| Auto Meter's Data Logger Racing Computer - Tuning Tech

| Auto Meter's Data Logger Racing Computer - Tuning Tech

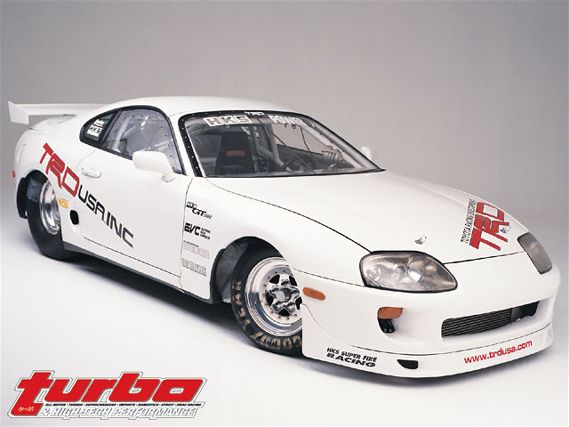

We were turned on to this data logging system when Craig Paisley credited its use with a .18-second improvement in the Paisley Racing/TRD-sponsored Supra. The internally stock-engined Supra improved from 8.72 to 8.54 when the Paisley Racing crew used the Auto Meter computer to determine the engine was on the rev-limiter at the end of the run and it was running low EGTs, which meant the fuel curve could be tuned leaner. This leaner, meaner curve and harnessing the 2JZ-GTE's full power netted the big number, making the Supra the world's quickest JZA80.

The heart of the Auto Meter system is the 17-channel Data Logger computer. The 17 channels encompass three rpm outputs, one pressure output, one accelerometer output, eight EGT outputs and four auxiliary outputs that can be configured to the user's preference. Auto Meter set-up the product line to allow the end user to plug in only the sensors he needs. This cuts the cost of getting started and allows for future expansion. There is a myriad of sensors that can be configured into the system. These sensors are outlined in the accompanying chart. Measurable parameters include; engine rpm, driveshaft rpm, input shaft rpm, exhaust gas temperature, pressure, temperature, voltage, linear travel, rotary travel and vacuum. An accelerometer can also be used in data acquisition.

By running engine speed, driveshaft speed and an accelerometer slippage can be determined and its cause identified-wheel slippage or clutch slippage. Exhaust gas temperatures can be tracked with two, four or eight sensors depending on the engine in question. There are six different pressure sensors each with its own rating, from 25 psi to 2000 psi. These sensors are utilized based on what pressure one wishes to monitor, e.g. fuel pressure, oil pressure, boost, nitrous bottle pressure and so on. The 25-psi sensor can be used for boost (up to 25 psi, of course) or for fuel pressure before and after the regulator on carbureted applications. A possible use for the 100-psi sensor is fuel pressure on EFI engines. The 200-, 500-, 1000-psi sensors could be used for fuel pressure on a Top Fueler, while a 2000-psi sensor can be used to track nitrous bottle pressure from launch to let-off.

There are a number of other useful sensors in the Auto Meter arsenal. The voltage reducer tracks voltage outputs of sensors with a 0- to 5-volt output like a TPS sensor or MAP sensor. The vacuum sensor measures vacuum in the crankcase and can signal when too much pressure gets by the rings, which means that a cylinder is on its way out. The resulting loss of compression translates into less power. The linear travel sensor can be used for clutch linkage and shock travel and the rotary travel sensor can be used for throttle position and shock travel, amongst other things.

Along with the aforementioned clutch slip set-up, the Auto Meter Data Logger computer can be configured to track fuel pressure vs. rpm during a run. The user can also see how much the fuel pressure drops at launch and how long it takes the pump to catch up with fuel demands during a quarter-mile run or a hard blast on the street. This scenario could indicate the need for a bigger pump, higher flowing regulator or even the need for larger diameter fuel lines. The Data Logger could show that all is well with little drop in pressure during the run.

Generating raw data is one thing, translating that data into information that can be used to improve performance is another issue all together. It all comes down to software. The software formats the information and allows the user to view it in a manner that promotes tuning. One of the keys to making software work in the real world is its operating system. If a system requires programmer's language, it is greatly reducing its potential. The more user friendly the OS, the more user friendly the whole system will be. Auto Meter's Data-Facts Pro(tm) software is based on Windows 3.1, 95 and 98; it doesn't get any friendlier than this. The Data Facts Pro software produces the data in graph format and allows the user to scroll through a run, via time. At each position on the graph, data from all of the sensors or any combination of sensors can be compared. The graph can be zoomed in, condensing time and offering higher resolution to facilitate fine adjustments. The software allows data to be read down to .01 second intervals.

Another impressive aspect of the Data-Facts Pro software is the Racer Log Book. This allows the user to store runs and call them up at will. Using the Racer Log Book's search engine function, runs can be retrieved based upon 14 different parameters. For instance, all the runs under a certain e.t. can be compared. Furthermore, runs with a certain mph, from the same track, from the same altitude or from the same day can also be compared. Examples of the data logging graphs and Log Book program can be seen in the accompanying screen captures.

Craig is not the only import drag racer to use the system; Abel Ibarra has one in his Pro Class RX-7. Rumor has it that Braman Motorsports will be the first front-drive vehicle to run the system. The company's 9-second Honda (April 2000, Turbo) should really benefit from knowing exactly where, during a run, wheelspin occurs. Auto Meter also offers a 34-channel system that includes the same outputs as the 17-channel unit, except it provides 16 auxiliary outputs instead of four, and includes a battery voltage output not available with the 17-channel set-up.

Auto Meter plans to add a fuel flow sensor to its array of sensors in 2000. Craig Paisley's Supra is an excellent example of how useful this tuning tool can be. We see it being most beneficial on cars running modified stock ECUs or stand-alone engine management systems with limited or no data-logging capabilities and almost any traction challenged car-race or street. It's hard to argue against a technology that provides such dramatic increases in performance in such little tuning time.

AUTO METER DATA LOGGER HIGHLIGHTS Channels: 17 Sampling Rate: 100 times per second Downloading: Computer or printer Software: Data-Facts Pro, Windows-Based PC Logbook: Store and retrieve data for comparisonData Acquisition SensorsEngine RPMDriveshaft RPMInput Shaft RPMExhaust Gas Temperature (3)Pressure (6)AccelerometerTemperatureVoltage ReducerLinear Travel Rotary TravelVacuum( ) = number of different configurations