| Automotive Plumbing - The Art Of Fluid Dynamics: Part One Of Two - Wrenchin'

| Automotive Plumbing - The Art Of Fluid Dynamics: Part One Of Two - Wrenchin'

Anyone who's attempted a buildup has probably found themselves installing fluid components like steel braided hose, aluminum fittings and specialty adapters. Thread sizes, thread pitches and sealing surfaces, however, can be difficult to interpret and AN (Army Navy) plumbing, as it's commonly known, can be a complex thing. AN plumbing was developed by the aerospace industry as a military standard but its usefulness in terms of your Honda are many.

Understanding the pros and cons of such plumbing is important. Few people get the basics yet settle upon such upgrades nonetheless. This lack of understanding has led more than a few on an exploratory trip down the Home Depot plumbing aisle only to return with something suitable for a bathroom sink, not a B-series. Alas, this is where the fine line between automotive plumbing and home improvement swelters into a giant gap. Granted, the brass parts bin is tempting-such fittings are less expensive than their aircraft-style aluminum counterparts and are arguably easier to source, however, the differences between the two are many, despite the outward appearances.

Ill-informed plumbing know-how can lead to eye-catching, public displays of destruction, like those derived from fuel and oil leaks, and the consequences of their coming into contact with scorching hot exhaust components. Although spontaneous roadside displays of fire can be quite the spectacle, especially at someone else's expense, plumbing a car properly remains the preferred option. Understanding the fundamentals, being sure to select the correct hose, adapters and hose ends is a simple insurance policy against catastrophic failure.

| Eliminating OEM-issued hard brake and clutch lines isn't always a good idea. Flexible steel braided hose can result in a mushy, less responsive pedal. Of course, factory-issued rubber brake and clutch lines are fair game. Oftentimes, adding aftermarket hard line when running new sections of brake or clutch lines is a better idea than lengthy sections of flexible hose.

| Eliminating OEM-issued hard brake and clutch lines isn't always a good idea. Flexible steel braided hose can result in a mushy, less responsive pedal. Of course, factory-issued rubber brake and clutch lines are fair game. Oftentimes, adding aftermarket hard line when running new sections of brake or clutch lines is a better idea than lengthy sections of flexible hose.

Steel Braided Hose: There Are Two Kinds

Most associate competition plumbing with stainless steel braided hose paired with shiny red and blue fittings but there's much more to it. Internally, steel braided hose is comprised of synthetic rubber or Teflon. In the case of rubber, a steel braided sheath is embedded into the hose with a second sheath covering its outside. Rubber-based hose is best suited for oil and fuel lines-both for pressure and temperature-as well as cooling system and fuel lines. Typical operating temperatures range from minus 40 degrees F to as high as 300 degrees F, depending on the brand. The other type of steel braided hose utilizes extruded Teflon, which is also covered with a protective steel braiding and is pressure tested as high as 4,000 psi. Teflon-based hose is conducive to hydraulic systems, like those for clutches and brakes but can be used for most anything, including certain exotic fuels typically not compatible with rubber.

Contrary to popular belief, steel braided hose is not always superior nor is it invincible and it does have its downsides. Rubber-based braided hose features larger bend radiuses when compared to OEM rubber hoses, which can make fitment difficult. Steel braided hose is also abrasive and can easily rub holes into softer materials, like rubber radiator and cooling hoses. Engine vibrations that can cause steel braided sheathing to wear against harder materials can damage the hose itself-whether rubber or Teflon-causing a rupture when subjected to pressure. Steel braided hose is also not particularly suitable for slipover barb fittings or clamp-down applications since the braid prevents both the expansion and contraction of the hose and barb. If you must use a hose clamp, you might want to consider an alternative hose. Of the two types of steel braided hose, rubber-based is the more pliable. Although similar in appearance, Teflon-based hose is stiffer and requires entirely different fittings and assembly procedures. Earl's Teflon-based Speed-Flex hose works only with their Speed-Seal hose ends that use brass olives for sealing against one another.

| Teflon-based Speed-Flex hose from Earl's lends itself well to turbocharger feed lines. Feed line size should be approached carefully because erring on the small side can result in excessive pressure while erring on the large side can result in too much volume. It's best to consult with your turbocharger manufacturer for size suggestions.

| Teflon-based Speed-Flex hose from Earl's lends itself well to turbocharger feed lines. Feed line size should be approached carefully because erring on the small side can result in excessive pressure while erring on the large side can result in too much volume. It's best to consult with your turbocharger manufacturer for size suggestions.

Realistically, braided hose should only be used when warranted and when properly installed. Replacing factory Honda hoses for the sake of some added bling only makes sense when a complete AN conversion is in order, which incidentally won't hurt the bling factor either.

Hose Materials

The hose market is massive, with material selection and rubber chemistry varying to suit several applications. The fluid to be carried makes a difference as to which hose to go with, whether it's gasoline, alcohol, oil, brake fluid, water or power steering fluid. For example, rubber hose used to deliver fuel, like Earl's Super Stock hose that doesn't feature a steel braided sheathing, is quite different from rubber hose designed to withstand complete fuel system immersion, like Gates G4H hose. G4H doesn't soften or dissolve, even when bathed in fuel. On the same note, steel braided hose like Earl's Perform-O-Flex hose shouldn't be immersed in fuel either, since steel conducts electricity and, in some cases, can deliver a static discharge to the fuel tank resulting in combustion.

Chemically, the synthetic rubber commonly used in steel braided applications is less versatile than OEM hose compounds. Steel braided synthetic rubber can crack over time, without visible warning. However, Teflon-based hose can withstand a wider range of chemicals, like varying fuels, and can last significantly longer assuming it doesn't melt. The general misconception is that steel braided hose is invincible. It's often mounted close to exposed timing belts, even draped across blazing hot manifolds. Like any other hose, even steel braided ones can't withstand timing belt-induced abrasions or turbo manifold temperatures. Earl's offers a number of other hose materials including its Pro-Lite 350 hose, which features many of the characteristics of a steel braided hose but without the weight. Of course, these too are not invincible.

| Automotive Plumbing - The Art Of Fluid Dynamics: Part One Of Two - Wrenchin'

| Automotive Plumbing - The Art Of Fluid Dynamics: Part One Of Two - Wrenchin'

Hose Considerations

Steel braided hose and AN fittings are measured in 1/16-inch increments. Therefore, a -6 hose has an internal diameter of approximately 6/16 of an inch, or 3/8 of an inch. We say approximately since AN sizes correlate to the diameter of the hypothetical tube that could potentially fit inside the proposed hose. Sound confusing? It can be since tubing wall thicknesses vary, which can make one company's -6, 3/8-inch diameter hose slightly smaller or slightly larger than 3/8 of an inch. Common AN sizes include, but are not limited to, -3, -4, -6, -8 and -10 although larger sizes and oddballs like -2 and -5 are also available and are also more expensive due to their rarity.

There are three factors to consider when selecting a hose: the fluid itself, the fluid's operating temperature and the system pressure. Typically, rubber-based steel braided hose suits most Honda applications excluding hydraulic systems like brakes, clutches and power steering. Operating temperature and system pressure should be considered together to determine the appropriate material. Typically, rubber-based, steel braided hose operates exceptionally well under extreme temperatures but isn't conducive to higher pressures. Generally, high-pressure components, like brake and clutch systems, don't exhibit the same heat characteristics as cooling and oil systems do so the two rarely contradict. Steel braided hose featuring synthetic rubber internals can handle higher pressures than its non-reinforced Super Stock rubber equivalent but should not be used for high-pressure applications like power steering, brake lines or clutch lines. Teflon-based steel braided hose like Earl's Speed-Flex should be used in these cases while Earl's triple steel braided power steering hose is recommended for abnormally high-pressures like those exhibited by power steering systems.

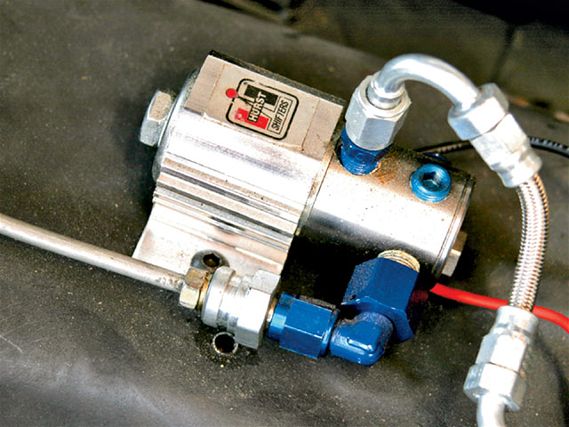

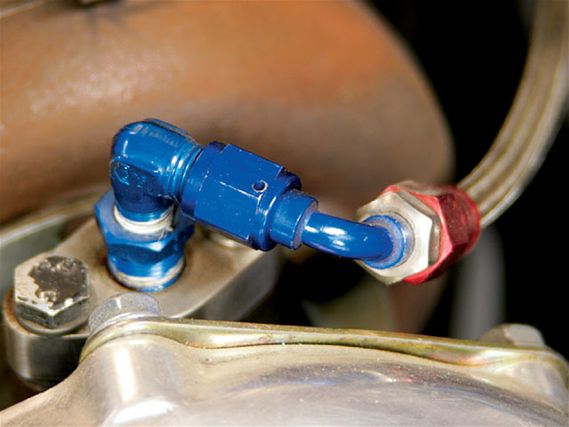

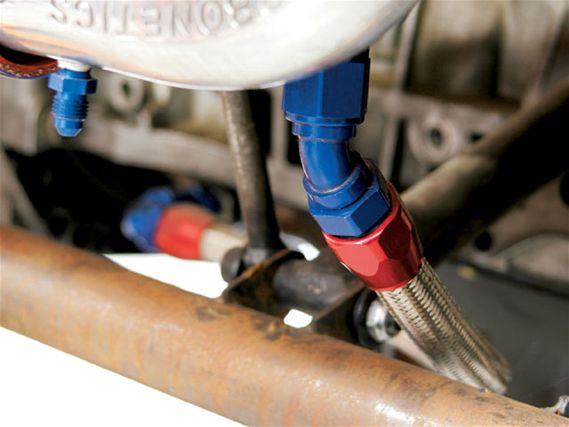

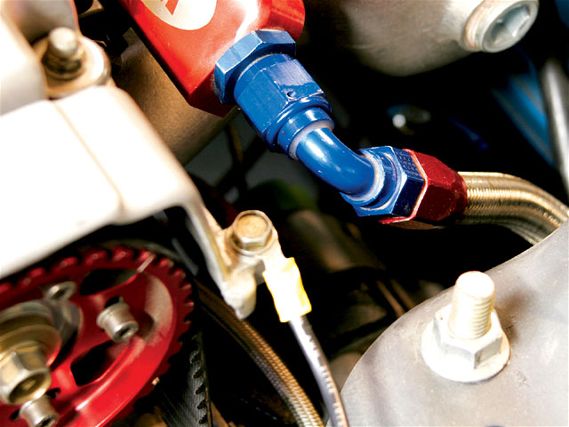

| Turbocharger oil drain lines sized with -10 hose and fittings allows for an easy drain path for this low-pressure stream of oil. Configuring the setup with properly oriented hose ends negates the need to bend the hose itself, resulting in a smoother path.

| Turbocharger oil drain lines sized with -10 hose and fittings allows for an easy drain path for this low-pressure stream of oil. Configuring the setup with properly oriented hose ends negates the need to bend the hose itself, resulting in a smoother path.

Pressure vs. Volume

As hose size increases, its pressure handling capabilities decrease, although this is usually not a problem since pressurizing liquids at larger volumes becomes increasingly difficult thus requiring a more capable pump. This is precisely why using -8 hose instead of -6 hose in a LS-VTEC application may actually reduce the pressure in the system, preventing proper VTEC solenoid activation. Conversely, using a smaller -3 hose can provide insufficient volume for properly lubricating the components.

Beware of the difference between a hose's maximum pressure rating and its much lower operating pressure. A typical -6 steel braided synthetic rubber hose like Earl's Auto-Flex has a maximum operating pressure of 1,500 psi but works quite comfortably in the 350-450psi zone when paired with hose ends. Of course, this is well within the limits of an LS-VTEC setup. Run such a setup on a 500-plus psi application though and you can expect those hose ends to leak, if not blow off.

Practical Applications: Brake And Clutch Lines

Dumb decisions abound when it comes to selecting the correct hose size. The "bigger is better" philosophy is usually to blame. For example, using -4 steel braided Teflon hose to construct an entire braking system results in decreased pressure and a mushy pedal. However, -4 Teflon hose reinforced with stainless steel when used with a hydraulic clutch line is acceptable due to the larger volume required to move the slave cylinder. Flexible brake lines, especially those for calipers, should be constructed with -3 steel braided Teflon hose, which allows the brake master cylinder plunger's relatively small displacement to adequately build pressure, forcing the pads against the rotors. It's not uncommon to use -2 brake lines on expensive and more precise brake systems, like those used on Formula 1 cars, but on Honda's less precise floating calipers, -3 hose works just fine and is significantly less expensive. Keep in mind that anytime the OEM hard brake lines are replaced with flexible, steel braided hose-like when performing a brake line tuck-pedal firmness and braking performance will suffer. One need only watch what happens to the lines once the pedal is depressed. Flexible brake lines are less rigid than solid tubing, even with its outer steel braiding. The same theory can be applied to clutch lines where larger lines can decrease pedal firmness, even affect clutch engagement. All of this isn't to say custom brake lines are a bad idea-they're not-especially when suspension travel has been modified, but replacing OEM hard lines with flexible hose is rarely beneficial.

| Many OEM and auto parts store hoses, like this low-pressure-minded rubber hose, simply aren't sufficient when it comes to the higher temperatures and pressures associated with high-output engines. Avoid disaster and step up to the good stuff to begin with.

| Many OEM and auto parts store hoses, like this low-pressure-minded rubber hose, simply aren't sufficient when it comes to the higher temperatures and pressures associated with high-output engines. Avoid disaster and step up to the good stuff to begin with.

Practical Applications: Turbocharger Lines

Similar to hydraulic systems, -3 or -4 steel braided Teflon hose also works well for turbocharger oil feed lines, however, a -4 line will deliver more volume with slightly less pressure. Generally speaking, evidence to show that one size is better than the other is controversial, and it's best to consult individual turbocharger manufacturers for their recommendations because certain CHRAs have volume and pressure preferences when it comes to ideal shaft lubrication and cooling. Some CHRAs even require restrictors to avoid blowing out seals. It's best to research such pressure requirements prior to settling upon a particular hose size.

When plumbed properly, turbocharger drain lines should be constructed with -10 steel braided hose, not scary rubber cooling hose contraptions paired with worm gear hose clamps. However, -10 hose is not particularly flexible when working with a typical short-run section spanning between a turbocharger and oil pan. Exact length sizing and hose end rotation is crucial in order to prevent kinks. Pressure on this side of the turbocharger is minimal, so proper line construction is important to maintain unobstructed flow and allow gravity to do its job.

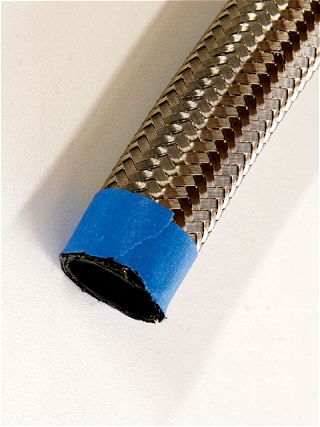

| Earl's Perform-O-Flex stainless steel braided hose is comprised of a section of rubber tubing interwoven with a steel sheath and covered with yet another steel sheath. In order to mate properly with its corresponding hose end, such hoses must be cut sharp and clean, like this.

| Earl's Perform-O-Flex stainless steel braided hose is comprised of a section of rubber tubing interwoven with a steel sheath and covered with yet another steel sheath. In order to mate properly with its corresponding hose end, such hoses must be cut sharp and clean, like this.

Practical Applications: Fuel Lines

Sizing fuel system hoses correctly pays large dividends. Honda's fuel injected systems are pressurized at approximately 60-70 psi from the factory. In certain aftermarket applications, fuel pressure is often increased in order to deliver more fuel through the injectors' fixed openings. This pressure is largely dependent upon the fuel pump's ability to move liquid, which is dependent upon the feed line's ability to carry fuel. Therefore, the feed line's size is determined by the amount of volume the fuel pump needs in order to produce the required pressure on its outlet side. This means that feeding a fuel pump with -6 or smaller supply line won't be enough to pressurize a -6 line to the fuel rail. This explains why the inlet side of a fuel pump is always larger than the outlet side. Subsequently, for a typical Honda, supplying a fuel pump with -8 steel braided hose, or its non-reinforced rubber equivalent, and exiting with a -6 line will provide enough capacity to pump fuel acceptable for most street applications. Higher horsepower applications should bump sizing up to -10 and -8, respectively.

Using The Correct Hose Ends...Correctly

Hose ends are offered in many shapes and sizes. Each serves a special purpose. For example, there are tube-style and forged-style hose ends. Tube hose ends are less expensive than forged ones but are weaker in terms of extreme vibration and leverage. Forged hose-ends are stronger but tend to cavitate fluid at their bends, reducing the flow path's size, especially in 90-degree pieces. It's customary to use tube hose ends for oil due to the fluid's lower viscosity, and forged hose ends with fuel to accommodate the higher pressure. Forged hose ends also feature a lower profile, making them desirable for tight spaces.

Some hose ends swivel, even once assembled, like Earl's Swivel Seal pieces, making orientation, aka clocking, possible after assembly. Such hose ends are more expensive but allow for precise fitment. Manufacturers like Earl's make a variety of hose ends in different angles for many types of hose depending on the application. Using the proper shaped hose end can eliminate the need to bend the hose itself.

| Earl's Speed-Flex stainless steel braided hose is similar to Perform-O-Flex but uses an extruded section of Teflon instead of rubber. Speed-Flex is not as flexible as rubber-based, steel braided hose but is conducive to extremely high pressures, like those exerted by hydraulic systems. Speed-Flex hose assembly is different than that of other steel braided hoses because it uses a non-reusable crush olive to seal.

| Earl's Speed-Flex stainless steel braided hose is similar to Perform-O-Flex but uses an extruded section of Teflon instead of rubber. Speed-Flex is not as flexible as rubber-based, steel braided hose but is conducive to extremely high pressures, like those exerted by hydraulic systems. Speed-Flex hose assembly is different than that of other steel braided hoses because it uses a non-reusable crush olive to seal.

Engineers have developed various ways to connect hose ends including swaging and crimping. Both have their limitations. Only straight hose ends can be swaged and crimping leaves a nasty finish. Both require expensive hydraulic equipment. Assembling a hose end by hand and screwing it onto the hose is popular since the tooling is minimal and can be done by just about anyone. Both Earl's Auto-Fit and Swivel-Seal hose ends allow for this. Stainless hose should be cut with a toothless blade chop saw. Hacksaws increase the probability of a leaky assembly. Using cutters is even worse and can damage the hose, resulting in more leaks. Hose end assembly is relatively easy as long as the threads are lubricated. AN components should never be assembled dry since the anodizing increases the chances of seizure. The hose end's or socket's threads can easily strip in such cases. The coarse thread of the AN nut is not as sensitive to stripping but may never come apart once tightened without anti-seize.

Although, in practical application, most any steel braided hose has a high pressure rating, its hose ends dictate its true pressure-handling capabilities. The same goes for using the wrong adapter. The weakest part of any hose assembly is the connection between the hose and its hose end. Blown-off hose ends are far more common than exploding hoses. Even when the ends are engineered specifically for the hose, failure is a legitimate concern.

| Hardware store brass fittings can be tempting. They're cheap, easy to find and appear to be compatible with AN components. They aren't. Automotive-grade AN fittings feature 37-degree flares while home improvement fittings have 45-degree flares. They simply don't mate together properly and will ultimately leak.

| Hardware store brass fittings can be tempting. They're cheap, easy to find and appear to be compatible with AN components. They aren't. Automotive-grade AN fittings feature 37-degree flares while home improvement fittings have 45-degree flares. They simply don't mate together properly and will ultimately leak.

BSPT VS. NPT

Although proper hose and hose end selection is critical, in most cases the hose never gets a chance to fail since adapters with ill-conceived sealing surfaces and improperly sized thread pitches are used. One such consistent mistake is the method in which LS-VTEC, turbocharger feed lines and oil pressure gauge sending units are sourced from the block's factory oil pressure sensor location. This may seem like a 1/8-inch NPT opening but it isn't. No, Honda uses 1/8-inch BSPT threads here, which feature the same NPT thread pitch but without the taper inherent of NPT threads. BSPT fittings seal with washers and O-rings at their mating surfaces while NPT threads seal against tapered threads. It's possible to thread like-sized NPT fittings into BSPT ports but the seal will only occur at the expense of destroying the weaker component's outermost threads, which is in Honda's case, the softer aluminum block.

AN VS. NPT

NPT threads are tapered so as to seal using their threads. They are not compatible with AN threads, which is why Earl's offers so many NPT to AN adapter fittings. This is also why Teflon tape or paste is used on the threads themselves. However, using Teflon tape, paste or any other type of sealant on straight threads with O-ring seals or AN flare seals is not an insurance policy against leakage but, rather, the cause of leaks. Never use any type of sealant when working with 37-degree AN flare fittings. AN hose ends and adapters will always seal on the flare, NPT threads need sealant while straight threaded ports will always seal on O-rings. Enough said.

| Automotive Plumbing - The Art Of Fluid Dynamics: Part One Of Two - Wrenchin'

| Automotive Plumbing - The Art Of Fluid Dynamics: Part One Of Two - Wrenchin'

AN VS. Everything Else

The main difference between automotive grade AN style fittings and Home Depot brass are its sealing surfaces. AN pieces rely on a 37-degree flare while those designed for home improvement feature a 45-degree flare. The difference may not sound like much but those 8 degrees can be the difference between whether your fuel line leaks or not. A 37-degree flare pressed against a 45-degree seat results in a single ring of sealing area by cutting into the surface instead of sealing across the flare's entire face. Unfortunately, Internet hearsay has paved the way for much of the misinformation surrounding many Honda-specific plumbing configurations, including the ability to combine water heater brass fittings with steel braided hose and AN hose ends. While such brass fittings may appear to work, they don't. In an effort to stop the leaking, many wrap such fitting's straight threads using Teflon tape, which defeats the purpose of the flare sealing design, shifting sealing duties onto the tape-a good idea if you like fireworks.

Next Time

Theory will only get you so far and, frankly, the applications in which high-performance plumbing may be applied to your Honda are practically limitless. Next month we'll review several real-world applications with instructions on configuring your own turbocharger feed and drain assemblies, LS-VTEC setups, brake and clutch lines, fuel lines and more.