If you're thinking about upgrading your brakes, you'd better like choices. Do you want four pistons in your calipers? Or maybe six, or eight? Rotors with cross-drilled holes, slots, or both? Wanna go big with those rotors? Would that be solid or two-piece discs? And how do you take your pads? Organic? Semi-metallic? Mild or hot? With a side of ranch dressing?

| Brake Upgrade - Stop It!

| Brake Upgrade - Stop It!

For some, the choice is easy. All a show car really needs is the biggest, wildest looking brake kit that'll fit behind those tall, wide-open rollers. If, on the other hand, you're interested in improving actual brake performance more than aesthetic appearance, all those above choices, and more, pertain to you.

With that in mind, what follows is a description of what a brake upgrade can do for you and the roles that the brake system's various components play in improving stopping performance. As usual, we've talked to several experts in the field, and, as usual, they don't always agree. So weigh the information here, visit the Web sites, and above all, talk to the brake companies about your car and your specific driving needs. As you'll see, no single brake upgrade will work for every car in every driving condition.

When Do You Upgrade?

Given the current state of original-equipment brake technology-which, our experts agreed, is pretty damn good-a well-maintained stock brake system should work just fine in an unmodified car that's used for typical daily transportation.

In fact, Dan Barnes of StopTech surprised the heck out of us when he said, "If you have a properly-functioning, well-designed brake system already, the only thing you can do to improve single-stop braking distance is get better tires. Any force that accelerates, slows or stops the car can only be applied through the tire's contact patches. If your current brake system is using all four tires to stop the car as effectively as possible, no brake system change will result in a shorter stopping distance."

So if better brakes won't help you stop shorter, what will they do? Here's Chris Bernal, brake division manager for Stillen: "Let's say a guy goes to a track day once in a while, or he drives the canyons hard, going deep into corners-within the legal limits, of course. He's building heat in the brake system. Most vehicles as delivered from the factory have great brake systems to keep from hitting people in crosswalks, but not to deal with heat buildup. If you're feeling brake fade or a soft brake pedal, you need an upgrade."

Modified cars are prime candidates for upgraded brakes. "Anyone increasing horsepower to achieve higher vehicle speeds, or upgrading to wheels and tires with a bigger circumference or a larger traction footprint, should also be considering enhancements to the braking system," said Wilwood's Carl Bush. Added Dominic Chen of Endless USA, "As you increase horsepower it becomes more necessary to increase brake power. But you want to keep it proportional. Add 500 hp and you'll want a substantial increase in braking power. A 20 hp increase, on the other hand, won't need as much."

How Brakes Work

Notice some of the words that those comments had in common? "Fade" was one. "Heat" was another. To understand why, you should know a little about how brakes work.

Like a lot of what goes on in our cars, braking is all about transferring energy from one state to another. "Brakes convert the kinetic energy of your moving car into heat," explained Barnes. That heat is "temporarily stored in the brake components-mostly the pads and rotor-and then shed into the surrounding air. Some heat is transferred into the wheel, hub, caliper and other places rather than to the air directly, but it eventually all gets into the air."

Brake fade occurs when the heat generated by hard or repeated stops exceeds the brake components' optimal temperature range. "Fade can happen when the brake pad's friction material and rotor are too hot," explained Mark Valskis, Brembo North America's Chief Engineer. "Beyond that, assuming you have a pad upgrade but stock rotors, you might have problems with heat soaking into the calipers and boiling brake fluid. Either will result in dramatic reduction in brake performance."

Because heat is such a critical factor in braking, many of the components in a brake upgrade-from the pads and rotors to even the brake fluid-are designed to either dissipate heat or operate effectively at higher-than-normal temperatures. Yet thermal stability, and the resulting brake performance consistency even under harsh conditions, are just part of what you get from a good brake upgrade. You should also expect greater stopping power, the proper balance in braking force between your front and rear tires, better brake modulation and a firmer pedal. All of these traits combine to improve the brakes' overall "feel" and enhance your driving confidence, especially when braking late on your favorite canyon road or coming up to that nasty right-hand hairpin turn lap after lap after lap.

A Little Extra Padding

Though a big-brake kit's massive rotors and multi-piston calipers generally hog all the attention, brake upgrades actually come in many shapes, sizes and-luckily for most of us-budgets. Remember Chen's comment earlier about keeping an upgrade proportional to a car's performance level? For many, a simple brake pad upgrade will provide all the braking boost you need.

Pad technology is complex enough to warrant its own article, so we'll try to keep it simple. The two main characteristics you're looking for in a performance pad are its temperature range and coefficient of friction. Several brake companies, such as Endless USA, Mintex Racing, and Wilwood, provide pad-specific temperature and friction coefficient data on their Web sites to help you choose the right pads for your application.

The pad's temperature range is just that-the operating temperature at which it provides its optimal grip. If you're looking for a track-day pad with resistance to fade at high temperatures, this is a telling factor. But you need to watch the other end of the range, too, especially if you're upgrading a street car. If you live in Wisconsin and choose a pad that works best between 30 and 700 degrees Fahrenheit, that first stop on a winter morning could be more thrilling than it should be. Temperature range is one of the biggest reasons why you shouldn't run race-level pads on the street.

The pad's other characteristic, friction coefficient, is a good indicator of its initial "bite," said Chen. In general: the higher the number, the stronger the bite. But also pay attention to the pad's coefficient rating range. "Friction coefficient is sort of like a bell curve," he explained. "It's not linear through the temperature range. The first number indicates what the pad's initial bite will be, and the second is what it will top out at, not what it will reach at the end of the range, but the highest it will reach." The narrower the coefficient range, the more consistent, or predictable, the pad's bite will be throughout its temperature range.

Rotor rooting

Combine a pad upgrade with new brake rotors and braking performance takes another jump.

"We talk to people in terms of good/better/best upgrade options," said Stillen's Bernal. "At the 'Good' level we recommend the original calipers with a higher heat-range pad and original-size rotors, but rotors that are heat treated, possibly cross-drilled or drilled and slotted. It's a pretty low budget step up; in some cases it's no more expensive than going to dealer and getting replacement parts there."

The slots in a rotor's face (also called slits by some companies) are there to shave the face of the brake pad, helping to "keep the pad faces free of burnt compound elements and help to prevent pad glazing," said Wilwood's Bush. Added Brembo's Valskis, "Rotor slots can also lead to increased disc life. Because they continuously clean and refresh the brake pad surface, the pads won't harden" and wear the rotor surface.

And then there's rotor cross-drilling, one of the biggest areas of disagreement there is among brake companies. Drilling a rotor was originally intended to lighten it for racing applications, and to provide an outlet for gasses that were vented by certain types of racing brake pads as they got hot. Like slotting, cross-drilling does some pad-face cleaning. Beyond that, the benefits of drilling are hotly contested.

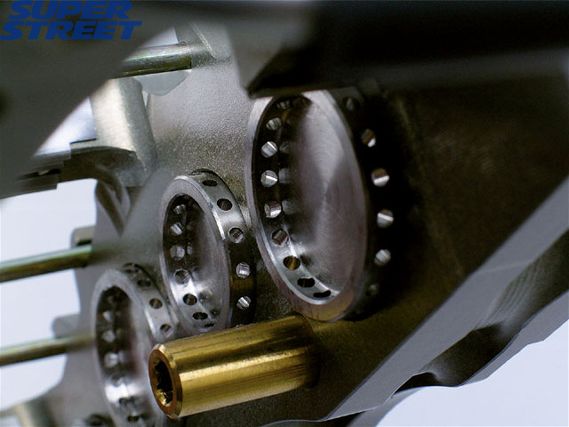

There are, however, other rotor design characteristics that provide definitive performance benefits that all our experts agree on. One is to step up from a one-piece iron rotor to a two-piece rotor with an iron disc that's mated to a hat or bell-which mounts the rotor to the hub-made of a lighter material, such as aluminum. This design reduces the rotor's overall weight, which lightens the car in a critical area, since rotating mass is several times heavier than stationary mass. Using aluminum for the hat also helps protect the wheel hub from heat damage, as aluminum dissipates heat better than iron.

The biggest advantage to a two-piece rotor, though, is that it allows the use of a "floating" hat assembly, where the hat is held to the disc with clips, pins or some other device that allows "movement radially, toward or away from the center, between the hat and rotor, but keeps them fixed in the direction of rotation," said Barnes. "The benefit is that the rotor expands evenly on both sides, rather than taking on a slightly conical shape, as can happen when the friction surface is heated with one side solidly connected to a hat that is at a lower temperature. Rotor coning can lead to uneven pad wear that will prevent a solid pedal feel and confident on/off response."

Improving pad wear, lightening the rotor and reducing the risk of warpage all benefit overall brake performance. But if what you're after is an increase in actual stopping power, there's only one way to take a rotor: bigger.

Of course, rotor size is ultimately limited by wheel size. And there isn't a hard-and-fast rule about how much rotor you can fit behind certain wheel diameters. "In general, a 17-inch wheel will accommodate up to a 332-mm (13.1-inch) rotor, a 355-mm (14.0-inch) rotor will require an 18-inch wheel, and a 380-mm (15.0-inch) rotor needs a 19-inch wheel," said StopTech's Barnes. He was the only one of our experts who would commit to any kind of size estimate.

So how do you figure how large to go with your rotors? Check with your brake retailer first, as he or she may have first-hand experience with your wheel application. If that's not the case, many brake companies offer downloadable templates, made from CAD drawings printed to scale, that you can hold up against| the inside of your wheel to check fit. And remember, like many other performance items,bigger isn't always better when it comes to rotors. "In general, rotor size should be determined by the energy absorption and dissipation requirements the vehicle places on its brake system," said Barnes. "If you choose a rotor larger than is required, its greater mass will make the car slower."

Caliper Clamping

A bigger rotor by itself isn't going to have much of an effect on stopping power. You need to combine that big disc with a caliper that has enough clamping force to haul it down. But do you really need a caliper with six, or even eight, pistons to get the job done?

"You have to match your brake force to your car's horsepower," said Dominic Chen. "Too much force can lock up the wheels and upset brake balance. If you have a brake kit that's too big or weighs a lot, you're not getting the bang for the buck in terms of performance."

"Keep in mind," added Bush, "that the piston volumes within the caliper must remain matched to the volume capacity output of the master cylinder." Translation: If you've gone really big with rotors and calipers, your stock master cylinder may not be pumping enough juice for the pistons in the caliper to achieve their maximum clamping force. You may need a master cylinder upgrade, matched with a brake booster to maintain the level of pedal effort you had prior to the upgrade.

While we're on the subject of fluid, two things: First, there's a reason brake upgrades often include braided-steel brake lines, and it's not just for cosmetic reasons. The rubber hose between your car's stock hard lines and the caliper can swell due to age or because of increased fluid pressure in the lines. That swelling increases pedal travel and makes it feel all soft and spongy. The current generation of high-performance brake lines offers a steel-braided outer cover with a Teflon inner liner, both of which prevent brake line swelling.

Second, not all brake fluids are created equal. Like brake pads, they have operating temperature ranges; in this case, they're classified by their boiling points. These correspond to government labels-the DOT 3, DOT 4, and so on-you find on brake fluid containers. The higher the DOT number, the higher the fluid's boiling point. Why does this matter? Brakes can get hot enough to boil the fluid, particularly if the fluid has absorbed some water over time, which lowers its boiling point; or if you're using a street-oriented fluid under competition conditions. Fluid boiling creates gas bubbles in the brake lines, which result in a soft or spongy pedal.

Upgrading to a higher DOT rating pushes the fluid's boiling point beyond the risk of boiling during hard use. The highest rated fluid you can use, with a DOT 5.1 rating, has a dry boiling point of 509 degrees F, compared to 446 degrees for DOT 4 and 401 for DOT 3. Unfortunately, DOT 5.1 fluids also have retail prices that are several times higher than DOT 4 fluids. Don't confuse a DOT 5.1 fluid with a DOT 5. They have the same dry boiling point, but DOT 5 fluids are silicone based, while DOT 5.1 (as well as DOT 3 and 4) fluids are glycol based. A degree in chemistry would help you sort out the differences; suffice it to say that the silicone-based fluids are more compressible than the glycol-based ones, meaning they'll give you the same spongy pedal feel that glycol fluids exhibit only after boiling.

How often should you change your brake fluid? According to Stillen's Chris Bernal, you shouldn't go longer than two years between flushes "if you're on the street. On the track, probably after every event."

A Matter of Balance

As you look at other modified cars around you, you may notice that some have massive brake upgrades on the front wheels but little, if anything, done to the rears. That can mean that the car builder ran out of money, but it can also indicate a smart buildup plan.

Why? In most cases, a car's front wheels do something on the order of 80 to 85 percent of the braking, largely because of the weight transfer over the front wheels that occurs during deceleration. In a lightweight, front-wheel-drive car, the fronts can do 90 percent, or more, of the braking. That being the case, it makes sense to upgrade the end of the car that's doing the most work. Or, as many of our experts recommended, limit the rear end upgrade to maybe rotors and pads only, to maintain the car's proper brake balance.