| 2006 Honda Civic Si - New Dog Likes Old Tricks - :Wrenchin

| 2006 Honda Civic Si - New Dog Likes Old Tricks - :Wrenchin

Honda's New Civic Si Goes Old School And Nets 260 whpIt's hard to believe that the Civic Si has been on the streets for almost two years. Though the K20Z3 isn't a great deal different than the A2 or Z1 K20s that came before it, there are some improvements and twists that have kept us from getting our hands on significantly tuned-up Si's.

Maybe the biggest stumbling block is that Honda has switched engine management in a big way. There is now a mass airflow sensor on the K20Z3. In the past, Honda had always used speed density for computing airflow, but ever-tightening emissions standards forced Honda to make the switch.

| A set of Eagle H beam rods and Supertech 12:1 compression pistons are set to be put into place.

| A set of Eagle H beam rods and Supertech 12:1 compression pistons are set to be put into place.

According to Doug McMillan of Hondata, "The primary sensor for deciding the amount of fuel is now the mass airflow sensor. At part throttle and low engine speeds, it's highly accurate at measuring the actual grams per minute of airflow into the engine. And yes, you're right, it was probably done for emissions reasons. Many other companies already use mass airflow."

What that means to us tuners is that an ECU from an RSX modified by Hondata and called K-Pro, won't work in a '06 and up Civic Si. That makes it a bit harder to just throw parts at it and get good results, but that didn't stop car owner James Norman from trying.

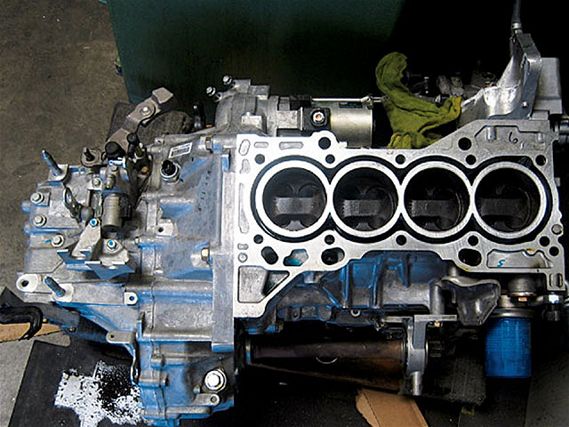

| This is how James Norman's '06 Civic Si started its journey at the Hytech Exhaust shop in Irvine, Calif. Pretty much stock except for the warm air intake.

| This is how James Norman's '06 Civic Si started its journey at the Hytech Exhaust shop in Irvine, Calif. Pretty much stock except for the warm air intake.

James had worked with HyTech Exhaust in Irvine, Calif., previously and also had a hookup with Supertech, so off the car went to HyTech Exhaust. John Grudynski, the owner there, quickly removed the engine and tore it all down.

First up was the installation of the Eagle connecting rods. Attached to the rods is a set of Supertech 12:1 forged pistons that were hand-finished by HyTech to remove the sharp contours of the pistons dome. This helps with the flame travel across the dome and with cylinder filling. This compression ratio meant James would have to run some higher octane gas like half 100, half 91 octane, but he was cool with it.

| The entire engine assembly was yanked and stripped of all of its components.

| The entire engine assembly was yanked and stripped of all of its components.

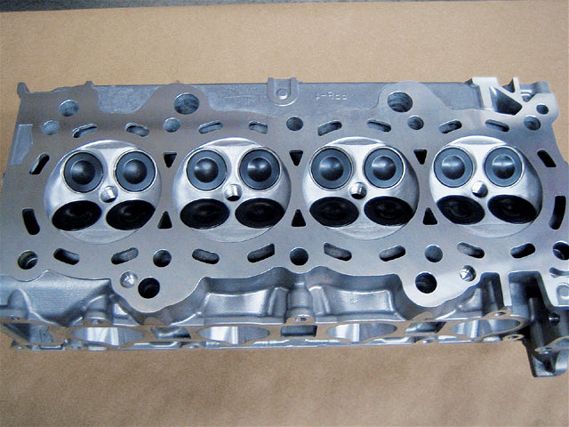

The head was shipped off to Endyn for some clean up and a simple valve job. When the head returned, it was filled with a complete Supertech valvetrain. Only the early '02 RSX Type-S and the ITR have dual valvesprings, so to get a 9,000rpm limit moving Supertech dual springs with titanium retainers was a requirement. Standard size valves were also installed.

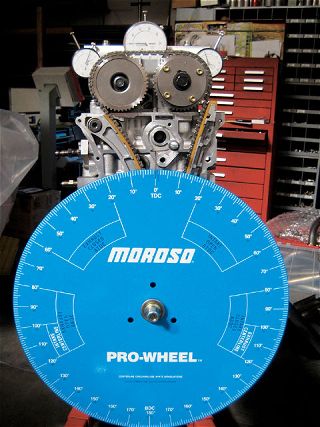

The head was finally ready for a pair of HyTech's Spec 1 cams. Initially, the Spec 2 cams were installed but after checking the clearances, Grudynski found the Spec 2's duration combined with the iVTEC cam timing he wanted to use in the midrange would cause a cam-piston collision because there was not enough valve relief in the prototype Supertech pistons (production pistons will have deeper reliefs). When building a piston-cam setup for the first time, this is a critical step and can't be skipped or you'll truly pay for it. A step back to the Spec 1 cams (which are meant for stock valve reliefs) and all was clear.

| A quick bore cleanup and in go the pistons and rods. Awesome to see a dome that big.

| A quick bore cleanup and in go the pistons and rods. Awesome to see a dome that big.

So now the head was complete with the Supertech/Hytech combo and with the new rods and pistons, things were looking good for the block. But James wasn't going to quarter-mile the car primarily, he was going to road race and high-speed race it-specifically the Silver State Classic. The SSC is a top speed run held in Nevada twice a year. It's essentially a one state Cannonball Run.

The ITR spec racing class in Japan has already proved that it's fairly easy to oil starve a K20 under high G loads. To help, some guys use an Accusump, others put in an S2000 oil pump and others a dry sump system. But for over a year now, HyTech has been supplying the oil pans for the Grand Am Cup cars. HyTech's special oil pan baffle setup, combined with a modified pump, keeps oil all over these engines.

| The head went off to Endyn for a quick valve job and then back to HyTech to be prepped for 9,000 rpm.

| The head went off to Endyn for a quick valve job and then back to HyTech to be prepped for 9,000 rpm.

Since the new K20Z3 engine has balance shafts, a good deal of space needed for baffles is already occupied. To get it to all fit, Grudynski cuts down the block girdle section where the oil pump bolts down and also takes some material off the oil pump from a K20A2 or Z1, planting it on the Z3 engine. You can't use the Z3 oil pump with these modifications.

With all the mods complete, Grudynski put the engine back in the Si and went to work on attaching one of his handmade custom headers. This is HyTech's claim to fame. Made from stainless steel and his patented reversion chambers, HyTech headers are like no other on the market. To complete the exhaust is a full 3-inch setup, including a twin-loop style muffler that actually quiets things with hardly any restriction.

| Anytime you have custom cams and high-compression pistons, it's a good idea to not only degree the cams, but also to check valve-to-piston clearances. The Spec 2 cam Hytech wanted to use was a little too much for the Supertech pistons and they may have hit. Without checking, it would have been big trouble.

| Anytime you have custom cams and high-compression pistons, it's a good idea to not only degree the cams, but also to check valve-to-piston clearances. The Spec 2 cam Hytech wanted to use was a little too much for the Supertech pistons and they may have hit. Without checking, it would have been big trouble.

The final part of the hardware puzzle is the intake manifold, which is the stock unit with an added twist. A '06 TSX 64mm throttle body was bolted on in place of the 60mm stock unit. Since they're both drive-by-wire, it was simple a matter of opening up the RBC intake just a bit.

Obviously all this old school hardware is incomplete without a trip to the dyno and the IT department. As part of the Spec product packages (typically header, exhaust, cams and intake), HyTech has created reflashes for the stock ECU. They're custom tailored to HyTech's products and only available through HyTech.

On the Dynapack at Church Automotive in Wilmington, Calif., this re-flash enabled James' Si to put down an incredible 260 whp in third gear. The Si proved to be a slightly underrated 197 hp and a baseline of a completely stock unit on the same dyno showed 193 whp. That means this HyTech combo gained an amazing 67 whp. Definitely power you can feel on the road

All that added power certainly didn't come cheap and the car is no longer emissions legal, but in an already lightened race car, the Silver State Classic will go by even faster.

Cams - $900

Springs/Retainers - $400

Header - $1,300

Exhaust - $1,150

Pistons - $600

Rods - $400