| Project Acura RSX Type S

| Project Acura RSX Type S

After Part 1, we received a stack (at least two) of readers' letters pointing out how lame it was that Project RSX's Cosworth-built turbocharged engine could do no better than 249hp at the wheels. Fortunately, we had already noted this in the article and said we'd worry about it later, when the rest of the car was done. That time is now.

To review, Project RSX made great torque, with a virtually flat plateau from 3500 to 7000rpm. It took a dive at 7000 (obvious from both the driver's seat and the dyno), making it pointless to pursue the 9000rpm redline enabled by its Ferrea valvetrain hardware. When adjusting the boost controller, we would see roughly 14psi in the midrange, but were unable to get more than 11psi by 8000rpm, which is only 1psi more than we got when running the wastegate on just the spring. This result is typical of flow-limited turbo systems.

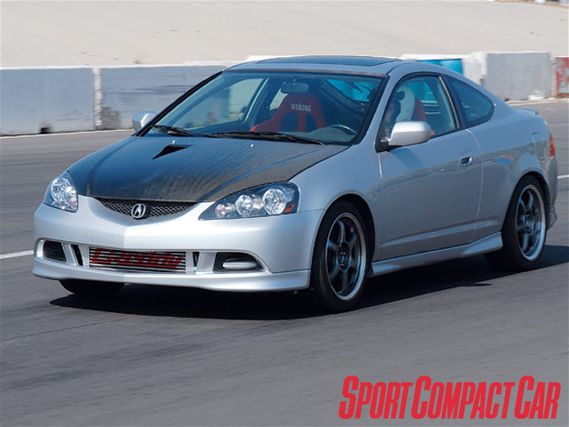

| On inexpensive street tires and with a dusty drag strip, Project RSX laid down a best zero-to-60mph time of 5.2 seconds and hustled to the end of the quarter-mile in 13.4 seconds.

| On inexpensive street tires and with a dusty drag strip, Project RSX laid down a best zero-to-60mph time of 5.2 seconds and hustled to the end of the quarter-mile in 13.4 seconds.

Megan Racing Test Pipe

The biggest flow restriction on Project RSX was the stock catalytic converter. The ceramic brick was beginning to deteriorate and thick soot covered all internal surfaces upstream. After some research, we decided the best off-the-shelf replacement was a Megan Racing test pipe. It's affordable and seems to be the standard choice in the RSX community for those wanting to make their turbo RSXs fast and stinky.

The pipe is a large, mandrel-bent tube that should flow freely. It comes nicely polished and the welds are good enough. The 'resonator' has an internal perforated core, but no packing we could see. Instead of studs on the exit flange, there are holes. Bolts with washers and locking flanged nuts are included, which actually makes assembly easeier when compared to the stock parts.

| The stock RSX cat (left) is divided to act as a 4-2-1 header without the added external surface area that increases the time required to light off the cat. It helps low-end torque when used with the stock manifold, but wasn't doing us any favors for power production.

| The stock RSX cat (left) is divided to act as a 4-2-1 header without the added external surface area that increases the time required to light off the cat. It helps low-end torque when used with the stock manifold, but wasn't doing us any favors for power production.

There were two significant issues with installation. The downstream oxygen sensor bung was clocked too high; it should have been in line with the first bung. We ended up notching our heat shield for clearance. The flange at the forward end of the test pipe is 7/16-in. thick, whereas the stamped steel flange on the stock cat is only 1/16-in. thick. This means the springs holding the flex joint together must be about 3/8-in. shorter when installed. In order to install the test pipe in the car and tighten the bolts, we cut one and a half coils off the spring used on the side with the block-to-downpipe brace (see Part 1, August 2006) and one and a quarter coils off the other, then ground them a little flat at the ends.

The installed springs are just short of coil bind. The spring preload is much higher than engineered by Acura and there is little room for movement. We seem to have actually gotten away with this because Project RSX's engine doesn't move around as much as stock. We believe the flex joint will not have enough flex to be durable over the long term with stock engine mounts.

| The Megan Racing test pipe has a larger diameter, with no impediments to flow.

| The Megan Racing test pipe has a larger diameter, with no impediments to flow.

Also note the amount of spring material we cut was greater than the remaining compression distance, so it seems likely that anyone who has installed this part without shortening the springs has the springs at bind, and thus no flex in the flex joint. A quick web search on the Megan Racing test pipe reveals many forum posts complaining about the difficulty of installation due to this issue.

The whole thing could be fixed by putting the flange in a mill and dropping an end mill on it to countersink the hole to the same thickness as the OE cat flange, with clearance for the spring. That would, however, add another piece of machinery to the manufacturing process.

Tuning

We took Project RSX to Church Automotive Testing in Wilmington, California, to have Shawn Church tune it. The tune we'd been running on was done shortly before our first OE cat melted. There was definitely work to be done.

| Due to increased flange thickness, we had to cut the flex joint springs in order to assemble the Megan Racing test pipe to the turbo downpipe flange and avoid spring bind.

| Due to increased flange thickness, we had to cut the flex joint springs in order to assemble the Megan Racing test pipe to the turbo downpipe flange and avoid spring bind.

Project RSX's 2140cc engine was machined and assembled by Cosworth, with 89mm-bore Darton sleeves, Crower forged rods, Cosworth 9.0:1 forged pistons, a Cometic head gasket, Ferrea valve springs and hardware, and ARP head studs. Nine thousand rpm of boostable, pump-gas sweetness. To that we added a GReddy turbo kit with intercooler and fuel system upgrades, controlled by an AEM EMS. As of our printing, AEM hasn't yet reverse-engineered the CAN bus for the 2005 RSX, so we make do with no speedometer, odometer, temperature gauge or air conditioning.

Church first cleaned up part-throttle and mid-boost maps, which were a little rich in some places and a little lean in others. The result was a more consistent air-fuel ratio across the board and better response getting in or out of the throttle. Step two was to stabilize the hot idle. We found the fuel trim adjustment relative to intake air temperature was set to 12 to 13 percent richer than the baseline with just a 20-degree increase in temperature from ambient. With an underhood intake, we had been dumping fuel into the engine at light loads for no good reason. IAT enrichment was dialed back to more appropriate values.

| Church Automotive Testing uses Dynapack dynamometers, which bolt to the hubs. Dynapack states that because there is little inertia, sensitivity to variations in the torque curve is improved, compared to systems using rollers. It also removes much of the drama, noise and danger from dyno runs. But we don't use Dynapacks for power numbers. So it was back to MD Automotive's Dynojet for our published figures.

| Church Automotive Testing uses Dynapack dynamometers, which bolt to the hubs. Dynapack states that because there is little inertia, sensitivity to variations in the torque curve is improved, compared to systems using rollers. It also removes much of the drama, noise and danger from dyno runs. But we don't use Dynapacks for power numbers. So it was back to MD Automotive's Dynojet for our published figures.

Step three was to check the mixture at wide-open throttle. A huge dip in torque came when iVTEC kicked in, because the big cam requires different timing at that engine speed than the little cam. Increased flow allowed by the test pipe had leaned out some areas of the map to as high as 13.5:1. Church brought the mixture at WOT down to roughly 13.0:1 across the rev range. Once the car was running safely, Church set about filling in holes in the torque curve. With the cam angle control capabilities of the AEM EMS, it wasn't possible to make the iVTEC transition perfectly smooth, but Church minimized disruption to the torque curve. He also filled in a significant dip between 6000 and 7000rpm.

The Numbers

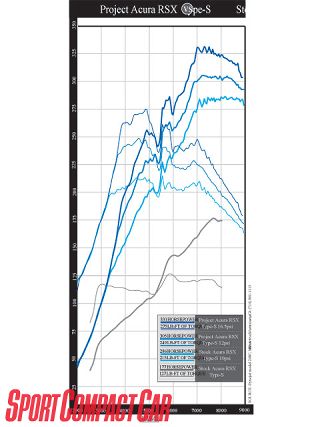

Running on the stock boost setting, using only the wastegate spring, Project RSX held a constant 10psi from way down low all the way up past 8000rpm. The result of the freer breathing and tuning was a 37hp increase to 286 wheel-hp, and power stayed within a handful of that number from 7000 to 9000rpm. The torque curve was wide and flat, peaking in two places at 215lb-ft, and staying at or above 200lb-ft from 3500 to 7500rpm. The only interruption was the iVTEC transition, in which torque fell from 208 to 195 and bounced back to 215lb-ft between 5000 and 5500rpm.

| Shawn Church doesn't work on cars, he just tunes them. Dialing in several cars a day, every day, he sends a steady stream of faster, more driveable machines out onto the streets and race tracks of Southern California. You probably can't tune your car better than he can.

| Shawn Church doesn't work on cars, he just tunes them. Dialing in several cars a day, every day, he sends a steady stream of faster, more driveable machines out onto the streets and race tracks of Southern California. You probably can't tune your car better than he can.

Church set the low boost on the GReddy Profec-B boost controller to run about 12psi, which is maintained essentially towards redline and made WOT fueling at this level a bit richer throughout the rev range. The car responded with 249lb-ft at 4600rpm and over 300 wheel-hp from 7000 to 8400rpm. Power is within a few hp of that until 8400rpm, where it tapers off gently and the torque curve rocks slightly toward the right, relatively stronger in the mid-range than higher up.

The high boost setting ended up peaking at 16.5psi, but with the boost controller still attempting to drive the system to that level, actual manifold pressure tapers to just 13.4psi at 8000rpm. We considered that to be the flow limit of this GReddy turbo system. You might be able to get a little more air through it, but it would be hard. Boost could be slightly higher with a 1998cc engine, but you wouldn't want to run these levels on a K20 without either race gas or reduced compression. And you still wouldn't make much more power. The Dynojet at MD Automotive liked Church's handiwork, responding with 275lb-ft at 4600rpm and 331 wheel-hp at 7300rpm.

New Tires

By this time, we had worn out our Yokohama A032s, and needed new tires. Really sticky tire choices in Project RSX's 235/40/17 size are limited. We briefly considered another set of race tires, but eventually came to our senses and settled on Hankook's Ventus Z212 street tire. Hankook states this tire is derived from the Ventus RSS Z211 race tire, but with a more streetable tread compound. We can't help but notice the tread molded into a pattern that resembles the excellent Yokohama Advan Neova tire more than just a little bit. We'd heard good things about the Ventus Z212, especially for the price, so we went ahead and mounted them for testing.

| Hankook's Ventus Z212 held up reasonably well during our testing.

| Hankook's Ventus Z212 held up reasonably well during our testing.

Track Testing

Our figure-eight test loops back and forth around two, 200-foot diameter circles with centers set 500 feet apart. This is a comprehensive evaluation of all aspects of a car's performance: acceleration, braking, corner entry, steady-state cornering balance and corner exit.

Downshifting to second under braking made it difficult to enter turns smoothly, provided wheel spin on corner exit, and cost time on the throttle when an upshift was required on each straight. Running in third gear all the way around at low boost, we got a time of 25.3 seconds. Turning boost up to high required feathering the throttle a lot more on corner exit to manage wheel spin, but we found that, given the same tires, horsepower is the key to a faster lap time. At least with the Quaife Automatic Torque Biasing differential, both wheels were spinning and the braking point came a lot earlier. We dropped to 25.0 seconds flat. That's a stout number in this test, as a Ferrari F430 sets a time of 24.9. The record, set by a Porsche 911 GT3 on super wide R-comps, is 24.8. When we realized how close we were, we really started to miss our R-compounds.

| Project Acura RSX Type S

| Project Acura RSX Type S

On the skidpad, Project RSX worked well. Going to the left, it was balanced on the loose side of perfect, its steady-state condition just a little tail-out. It could be brought in with the throttle or thrown sideways with a big lift. With the battery hanging over the front axle on the driver's side, going right matched what you would predict from the corner weights. The car was much tidier in this direction; still better balanced than virtually any stock front-wheel-drive car, but not as fun nor as fast as going left. The numbers tell the story: 0.9g to the right and 0.92g to the left, for an average of 0.91g.

And that's just OK for an SCC project car. One thing was obvious: our testing surface was extra-dirty that day, with the insides of the rear wheels eventually coated with dust, as if we had driven down a dirt road. Follow-up testing a week later at the same facility showed a roughly 0.05g increase. A 0.96g result, if we could realize it, is very favorable for tires at the price point of the Hankook Ventus Z212 and we're confident R-compound tires would be able to make 1g on a clean surface.

| The oil feed line for the turbo is forced against parts behind the engine when the engine moves on its mounts. We wrapped it in wire loom to protect other components from rubbing against it, but couldn't protect it from vibration fatigue and the force of contact. It began leaking and coated the back of the engine.

| The oil feed line for the turbo is forced against parts behind the engine when the engine moves on its mounts. We wrapped it in wire loom to protect other components from rubbing against it, but couldn't protect it from vibration fatigue and the force of contact. It began leaking and coated the back of the engine.

In the quarter-mile, launching at any boost level was severely traction-limited, with the front wheels visibly flopping around all over the place. The best zero-to-60mph times came with 10psi of boost at 5.2 seconds. The quarter-mile was over in 13.6 seconds. At the high boost setting, wheel spin added 0.1 of a second to the 0-to-60 time, but shaved 0.2 off the quarter for a best of 13.4 seconds with a trap speed of 113mph. If we had several hours for testing, we may have been able to dial in better alignment, tire pressure and damper settings, but the sun was low and the ambulance crew was getting antsy. Our 214-foot 80-to-0mph stopping distance with the Stoptech four-piston front brakes was mere feet longer than what the already well-balanced stock brakes could put together, but the big improvement was in pedal feel. Look on page 112 for details on our complete and painful brake test.

ConclusionProject RSX is a success, in that we built what we set out to: a performance-focused machine that's more fun to drive than is legal in any state. One might rightly question the point of having this much power in a front-wheel-drive car, as it's difficult to put even mid-boost torque to the ground. Project RSX lost a little of its magic on street tires, but still behaves impeccably and is far more competent than most cars. For sure, it would be at home and make the most sense on R-compound tires at the track, fully committed to filling out the traction circle.

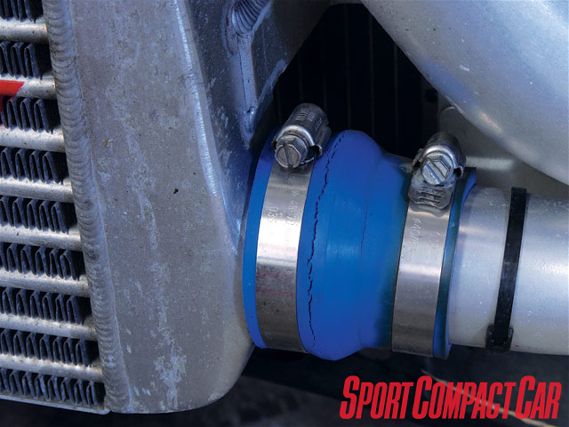

| This molded polymer connector is not reinforced and has not handled heat and boost well. No leaks yet, but failure is clearly imminent.

| This molded polymer connector is not reinforced and has not handled heat and boost well. No leaks yet, but failure is clearly imminent.

And while we never brought out a stock MazdaSpeed3 to compare against our RSX in a face-to-face track battle, the numbers alone show that our project car would have given the production turbocharged MS3 the beating of its life. Of course, we don't have traction control, four doors, A/C, or gauges, for that matter.

If we were to do it again and buy another RSX Type-S to use as a daily driver, the engine would stay mostly stock, with maybe a cold-air intake and remapping of the stock ECU. While its turbocharged engine is the heart of Project RSX, it is also by far the most expensive part, and the system that brings the most serious compromises and unreliability to the overall vehicle package. If you want the benefits, just know that going in. n