| Top 20 Basic Questions - Cylinder Head Porting

| Top 20 Basic Questions - Cylinder Head Porting The Basics

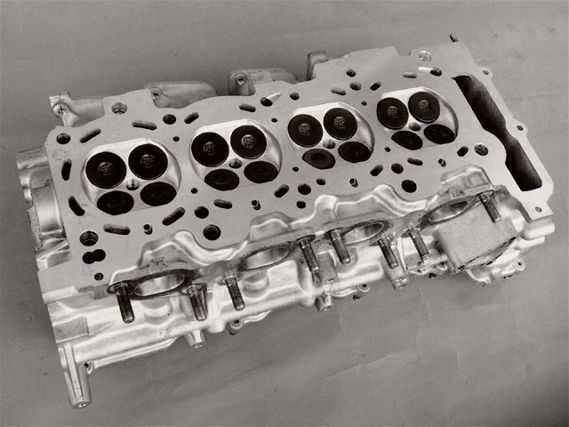

1) What is head porting and polishing and how does it work?Porting involves shaping and/or polishing the intake port openings, the inside of the ports, the exhaust ports, the bowl area below the valve seats and the combustion chambers to increase the head's ability to flow air. The process starts with a thorough cleaning, and then the disassembly and inspection for burnt and/or worn cam journals, stress cracks or other signs of terminal fatigue. Then the air tools are busted out.

2) What is port matching?The intake runner opening, or port of entry, is where incoming air enters the head. In untreated heads, incoming air must pass up and over obstructions caused by irregular fitment between the head and the intake manifold. This obstruction is called the step effect. Port matching solves this problem by providing a direct, uncluttered path from intake to head. "Matching" refers to matching the openings in the head and the intake manifold by using the intake gasket as a template. All the material inside the outline is carved out and the transition between the two components is seamless.

Similar to intake port matching, the exhaust ports are shaped to match a gasket. Since carbon is a byproduct of combustion, the exhaust ports are polished to a mirror-like finish to avoid build-up of carbon deposits, which can restrict flow.

3) What else is involved in a porting job?After port matching the intake, the action moves inside the runners where casting irregularities are removed and any radii where the air turns are smoothed.

In the bowl area, which includes the valve guide area, valve pocket and valve throat, all exposed surfaces are smoothed.

Work in the chamber starts by positioning the head gasket and tracing an outline of the head gasket on the head. No work is to be done outside the line because doing so will compromise gasket integrity. The porter smoothes the chamber, then the chamber is polished to a mirror finish. This reduces carbon build-up and eliminates sharp edges that can cause detonation.

4) What is a valve job?A valve job involves disassembling the head and reshaping the radius of the valve seats to ensure proper sealing between the seat and the valve. There are three-angle, five-angle and multi-angle valve jobs-these are all buzz words. If you plan to increase the size of the valves in the head, the valve job entails cutting the seat to accommodate the bigger valve.

5) What is the ultimate goal?Horsepower. There's an old saying: "Horsepower hides in the heads." Increasing airflow means more fuel can be added to the mix, and where there's more fuel, there's more power. Porting is an opportunity to correct oversights in production and tolerances made in the name of mass production.

What You Should Ask Your Head Porter6) How much does it cost?This is an obvious question, but some porters charge more than others and the type of head(s) in question can also affect pricing. For example, port matching only costs less than matching and chamber work. Prices vary, but remember, you get what you pay for.

7) What services do I get for my money?Do you deliver a bare head? Does the price include the porter delivering a completely assembled head back to you? Is the valve job part of the price? The price quote includes only labor costs. Any upgraded components (e.g. valves, valvesprings, etc.) are an additional charge to you.

8) What is your specialty?Work with a head porter who is familiar with the idiosyncrasies of your application. A 300ZX specialist should know that casting shifts in the water jacket area affects the number three cylinder. A Honda specialist should know to not alter the intake port angle of a B18 or the exhaust port angle of a B16 because they flow perfectly from the factory. A Subaru guy should know that bigger valves aren't the right call on EJ20s because there's little room between the valve seats to accommodate bigger units without eventually cracking the valve seal.

9) Do you flow bench the heads you work on?Port Flow Design's Tom Fujita says he's often asked, "How much power will the head make?" He doesn't quote power gains because engine tuners make the power head porters deal in airflow only. Flow bench testing is performed before and after the work and the cfm numbers illustrate the improvements in flow attained by the porter. This service is an extra cost option at Port Flow, but this policy may vary between shops. It's also important to know what lift (.050) the valves are at during the testing.

10) When doing head work, what other factors should be considered?With the head apart, there may be an opportunity to perform other upgrades. The more common of these include popping in a set of performance cams and upgrading the valvetrain for higher engine speeds. A high-revving valvetrain requires stiffer valve springs and heavy-duty retainers. Some applications can make due with the stock valves, while others may need performance valves. Weight is the enemy of the high-speed valvetrain and many of the upgraded components are made of titanium or other lightweight alloys.

What Your Head Porter Should Ask You11) Is it an all-motor or forced induction engine?Flow characteristics of these two motors are very different, and their operating characteristics will have an impact on the porting strategies used on the head. Fujita says he widens the 45-degree cut on valve jobs for forced induction motors to get a better seal in a pressurized environment and the added contact area pulls heat out of the valve.

12) How much boost is the turbocharged or supercharged engine making?The pressure and volume of air forced into the engine is key to the ported head's performance.

13) Are you running a sleeved block?This question allows the head porter to gauge the seriousness of the enthusiast. It's easy to say you're going full race, but if the proper steps aren't being taken elsewhere in the engine, the enthusiast's ego may be getting the better of him.

14) What kind of cam(s) are you running?Cams run the airflow show. They open and close the valves, and their lift and duration controls the flow of air in and out of the engine. The valve overlap of the cams is also a major consideration.

15) What are the spring retainer specs?Some retainers are designed to be recessed, which affects the size of the spring being used and when it will bind.

16) What is current/desired compression ratio?Combustion chamber work can be an opportunity to alter the compression ratio. Removing material lowers the compression ratio while welding in material is a way to increase the compression ratio.

17) What is the displacement of the engine (bore and stroke)?This info is needed to calculate the size of each combustion chamber. Also, when a larger bore size is used with a wild custom piston, valve/piston impact may occur. The right info allows the porter to calculate the proper clearance for the combination.

18) What do you intend to use this vehicle for-street or strip?This question will give the porter info he needs regarding the expected powerband of the engine, how fast the engine will be asked to turn and other important clues to creating a head that delivers on its power promise. It's also another opportunity to gauge the enthusiast's commitment and ensure the proper valvetrain parts are being used.

19) Will a factory intake gasket or a custom setup be used?This info is needed to properly port-match the head and intake manifold.

20) Can you afford me?Plain good business.