The importance of a well-designed and fully functioning braking system has never been more apparent to me than during my last visit to the racetrack. I was driving my dad's '06 C6 Corvette in a local time attack event-a hobby we've shared for about a decade now-when on what would have been my last lap of the day the OEM brake line on the front driver-side caliper failed. The flexible rubber line that crimps into a banjo bolt fitting that connects to the caliper separated at the crimped joint, leaving me with virtually zero stopping power as I entered a high-speed braking zone. As a result, when I hit the slow pedal at my usual braking point, the pedal went to the floor and stayed there while the Corvette and I continued at full speed off the track and into the weeds. Luckily for me (and the car), the trajectory of the run-off didn't carry me into the nearby wall, and the soft, loose dirt helped slow the car without rolling it. Part of the outcome was dumb luck, part was having enough experience to know to go straight off and keep the steering wheel centered so that the car doesn't pitch sideways too violently, which can lead to a rollover.

|

Lucky for me, the run-off area was soft grass and dirt rather than a concrete wall when the rubber brake hose to the front left caliper failed on the C6 Corvette I was driving.

|

Lucky for me, the run-off area was soft grass and dirt rather than a concrete wall when the rubber brake hose to the front left caliper failed on the C6 Corvette I was driving.

To satisfy my curiosity, confusion and sense of horror over this unexpected brake hose failure, I've been doing a little research on the flexible hose portion of the brake line system. That includes taking a closer look at the durability and reliability of OE rubber lines versus aftermarket high-performance lines that use a PTFE (Polytetrafluoroethylene, commercially known as Teflon) inner hose core that's wrapped in a braided stainless steel outer layer. Here's what I've learned so far.

As I'm sure you already know, a modern hydraulic braking system uses fluid stored in the master cylinder to transfer the force you apply to the brake pedal to the caliper pistons, which squeeze the brake pads against the rotors to generate enough friction to slow the vehicle. Considering the fluid in the brake lines is what ultimately moves the caliper pistons and provides the clamping force on the rotors, it's obviously a critical part of the system and any interruption or severing of its ability to build and apply pressure within the caliper will drastically reduce stopping power.

|

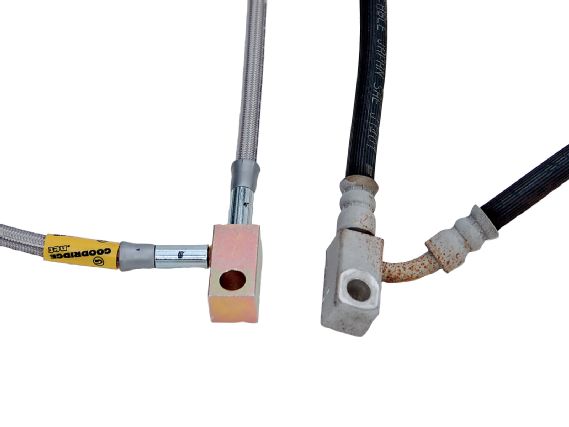

Goodridge's PTFE braided stainless steel brake hoses (left) like we got from Stillen.com for Project G35, have been shown to have significantly higher safety factor during burst/working pressure tests and whip tests than rubber OEM brake hoses (right), making them a must for anyone who takes their car to the track.

|

Goodridge's PTFE braided stainless steel brake hoses (left) like we got from Stillen.com for Project G35, have been shown to have significantly higher safety factor during burst/working pressure tests and whip tests than rubber OEM brake hoses (right), making them a must for anyone who takes their car to the track.

Given the consequences of a punctured or severed flex line, the durability and reliability of this part of the brake line system is particularly important. All vehicles sold in North America must be equipped with flexible brake lines that meet or exceed NHTSA Federal Motor Vehicle Safety StandardNo. 106 and SAE standard J1401 for volumetric expansion, burst pressure/working pressure and whip test (repeated flexing). These standards specify the performance tests and requirements for hydraulic brake hose assemblies used in the hydraulic braking system of a road vehicle, and they also specify the methods used to identify the manufacturer of the hose. These standards are specifically aimed at brake hose assemblies made of hose fabricated from yarn and natural or synthetic rubber and assembled with metal end fittings (like the aforementioned banjo bolt fittings) for use with nonsynthetic DOT brake fluid. The SAE standards even specify that the hose must be either 3.5mm or less in internal diameter or between 4-5mm in internal diameter.

So if all cars come equipped with flexible brake lines that meet these standards, why would anyone upgrade to PTFE braided stainless steel brake lines? Goodridge, one of the world's leading manufacturers of flexible brake hoses, with customers that include Formula 1, IRL, NASCAR and WRC teams and supplier to Alcon, AP Racing and Brembo for their brake kits, did a recent study of OE rubber brake hoses versus its PTFE braided steel hoses and found a number of interesting differences.

When testing volumetric expansion, Goodridge found that standard OE-type rubber brake hose expanded by 0.136 cc/ft at 1,000 psi, 0.150 cc/ft at 1,500 psi, and 0.290 cc/ft at 2,900 psi, whereas the company's PTFE braided stainless hoses expanded by only 0.0002932 cc/ft at 4,000 psi. The close-to-zero expansion to the braided hose means the brake pedal will feel firmer and will respond more quickly to brake pedal inputs, and if you've done any racing then you'll know that even a split-second faster response from the braking system can mean the difference between slowing enough to make the corner and finding yourself parked backward in the weeds.

|

Notice the relatively crude way the rubber OEM brake hose is crimped into the metal fitting (right), whereas the Goodridge braided hose (left) is connected to the metal fitting via a patented swage tail design that has been tried and tested in the upper echelons of racing, including F1 and WRC.

|

Notice the relatively crude way the rubber OEM brake hose is crimped into the metal fitting (right), whereas the Goodridge braided hose (left) is connected to the metal fitting via a patented swage tail design that has been tried and tested in the upper echelons of racing, including F1 and WRC.

When conducting the burst/working pressure test as defined by the FMVSS106 and SAE J1401 standards, Goodridge's PTFE braided hoses burst at 12,750-13,500 psi, which is triple that of the 4,250 psi required by the standard for this type of hose. By comparison, the OE rubber lines tested burst at 8,000-9,000 psi, with a recommended safe working pressure of 3,600 psi. What this means is that the PTFE braided hose provides a safety factor of 3, whereas the rubber hose provides a safety factor of 2.36.

The whip test standards require that "a hydraulic brake hose assembly shall not rupture when run continuously on a flexing machine for 35 hours." When Goodridge conducted its testing, the company found that the OE rubber hoses from five different manufacturers failed in 15 to 27 hours, whereas six sets of tests carried out on PTFE braided hoses of various lengths resulted in 45 to 82 hours of flexing before rupturing. What this means is that even though the rubber hose manufacturers claim compliance with the FMVSS106 whip test standard, Goodridge's internal testing showed failure of these hoses long before meeting the minimum 35-hour requirement, while its PTFE braided hoses far exceeded this standard.

It's also a little-known fact that rubber brake hose is generally only guaranteed for three years or 60,000 miles because rubber loses its elasticity over time. I've never really thought of brake lines as a wear item that need regular replacement, but having discovered this limited life expectancy for rubber lines, anyone with a car more than three years old should take a very close look at the condition of their brake lines and replace them if they show any signs of wear and tear. And if you're going to replace them, upgrading to stainless braided PTFE hose makes a lot of sense in light of the firmer pedal feel and faster braking response they provide as well as the increased safety factor illustrated by Goodridge's internal testing. It's also worth noting that Goodridge offers a 150,000-mile guarantee on all their brake lines, made possible by the greater durability of the PTFE liner and stainless braided outer layer.

Having a brake line fail and losing virtually all stopping power as a result is a shocking and extremely dangerous experience. I got extraordinarily lucky to escape unharmed, and although the Corvette sustained a fair bit of paint and underbody damage, it appears to all be easily repairable. Whether the line failed due to a manufacturing defect or damage to the rubber hose sustained during servicing or from road debris, we'll never know. But given the higher safety factor and far greater durability of a PTFE stainless steel braided brake hose, there's no doubt in my mind that equipping the car with these before racing it would have avoided this "Dukes of Hazzard"-style trip through the infield. Live and learn, and I hope you take this experience to heart and consider a brake line upgrade on your vehicles or at least inspect and replace the factory rubber brake hoses regularly.