| Variable Valve Timing: What Is It? Who Needs It?

| Variable Valve Timing: What Is It? Who Needs It? The language of import performance can be strange. Sometimes it's a verbal stew of numbers and letters--RX-8, NSX, and MR2, for example--that seem randomly tossed together. At other times it adopts words, such as Civic and Skyline, that originally had no relation to the automotive world at all. Weirder still is when companies just make up stuff, like Sentra and Celica, and hope that names like those will make you want to own one of these vehicles--even if you have no clue of what it means. (The import world isn't alone in this. Who ever thought Citation was a good name for a car, anyway?)

The jargon goes well beyond just names. Car specs are full of abbreviations that may or may not have any meaning at first glance. And sometimes we get so used to seeing those abbreviations that we may think we know what they mean, but in reality, we don't. So we make stuff up. Sure, we could describe what DOHC means, or TDC. But what about VTEC, that engineering feat that's been around for more than a decade and has crossed ver from the race-bred NSX to the bread-and-butter Civic? Do you know exactly what it is, how it works, or what makes it different from the new i-VTEC? What about the other V-word systems, such as Toyota's VVT-i, Nissan's CVTC, or Mitsubishi's MIVEC?

All of those letter scrambles are part of the wonderful world of variable valvetrain systems, an awesome technology that is crossing over from high-performance cars to the more mainstream sedans and even--shudder--SUVs. We'll explain what these systems are and how they work so you can toss the terminology around, know exactly what it means, and impress silicone-enhanced females and their "curious" girlfriends. After all, that's what it's all about, right?

Valvetrain Basics

Before you can appreciate the benefits of variable valvetrain technology, you have to understand the limitations of traditional valvetrain systems. So let's go back to Auto Shop 101 for a bit.

Designing a camshaft to properly time valve operation is a delicate act. The engines in our cars operate at anywhere from around 800 rpm at idle to, well, you name it on the top end. Even at a relatively moderate 3,000 rpm, the valves are opening and closing two dozen times per second. That doesn't allow a lot of time for air to flow in and out of the cylinders.

The characteristics of a high-performance engine compound the problem. It operates at higher engine speeds than a "normal" engine does, so the valvetrain's opening and closing events are happening even more quickly. Yet at the same time the performance engine requires more air and fuel to create more power. So the typical high-performance camshaft has lobe profiles that provide more valve lift, allowing a greater volume of air to pass through the port. The lobe profiles also open the valves for a longer period (called duration), giving the air more time to pass into or out of the chamber.

But that high-lift/long-duration cam won't work in a normal engine. It would hold the valves open too long for low and normal operating speeds. On the intake side, for example, if the valve stayed open too far into the compression stroke, the piston would push fresh air and fuel back out the intake port. Or if the exhaust valve stayed open into the start of the intake stroke, waste gases could be pulled back into the cylinder and dilute the fresh charge. At racing speeds, that sort of valve timing and overlap works to efficiently move air through the cylinders. But have you ever noticed that racing engines don't idle worth a damn? That's cam timing, folks.

Conversely, the relatively low valve lift and short duration that work so well in a normal engine would strangle the high-power motor. Maybe not at idle or initial throttle tip-in but certainly at high revs where it needs to work.

And there's the limitation of the traditional cam and valve setup. Cam timing, since it's governed by the shape of the cam lobes and the position of the cam relative to crankshaft rotation, is fixed. The cam works most efficiently at one engine speed. You can vary the timing of the events by advancing or retarding the camshaft, which will improve bottom- or top-end power, depending on which way you move the cam. But you can't have it both ways. Getting power and performance at low and high revs is impossible--unless you could somehow vary the cam's timing and lift based on engine speed...

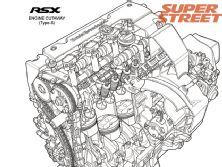

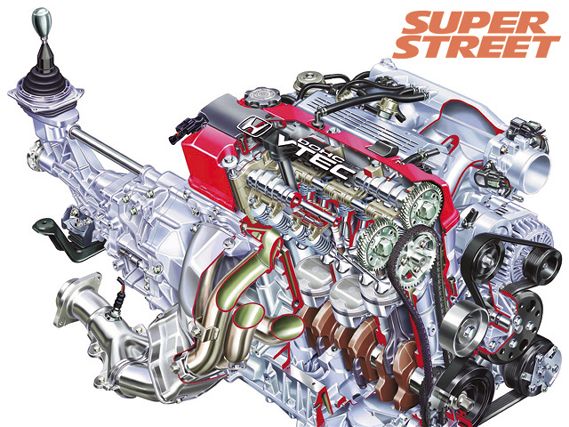

Honda/Acura VTEC

VTEC is Honda/Acura-speak for Variable Valve Timing and Lift Electronic control. (VVTALEC just isn't animal enough, is it?) First introduced aboard the groundbreaking NSX in 1991, VTEC is now available across the Honda/Acura product line, right down to the gas/electric Civic Hybrid. VTEC has evolved to suit those various engine applications, but its basics have remained the same.

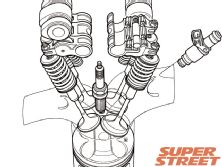

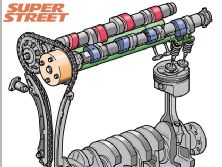

The heart of the VTEC system is the design of the camshaft, with three lobes for each pair of intake and exhaust valves, plus the corresponding rocker arms that actuate the valves. At low- to midrange engine speeds, the valves are opened and closed by the rocker arms following the two outboard lobes. These outboard lobes have been ground to provide relatively low lift and short duration. Once a certain engine-speed threshold is crossed (varying from around 6,000 rpm in the NSX, RSX, and S2000 to 5,600 rpm in the Prelude), the VTEC computer sends a signal to a valve that uses engine oil to pressurize small pistons in the rocker arms. This locks the two outboard rocker arms to the center arm, which is aligned with a higher-lift, longer-duration cam lobe. The valves now open farther and stay open longer to feed the engine the increased air and fuel it needs for high-rpm, high-horsepower operation.

In the 10-plus years since VTEC's introduction, the corporation has developed some interesting variations on the theme. The current Civic Si and 160hp RSX engines are fitted with a simplified rocker system, with two arms that adjust the valve timing on the intake side of the engine only. Below 2,200 rpm, incoming air moves primarily through only one intake valve, giving the charge a strong swirl that improves low-speed combustion. Above 2,200 rpm, the second rocker arm engages the first, so that both intake valves open for the same lift and duration, which greatly increases the amount of air for the engine to burn. The 200hp motor in the RSX Type-S uses the traditional three-arm rocker setup on both the intake and exhaust valves.

The Civic Si and both RSX models also share the new "intelligent" VTEC system, called i-VTEC. The "i" is really a less cumbersome way for Honda to say it has added Variable Timing Control (VTC) to VTEC. VTC is similar to BMW's VANOS system, which adjusts the phasing of the intake camshaft to continuously match the engine's air and fuel needs. Here's how it works: The VTC actuator monitors a number of engine inputs--cam position, ignition timing, throttle position, and more--and then sends pressurized oil to chambers inside the cam's drive sprocket to advance or retard the cam's position relative to the crankshaft. So when you're sitting at a stoplight, for example, the cam is almost fully retarded to provide a smoother idle and reduce NOx emissions. Crack open the throttle, and the cam will advance to open the intake valve sooner and build in more valve overlap, which improves midrange responsiveness.Honda plans to have added this "i" technology to all of its four-cylinder engines by the time you read this., but does this mean Type-S cars for everyone? Hardly. While the VTC system does help the engine make power, that's a side benefit to the corporation's real target: efficiency. VTC reduces emissions and improves fuel economy to help Honda meet the ever-stricter engine regulations here and in Japan.

Toyota VVT-i

Toyota came somewhat late to this party; its Variable Valve Timing with Intelligence (VVT-i) system was introduced for the V-8, V-6, and I-6 engines in '98-model-year Lexus LS400s, SCs, and GSs. But the company is making up for lost time, as VVT-i is now on virtually every Toyota and Lexus car in the line.

VVT-i works much like Honda's VTC system. An engine control unit monitors various inputs (including engine speed, airflow, coolant temperature, and so on). Using oil pressure to actuate a camshaft timing pulley, it then advances or retards the intake camshaft to suit the engine's operating needs.

Since the introduction back in 1997, Toyota has developed a two-step, rpm-related variation of VVT-i called VVTL-i, which stands for Variable Valve Timing and Lift with Intelligence. Found aboard the 1.8L, 180hp engine in Toyota's Celica GT-S, the VVTL-i combines the continuously variable cam phasing with new, dual-lobe camshafts for both the intake and exhaust valves. At engine speeds below 6,000 rpm, a set of rocker arms follows a set of low-lift, short-duration lobes. At six grand, a pin under the rocker arms pushes them so they engage the second lobe set, which has been ground to make significantly higher lift. As with the VTEC system, the taller lift is better matched to the air-gulping needs of an engine spinning between 6,000 rpm and its 7,800-rpm redline.

Nissan CVTC

Nissan's VQ V-6 engines, which began life in the Maxima and are now found in the new Altima, the Infiniti G35, and the 350Z, feature a valvetrain with Continuous Variable Timing Control (CVTC). Similar to the VTC and VVT-i setups already discussed, CVTC is a cam-phasing system. A vane, housed within the cam-drive sprocket, rotates to advance or retard the intake camshaft's timing to maximize the engine's efficiency and power output based on engine and driving-condition information it gets from the engine's control monitor. Advancing the cam timing boosts low- to midrange torque, while retarding the timing improves high-rpm performance.

Unlike the other technologies, though, CVTC doesn't have a corresponding system to alter the valves' lift or duration. So like the hot rod cam that is advanced or retarded during an engine buildup, CVTC doesn't change the character of the valve-opening event, just its timing. But unlike old-school hot rod cams, CVTC can move both ways, at will, to affect power throughout the rev range.

Mitsubishi MIVEC

The Mitsubishi Innovative Valve Timing and Lift Electronic Control (MIVEC) system went into production in 1993 and was used on several of Mitsu's home-market vehicles from the early to mid-'90s. Applications ranged from 1.6L four-bangers in the Mirage Cyborg, Mirage Asti, and Lancer to a 2.0L V-6 for the FTO (an Eclipse-like coupe also known by its full name, Fresh Touring Origination) and even a 3.0L V-6 version for the high-line Diamante. MIVEC is old tech now, though, as Mitsu has phased it out in favor of other engine-efficiency models, such as direct gasoline injection.

So why are we talking about mid-'90s Japanese technology? These were pretty respectable machines in their day. The 1.6L MIVEC motor peaked at nearly 175 hp, which at the time was the "highest unit power output for a non-supercharged production engine anywhere in the world." The other two motors weren't bad, either--the 2.0L made just shy of 200 hp, and the 3.0L churned out a tick over 265 horses. In box-stock form. No wonder there are rabid MIVEC fans all over the Internet, telling tales of MIVEC engine swaps and 7-second 0- to 100-mph sprints. As with VTEC, the MIVEC system used camshafts with low- and high-speed lobes, dual rocker arms, and a hydraulically controlled lever that would engage either rocker depending on engine speed. The threshold for MIVEC was 5,000 rpm. Below that the low-speed lobes actuated the low-speed rockers and the car felt like any other. At five grand, though, the lever engaged the high-speed rockers, allowing the high-speed lobes to use their higher lift and longer duration, and the motor would scream right up to its 8,000-rpm redline.

Yet peak power was only part of the MIVEC story. For those who were seeking optimal fuel economy (an important consideration in Japan), a second version of MIVEC came with a modulated-displacement (MD) mode. At low engine loads (in urban driving conditions, for example), the lever connecting the high- and low-speed rockers in cylinders 1 and 4 would disengage, closing the valves and turning the four-banger into a two-banger. Not the most exciting thing for an engine to do, but testing by Mitsubishi showed that at a steady 60 km/h, the 1.6L MD-mode MIVEC engine delivered 26 km/L (or 61 mpg at around 37 mph). Keep in mind that the MD mode didn't negate any of the top-end power available to the MIVEC motor from its high-lift cam lobes. So this one engine could go from gas sipper to pocket rocket with a simple stab of the gas pedal.