, was replaced with a more conventional open-deck aluminum-alloy setup.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

Preliminary news for the Evo x was looking grim for Evo enthusiasts and those reporting on the findings. Or at least that was until we received exciting news that the 4B11 engine had been carefully reverse engineered by Tomei Powered of Japan. Tomei engineers have diligently studied the 4B11's internal design in order to fully educate themselves before even attempting to lift a finger in fabricating high-performance aftermarket products. Now that's what you call dedication, folks. From the valvesprings to the piston design, Tomei Powered has carefully analyzed and recorded every conceivable part on the engine to the minute detail with some positive results. Prepare yourself as the Tomei engineers spit knowledge and breakdown the newest Mitsubishi 4B11 engine while comparing it to the previous 4G63 powerplant in their official Evo x Technical Report.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

The Obvious Difference

Following the public release of the Mitsubishi Evo x, Tomei Powered quickly acquired and disassembled the newest 4B11 powerplant to begin their research. Tomei's first step toward research proved crucial for the development of their own 4B11 products as it involved familiarizing and discovering the basic characteristics of Mitsubishi's new engine design. Another aspect of this research included a side-by-side comparison with its predecessor, the 4G63. This comparison was significant for the Tomei engineers as it provided further insight on how this engine is going to be modified and its potential capabilities. The first and most obvious change from the 4G63 to the new 4B11 was the rocker arm-type valvetrain being replaced with the 4B11's direct acting unit and the timing belt being replaced with a silent-chain setup. The MIvEC feature, which was only available on the intake side on the latest version of the 4G63, was now available on both intake and exhaust on the 4B11, offering a wider range in powerband while keeping eco-friendly with emissions was the general focus for Mitsubishi engineers when building the engine.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

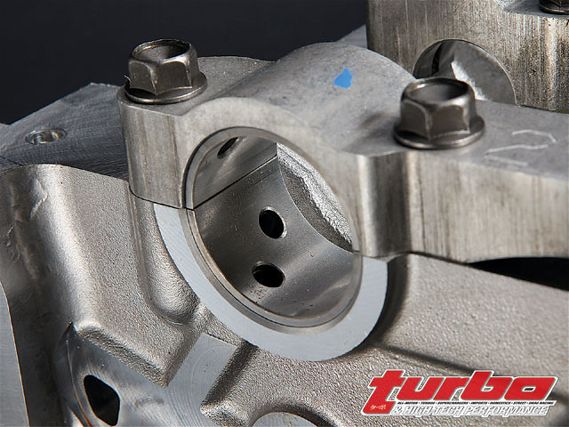

Bearings Adopted Onto Exhaust Side Cam Journals

Several devices equipped on this engine indicate that the engineers at Mitsubishi have paid particular emphasis on the 4B11's oiling system design. On the exhaust side camshaft, the No. 1 cam journal was equipped with bearings since it's furthest from the oil line. This bearing adaptation was implemented to increase reliability and decrease friction within the cam journals. Thicker oil lines were also installed to supply an increased amount of oil due to the existence of the MIvEC system.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

Highly Efficient Cylinder Head Engineered For Low Emissions And Power

The cylinder design was well thought-out and engineered by Mitsubishi with balance in mind. The design included engineering an area where the piston top geometrically matches well with the combustion chamber design. By looking at the piston design, it doesn't resemble the conventional forced-induction profile, but looks to be designed to that of a low-emissions engine. The intake and exhaust ports have large-diameter ports for improved efficiency. The low-emissions-producing design was also made with the MIvEC feature in mind.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

Bigger Valves And Plugs With Decreased Diameter

Upon measuring the cylinder valves, the 4B11 consists of 35mm intake and 29mm exhaust valves. The 5.5mm valve stems reveal that the new valves are definitely larger than that from the 4G63. with these increased factors, the spark plug size was decreased to optimize valve seat and spark plug hole clearance. Compared to an sR unit with the same bore, the intake is shown to be bigger by 1mm, while the exhaust valve is smaller by 1mm.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

Exhaust Valve Designed With The Environment In Mind

The exhaust camshaft was found to have less lift and angle than the previous 4G63 model. The objective of the 4B11 camshaft was designed to produce a cleaner exhaust gas while exhibiting good power output with the help of MIvEC. The sodium-filled valves found in the 4G63 have now been replaced with standard surface-treated units, which were considered for environmental reasons. Tomei Powered engineers have reason to believe a drawback with the 4B11 exhaust valves may be prone to heat damage since the seat rings and valve guides weren't manufactured with copper materials.

Camshafts With No Rocker ARMS

The rocker arm setup was tossed aside for a direct acting configuration. This new setup means that there are less moving components needed for operation, allowing for a compact design with less mechanical trouble and friction, which the camshaft lobes benefit from the most. The camshaft specs measured in at 254-degrees intake with 9.4mm lift and 224-degrees exhaust with 8.2mm lift. valve lifters, which were measured at 35mm diameter and 23.9mm height, were combined with shims that allow valve clearance adjustments also found on the new 4B11 engine. For those who consider altering this area in the near future, Tomei engineers have found the lift can be raised 2mm and the valvesprings and lifter nose should clear-if the base circle has been kept standard.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

Lightweight Valvesprings

The lifters, retainers and valves were noticeably different in design compared to previous engine models with the focus of lightweight engineering in mind. Tomei engineers found that the valves have plenty of room from bottoming out but the 4B11 spring rates are rated fairly low. Therefore, in terms of tuning aspects, these might need to be replaced to a stiffer aftermarket set depending on the camshaft profile and lift.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

Mivec On Intake And Exhaust

The 4B11 was engineered with clean, environmentally friendly emissions while delivering a significant amount of power. The MIVEC feature (4B11 engine uses MIVEC on both intake and exhaust variable valve timing systems) is mainly responsible for this great balance of two opposite features. Even though the Evo Ix 4G63 was equipped with the variable valve timing on the intake side only, the 4B11 proves to have added improvements on low to midrange torque. The MIVEC is controlled with an ordinary vein that partitions two different chambers managed with two different pressures.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

4G63 Timing Belt Replaced With Silent Chain

A silent chain instead of the traditional timing belt powers the 4B11. Chains are beneficial over belts due to the lack of friction loss and increased longevity. The front timing cover consists of a single unit not split into upper and lower sections, which create a problem when servicing or performing modifications such as head/block resurfacing or a headgasket change. Tomei engineers found that compression changes can be more troublesome when altering the 4B11 engine.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

Metal Headgasket

The headgasket is measured at 0.9mm thick and consists of a five-layer laminated-metal type. due to the laminated headgasket design, proper head seating issues may occur after modifying the engine.

Stretch-Type Head Bolt Angle Tightening Method (Torque To Yield Torque Procedure)

The torque to yield method used elastic stretch-type bolts to tighten the 1mm length head bolts. since the engine has an aluminum block, the bolts are longer with increased torque specs. The washers on the bolts are fixed except for No. 1 for the ease of service and maintenance.

| Tomei Technical Report - Garage.Tech

| Tomei Technical Report - Garage.Tech

To be cont...

Stay tuned for part two as we move into the bottom-end cylinder block and turbo system and see what Tomei engineers have found when comparing the 4B11 setup to the 4G63.