| Stroke Recovery

| Stroke Recovery These are good days for people looking to make power with a GS-R motor. If you happen to own one of the much-revered powerplants, there is no shortage of options available for making significant gains underhood. Superchargers, turbos, nitrous - even the fine art of all-motor has been perfected so that the B18C1 can achieve 200-plus hp without the benefit of power adders.

And now you can add another choice to the selection: the stroker kit. A technology originally developed by musclecar tuners back in the day, stroker cranks boast a longer throw for increased displacement. The gains from the displacement bump are typically across the board, with more juice usually found on the bottom end of the powerband. In addition, the bigger stroke is good for a higher compression ratio.

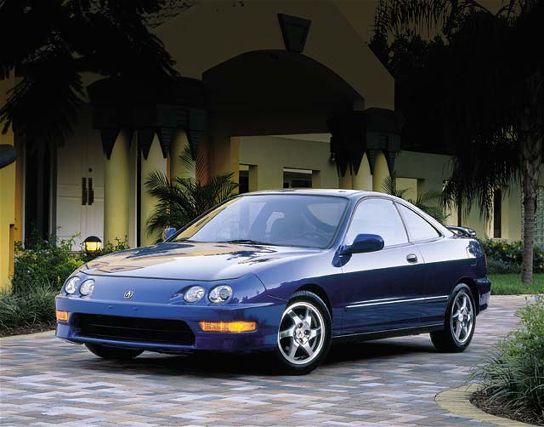

These benefits are exactly what Mike LaPier, a tech at Honda/Acura service center Auto Wave in Huntington Beach, Calif., was looking for. LaPier sought a unique way to get horsepower in the 235-240 range and his quarter-mile times down to the high 12s. He also wanted a car that wouldn't get him killed or attract lots of attention from the authorities. Most importantly he was hoping to keep his GS-R driveable and durable and it seemed like the stroker kit was the way to go.

LaPier tapped neighbor and ace engine builder Kurt Gordon of KG Precision Engineering to handle the project and Gordon quickly came up with a game plan. He decided to use the stroker kit that Eagle makes for the B18C1 but replaced the JE pistons that normally come with it with custom Arias slugs. Since a longer stroke means a higher compression height, the pin in the piston was changed so the piston won't top out above the deck. Additionally the piston skirts are coated with a moly-based anti-friction finish to protect the cylinder walls.

The kit also comes with LS-length Eagle rods that have been customized to handle GS-R bearings. The B18C1 block we will use for this project, which came from an insurance claim, was sent out to get bored to 84mm and sleeved with Darton sleeves. Finally, the cylinder head came off of LaPier's GS-R and will receive a whole new valvetrain and new cams for this endeavor. When all is said and done, the motor should have a renewed displacement of more than 2.1 liters.

Upon assembling the rotating assembly for balancing and blueprinting, we learn that the rod journals and counterweights on the crank are hitting the oil squirters and the main cap girdle (cradle) inside of the crankcase. Gordon suggests plugging up the oil squirter holes (the squirters are for the factory cast pistons anyway) with Allen head plugs that can be bought at most fittings stores. As for the rod journal hitting the girdle, some material needs to be notched out of girdle for clearance, which Gordon will take care of. So that's it for now - next time we put all the pieces together, match it to a tranny, and drop it into the Integra.