Since we last visited the project, Autowave, in Huntington Beach, Calif., had a chance to get the Type S K20A2 cylinder head freshened and mated to a K24 block. Remember that the 2.4-liter bottom end was outfitted with Pauter rods and slightly domed CP slugs, which should raise compression to 11.5:1, the same ratio as a JDM Integra Type R engine. Owner of the motor and recipient EM2 Civic chassis, Troy Sullivan, took care of dropping in the power unit, and has also equipped the hybrid with an ITR intake manifold, a Comptech header, and a custom exhaust.

| Honda K20A2/K24 Camshaft Install - 2.4 Liters Untamed

| Honda K20A2/K24 Camshaft Install - 2.4 Liters Untamed A few preliminary comments should be made about sourcing and working with the Type-S head for those planning on doing a similar swap. The RSX-S is still the only North American source for A2 heads, so you may have to broaden your search to include JDM engines. (As far as we know, the jury is still out on the effectiveness of K20Z heads from the '05-and-up S for this procedure, although we can't imagine why they wouldn't work.)

In the Japanese market, the top ends we're interested in sit on K20A's found in Civic-R's and ITRs. You can get one with a factory LSD-equipped gearbox and ECU for between $4,000 and $6,000. The K20A head you'll wind up with is arguably better than the A2, having longer duration intake and exhaust cams, but don't get the K20A or A2 confused with the K20A3, which is the EP3 Si/base-model RSX engine.

On the front of the engine, Autowave's Mike LaPier utilizes the K24 timing chain, auto-tensioner, guides, and chain cover because of the taller deck height. The K20A2 crank pulley is smaller than the K24's to keep the accessory rpm down on the higher revving engine, so that's sort of like a free underdrive pulley.

| Since the crank pulley is going to be removed for access to the timing chain auto-tensioner, the drive belt for the alternator and water pump has to come off. LaPier does this by moving the tensioner pulley toward the rear of the engine compartment with a boxed end wrench and relieving tension in the belt. The belt should slide right off.

| Since the crank pulley is going to be removed for access to the timing chain auto-tensioner, the drive belt for the alternator and water pump has to come off. LaPier does this by moving the tensioner pulley toward the rear of the engine compartment with a boxed end wrench and relieving tension in the belt. The belt should slide right off. On top, LaPier uses the head gasket from the K24, which is sized for the larger bore diameter. The head can be bolted on with either set of head bolts. It's the builder's choice to reuse the head bolts or the gasket, but if you're in doubt, or if you have plans for forced induction, you should probably buy new parts. LaPier notes the head bolt torquing procedure is different between used and new head bolts, so you should consult a Helm's manual for details.

Once the head is torqued down, LaPier installs the casting that holds the rockers, followed by the cams and cam caps. He checks off the timing chain, tensioner and guide, and replaces the crank angle sensor wheel, making sure to put it on in the right direction. Then he covers it up with the K24 chain cover and Hondabond to keep the oil in.

| Honda K20A2/K24 Camshaft Install - 2.4 Liters Untamed

| Honda K20A2/K24 Camshaft Install - 2.4 Liters Untamed Finally, because of the added deck height, the K20A2 intake manifold support bracket that stretches to the block doesn't quite reach. We've known people to fabricate a 19.7mm tall spacer to take up the slack, but you can do something similar on the cheap with a stack of washers.

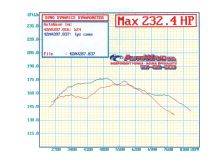

This last episode in the saga finds LaPier swapping out the factory camshafts to replace them with versions from Intrinsic Performance Solutions. LaPier will walk us through the process of swapping sticks, which is a little like working on a B, a little like working on an F20/F22. LaPier concludes with a dyno tuning session wherein he makes the Franken-motor respectable through the use of a Hondata K-Pro programmable ECU.

Intrinsic Performance Solutions

In many ways, IPS was born out of protest. Two years ago, Ron Acevedo, the company's 31-year-old founder, president and CEO, was just another enthusiast looking to maximize output from the K-series plant in his 2002 RSX-S. When the engine's upgrade arc called for new camshafts, he looked to the aftermarket, only to discover what it had to offer was unimpressive and dissatisfying.

He saw that many of the industry's companies do little to educate their consumers, instead relying on customer ignorance to preserve high margins and sustain bottom lines. Most of the products he's tried from the aftermarket lack true engineering.

In his personal crusade for tuner parts, he also encountered several cam manufacturers that were impossibly slow in getting product to market. These frustrations ultimately compelled Acevedo to begin work on his own bumpsticks, and shortly thereafter IPS was launched.

Officially a business since November 2004, the Torrance, Calif.,-based outfit is essentially just one guy, Acevedo, but there is very much a team effort component to the company's R&D operations. Acevedo says he could not have accomplished all that he has without those who paved the way for him, and cites many of the industry's leading manufacturers and shops as sustainers. These include Hondata, Prototype Racing, Port Flow Designs, Alaniz Technologies, R&D Dyno, Church Automotive, and Erick's Racing.

While he consorts with decidedly Honda-friendly types, Acevedo himself is something of an unlikely champion for the scene. The former liberal studies student and IT professional cut his enthusiast teeth on Nissans, wrenching on L-series in 510s and later an SR20 in an S13 that was featured in Turbo magazine. Really, he's only been into Hondas since he bought his own Type-S in '02, and has since sold it to help launch Intrinsic. He assures us it will resurface soon, though, as the new owner, Hondata, promises to drop a supercharged TSX motor into the DC5.

The sport compact cam biz is a competitive one, so it begs the question, Why start a cam company? Acevedo calls it a labor of love, explaining his only motivations are a desire to make more power and have fun with cars. He's clearly not in it for the money, at least in the short term, because he believes IPS will be operating in the red for at least three to four production runs, based on its overhead. This is definitely a long-term project, so he's focusing on what may lie ahead, such as intellectual property thievery.

"My engineers have told me we have to stay one step ahead of them," details Acevedo. "As soon as they start pushing out knockoffs-and they will-we've got something for them."

Acevedo is very proud of the quality he engineers into each camshaft, and IPS's Web site, www.intrinsicperformance.com, does a fantastic job at explaining the different production methods the company uses. Indeed, the IPS peeps are very open with their research, and they confess they can't prevent people from copying their cams.

But they also know there's more to improving volumetric efficiency through cam profile design than just grinding cams using figures from a Web page. As the site indicates, successful cam profile design has an intrinsic relationship with the spring that controls valve motion.

The design philosophy has resulted in the development of six different IPS camshafts for heads on Honda's K20A(2) engine platform, three sticks for naturally aspirated engines and three for forced induction apps. Right now, Acevedo's K2 all-motor cam is generating the most buzz-a maximum-performance "street" bumpstick good for up to 300 hp. He indicates the K2 is relatively flexible, which is why we're able to run it in our poor man's TSX motor project.

The IPS N/A series also includes the KME (ME stands for "maximum effort"), a cam that preserves 50 degrees of variable timing control but is designed for larger displacement, race-oriented powerplants; and the K10, a next-gen. stick engineered for 10,000-rpm applications and meant for pro drag race engines. Intrinsic's forced-induction lineup consists of the KSC for blower setups, and the KT1 and KT2, cams for different stages of turbo motors. The T1, which is also getting notice lately for its power potential, is geared toward the street/strip and can work to 9000 rpm with the proper turbo sizing; the T2 is a pro drag turbo cam for big turbos and 10,000 revolutions.

| The chain tensioner is returned to its home in the chain cover, LaPier using a pushpin to hold up the lever that compresses the mechanism. Once it's secured in place, the pin can come out and the shaft should apply tension.

| The chain tensioner is returned to its home in the chain cover, LaPier using a pushpin to hold up the lever that compresses the mechanism. Once it's secured in place, the pin can come out and the shaft should apply tension. IPS has done a brisk business in its first year, shipping 80 K2 cams from its first production run of 100, bringing its turbo cams to market, and taking pre-orders for the KSC from folks who are basing their decision on recently published testing results.

Still in the R&D phase is the remainder of the all-motor camshafts, and Acevedo hopes to expand his K-specific focus to include cams for S2000 F-series motors and NSX C-series motors. He's also looking further down the line at perhaps coming up with profiles for the WRX STi, but when asked about whether or not he has any interest in developing something for Honda's B series, he is clearly cool on the prospect.

| A fresh valve cover gasket is pressed into the groove in the cover, and Hondabond is applied to strategic points for preserving a good seal.

| A fresh valve cover gasket is pressed into the groove in the cover, and Hondabond is applied to strategic points for preserving a good seal. "It's really a crowded market, and we may revisit [the B series] after we knock out the high-profile stuff, but the B series has pretty much had its day."

Acevedo is undeniably all about the future. You just need to talk to him about his long-time guru, AEM granddaddy John Concialdi, to understand where his sights are trained.

"John once told me, 'Ron, if you're getting into this industry, don't just think vertical or horizontal. Think big picture,'" Acevedo recalls. "We're not doing anything special or revolutionary here, just carrying on the traditions handed to us by our mentors. We're just trying to do our part and keep up."