| Project MR2 Spyder - Part 4

| Project MR2 Spyder - Part 4

Despite the stellar improvements in handling and chassis response wrung out of our Project MR2 Spyder, there has been little fighting over who takes it home for the night or out for a weekend thrash. With a wide variety of equally fun and eminently more practical hardware available for our daily drives, it takes more than just fabulous handling to pique our jaded interests. Of course, the fact that it sat for almost a year at XS Engineering (waiting for a new engine, rag top, and turbo kit) made it that much easier to avoid. But we're back behind the wheel with a vengeance.

Able to deliver 1.03gs of gut-shuffling lateral stick while snaking through the 600-foot slalom at nearly 73mph, it's clear that Project MR2 delivers world class chassis dynamics. But the stock 1.8-liter engine's uninspired performance brings sighs, musings and mostly doubts regarding our lofty goal of beating a Lotus Elise at this game.

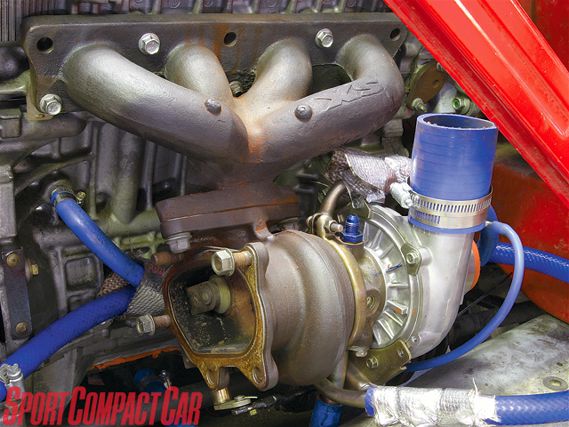

| Installing the turbo on the MR2 ends up being a lot easier than on many other cars once the rear cosmetics have been removed. There's plenty of room to pull off and bolt on the hardware.

| Installing the turbo on the MR2 ends up being a lot easier than on many other cars once the rear cosmetics have been removed. There's plenty of room to pull off and bolt on the hardware.

A quick review of the SAE 'white paper' on Toyota's design objectives for the MR2's 1ZZ-FE engine reveals only two of the six major goals outlined by the engineers had anything to do with performance: a flat torque curve and class-leading low weight. The rest had to do with friction, emissions, noise and cost reduction. It's an interesting read, outlining the innovative ideas Toyota incorporated to achieve those goals. From a nerd's point of view, the text on improving the combustion stability and volumetric efficency is fascinating, but geeks need testosterone-pumping, class-leading horsepower and torque as much the next guy, and there was little of that in the paper, as the final product illustrates. For reasons best known to Toyota, it created the perfect powerplant for an appliance instead of a sexy two-seater. Yawn.

Perhaps the lack of muscle is excusable when considering the MR2's low mass of 2250 pounds. It's amazingly light for a regulations-strapped, mandatory-safety-equipment-laden modern car that's not made from glue and sheet aluminum.

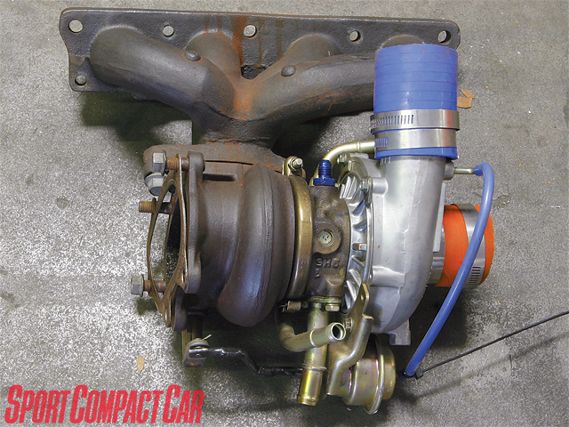

| The heart of the XS turbo kit is the IHI VF23 with a P20 exhaust housing and internal wastegate. The turbo not only uses a ball-bearing center section, but is also water cooled. The kit uses a 2ZZ sil-moly smooth flow cast-iron manifold.

| The heart of the XS turbo kit is the IHI VF23 with a P20 exhaust housing and internal wastegate. The turbo not only uses a ball-bearing center section, but is also water cooled. The kit uses a 2ZZ sil-moly smooth flow cast-iron manifold.

We repeated baseline measurements with the fresh engine (one without spun bearings) on XS Engineering's Dynojet 248E, where 115 wheel-hp and 115lb-ft of torque was pumped out with all the drama of a Singer sewing machine ripping out a topstitch. Even when considering the MR2's lack of bulk, the power to weight ratio still ends up at a nap-inducing 19.6:1.

Few relatively simple or economical options exist for better motivating the 1ZZ motor, since the usual bolt-ons can't change or disguise the fact that the combustion chamber was designed by someone who might be better suited to accountancy. A common solution is to dump the engine altogether and drop in the higher-revving 2ZZ motor shared by the GT-S Celica and Lotus Elise, but even that engine is not so receptive to simple mods.

The 2ZZ is peaky, with a narrow powerband and not the most pleasant to drive. Furthermore, the costs and headache - not to mention our brand new engine - make any swap impractical.

| The turbo is a straight bolt-on with plenty of tool clearance. The manifold studs are replaced by bolts in the kit and the water and oil lines are all provided.

| The turbo is a straight bolt-on with plenty of tool clearance. The manifold studs are replaced by bolts in the kit and the water and oil lines are all provided.

The Turbo

To get the most streetable bang-for-the-buck power, our eyes turned toward forced induction. After much nagging and cajoling, we convinced Eric Hsu of XS Engineering to consider turbocharging our car as part of the development for a line of bolt-on XS Engineering turbo kits for the platform. Turbocharging is good simply because it gets the greatest gains with the least amount of fuss. Done properly, it would also give us the widest powerband and the most flexible power delivery. Normally, it's the pricey alternative compared to bolt-ons, but since none of them do wonders for the 1ZZ, a turbo system is our best (and only?) option. The good news is that the XS kit will come with an exhaust, intercooler and intake, which should save a good chunk of change versus buying the parts separately. The production kit will also look a lot better than our prototype kit pictured here.

| Part of the kit is a new reverse-flow baffled exhaust that mounts the muffler higher and horizontally, compared to our old exhaust. This is to make room for - and keep heat high above - the massive GT-R intercooler.

| Part of the kit is a new reverse-flow baffled exhaust that mounts the muffler higher and horizontally, compared to our old exhaust. This is to make room for - and keep heat high above - the massive GT-R intercooler.

XS uses the 2ZZ cast iron manifold from its Celica GTS turbo kit. Getting the manifold to mate with the 1ZZ cylinder head requires minor modifications to the cylinder head bolt pattern, and using bolts rather than studs. The manifold is made of heat-resistant, high sil-moly cast iron, a grade of ductile iron with a high silicone content for clean castings, with the addition of molybdenum and nickel for exceptional heat resistance. It's cast as a smooth, curving 4-1 design with good, flowing entrances into the turbine inlet, despite a compact design; far better than most cast or weld-el log manifolds.

Like any stock motor, the stock 1ZZ can only reliably take a half atmosphere (roughly 7psi) of boost pressure. To compensate, XS uses a smaller, lag-free IHI VF23 turbo for the kit. The compact VF23 is a popular aftermarket upgrade for mild tuned 2.0-liter WRXs because of its responsiveness when used in medium-displacement four-cylinder engines. Like most OE-style turbochargers, the VF23 has a ball-bearing, water-cooled center section for quick spooling and superior durability. Hsu sized a P20 exhaust housing for the turbo, which left us scratching our heads. We have no clue how big this housing is, since IHI doesn't use a typical industry standard of area ratio for their turbo housings (apparently P20 is IHI code for cross-sectional area of the turbine housing volute and is not useful for comparison to any other brand of turbos).

| Our prototype kit uses a divorced discharge pipe at the turbine outlet to reduce backpressure and turbulence from the wastegate discharge flow. Sometimes this can be good for at least 10 wheel-hp.

| Our prototype kit uses a divorced discharge pipe at the turbine outlet to reduce backpressure and turbulence from the wastegate discharge flow. Sometimes this can be good for at least 10 wheel-hp.

Just like the production kit, our VF23 has an internal wastegate for boost pressure control and low inertia compressor and turbine wheels for fast response. The turbine discharge dumps into a 2.5-inch diameter exhaust silenced with a reverse-flow muffler positioned horizontally to make room for the intercooler. Although more restrictive, the reverse-flow muffler was deemed necessary to sufficiently quiet the MR2's extremely short mid-engine exhaust system. Unlike the production kit, XS fabricated a divorced discharge pipe for the wastegate that reintroduces the wastegate discharge flow back into the exhaust, several inches downstream of the turbo. This feature is usually good for at least 10 wheel-hp and reduces backpressure and lag by preventing the exhaust flow in the turbine outlet from slamming into the wastegate discharge. Our prototype turbo system's exhaust is made of coated mild steel, the production kit will be made of 304 stainless steel.

One of the worst things about turbocharging a mid-engined car is the difficulty in situating an effective intercooler. There is simply no good place to put a traditional air-to-air intercooler where it can get adequate airflow.

| The expanding boost piping is short and elegant, part of the reason for the immediate turbo response we love.

| The expanding boost piping is short and elegant, part of the reason for the immediate turbo response we love.

On the MR2, the turbo's pressurized air is directed to a huge tube-and-fin GT-R intercooler mounted under the car and the now horizontally-mounted muffler. This unusual mounting position keeps the intake track short for the best possible throttle response and sufficient flow. To direct airflow through the intercooler, a large scoop picks up underbody air and directs it up through the core and into the lower-pressure engine compartment. It's unorthodox, but XS's testing shows intake air temps of 105 degrees F on the street and 122 degrees F when being pounded at a track in the middle of the desert. XS claims this is as effective as a conventional front-mount system.

The intercooler piping diameter is kept small to minimize volume and to speed up the flow; the tubing starts off at 2.25 inches, steps up to 2.5 inches after the intercooler and finally flares to 2.75 inches at the throttle body. The prototype tubing pictured here is mild steel, but the production bits will be a lightweight and higher quality 0.040-inch thin wall stainless steel. The XS kit also uses high quality multi-ply silicone couplers and clamps to prevent blowoff.

| XS relocates the air filter to the passenger side for simplicity's sake, but this cannot take advantage of the stock air intake ducts on the driver's side.

| XS relocates the air filter to the passenger side for simplicity's sake, but this cannot take advantage of the stock air intake ducts on the driver's side.

Since the 1ZZ motor has a turbo-unfriendly compression ratio of 10:1 and fragile pistons with the ring lands close to the crown (for emissions reduction), the boost pressure has been limited to 7.5psi. With such a low figure, XS has deemed the use of a blowoff or compressor bypass valve unnecessary. The IHI turbo's ball-bearing center section is exceedingly tough and can easily handle any momentary surge that a lack of blowoff valve may produce. The large-volume intercooler also acts as a big surge chamber to buffer spikes in boost pressure.

As a somewhat unusual step, XS has located the mass airflow meter (MAF) on the pressurized side after the turbo's compressor. The MR2's topography makes it difficult to mount the MAF far enough from the compressor inlet to avoid the turbulence and pulsation generated by the turbo. XS has found that this 'blow-through' configuration gives more accurate and stable metering, as there is less turbulence after the massive intercooler to throw off MAF readings. Although our SVT Focus had issues with this type of MAF configuration, XS mounted the sensor far enough away from the turbo to make it work, and it actually measures the transient flow more accurately.

| The unconventional rear mount intercooler uses a bottom scoop to direct cool air up through the cooler and into the engine. Production models will have a stainless or fiberglass air scoop.

| The unconventional rear mount intercooler uses a bottom scoop to direct cool air up through the cooler and into the engine. Production models will have a stainless or fiberglass air scoop.

The XS MR2 kit is almost entirely a bolt-on affair, except for some welding required for the drainback bung on the oil pan. Fortunately, this is a fairly simple bit of welding that nearly anyone can get done locally.

Engine management

With fragile high compression pistons in the 1ZZ, careful attention must be paid to engine management. Although the fuel system (fuel pump and injectors) are an optional part of the turbo kit that jacks up the price, we highly recommend going with the XS fuel package to ensure trouble-free operation. The stock injectors are replaced with 525cc/min units to insure adequate headspace for turbocharged operation. Likewise, the fuel pump is ditched for a high-capacity Walbro 255lph unit. If more boost is desired later, as in the case of an owner installing forged lower compression pistons, this fuel system can support upwards of 400 wheel-hp.

| ACT's heavy duty pressure plate and performance street disc were put into Project MRS, since the stock clutch would only last two launches with the new-found torque.

| ACT's heavy duty pressure plate and performance street disc were put into Project MRS, since the stock clutch would only last two launches with the new-found torque.

The stock ECU is replaced with an A'PEXi Power FC standalone engine management system. Although A'PEXi's Power FC for the MR2 was meant only for the Japanese-market Spyder, the harness and algorithms are identical and will plug in directly - even though it comes with a base map only suitable for JDM cars. This base map won't matter, since the ECU must be retuned for the turbo and larger injectors anyway. The Power FC for the MR2 is one of A'PEXi's most developed applications - it can mimic factory ECU functions even down to automatically switching ignition maps based on knock sensor activity, saving the engine from low octane detonation. Using the Power FC also saves us the headache of modifying the fuel system with return lines.

It's no secret that Eric Hsu is one of the best tuners in the country. He's spent a lot of dyno, track and keyboard time to assure the tuning of the XS turbo kit is optimal from both a performance and reliability standpoint. In normal street driving, the MR2 exhibits exceptional lag-free driveability, which is helped somewhat by the lack of blowoff valve. The engine feel is everything a good turbo system should be, with linear boost response and the sensation of a larger displacement, exactly what we had targeted. XS hit the nail on the head by creating something that feels like what Toyota should have created in the first place.

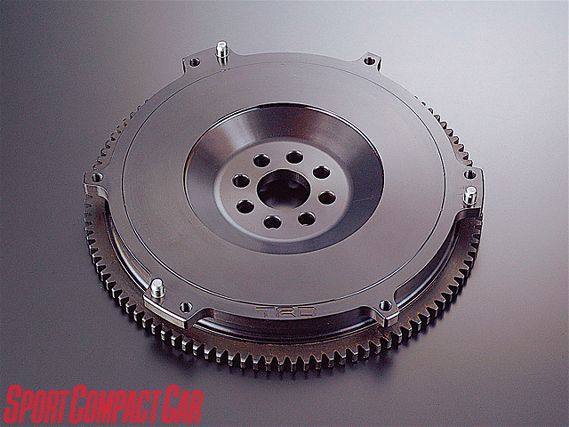

| TRD's lightweight chromoly flywheel was put in to help with engine response and more precise clutch and throttle control.

| TRD's lightweight chromoly flywheel was put in to help with engine response and more precise clutch and throttle control.

Back on the dyno, the 1ZZ delivered 216 wheel-hp and 198lb-ft of torque, an amazing increase of 100 more hp, especially considering the low 7.5psi boost pressure. To get that much more power out of the 1ZZ in naturally-aspirated form would mean a seriously expensive engine build and a very definite lack of driveability in street operation.

Anticipating the huge jump in torque our boosted motor will make, we replaced the stock clutch with an ACT heavy duty pressure plate and performance street disc combination. This street performance clutch only mildly increases pedal pressure while offering a 30 per cent gain in clamping force, which adds up to about 230lb-ft of torque. Engagement is smooth and predictable since the disc retains a sprung hub and a marcel spring. It also uses a semi-metallic friction material that will take loads of abuse and still operate at the high temperatures created when slipping the clutch on acceleration runs.

| A'PEXi's JDM Power FC software is among the most advanced offered by A'PEXi and allowed XS to tune the MR2 to run as sweetly as a standard model.

| A'PEXi's JDM Power FC software is among the most advanced offered by A'PEXi and allowed XS to tune the MR2 to run as sweetly as a standard model.

While we were in there, we replaced our stock heavy iron flywheel with a lightweight TRD version made of higher strength chromoly steel. The stronger alloy allows TRD to take several pounds of material while maintaining the same strength and reducing inertia for better throttle and boost response.

Our infusion of power has transformed Project MR2 in other ways as well. Every five minutes, someone on staff now comes by to try and steal the keys. With our power to weight ratio now sitting at a bit under 10.5:1, we're in serious world class performance car territory. And the car can give thoroughbreds like the Lotus Elise a run for their money with no sacrifice in civility or tractability. Our XS-tuned system has proven reliable in withstanding our track torture as well. But best of all, since we talked XS into doing it, you can simply step up and buy a better, more finished kit than we have. Next time, we'll throw on some sticky rubber, trackable pads and pray for victory. Stay tuned.