| Honda Wheel Fitment Guide - Papa Needs New Shoes

| Honda Wheel Fitment Guide - Papa Needs New Shoes

The wheel dates back to around 4000 B.C when artisans used them for spinning pottery. Later, the Mesopotamians took two discs, stuck one on each end of a hunk of wood and made the world's first axle. Not quite a set of Volks, but we've got to give them props for coming up with the first wheel. The chariot followed, then the underpinnings of an industry yet to be conceived for about another 6,000 years or so. Stuff this old is never simple.

Most know what it takes to bump up horsepower. You wouldn't swap out that set of high-lift, aftermarket cams for some stockers. You wouldn't yank out your Lude's H22A for a beat-down 1.5-liter D-series. Buying a set of wheels shouldn't be any different, that is, if you care about going fast.

Making Them Fit

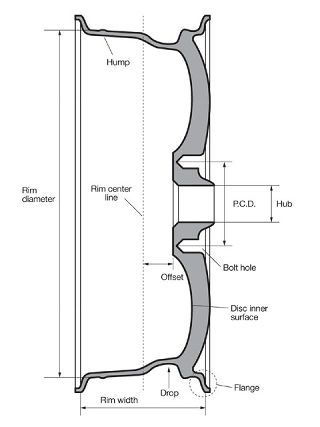

There's more to making a set of wheels fit besides their willingness to be stuffed inside your Civic's fenderwell. Besides the wheel's overall diameter, you need to consider more complicated measurements; some as simple as whether or not they'll bolt to the hub, to trickier matters like how offset changes affect handling.

Bolt Patterns

Bolt pattern is the first thing to check when shopping for wheels. Discerning your bolt pattern is simple: Start by picturing an imaginary circle that passes through the center of each lug. This is the bolt pattern or bolt circle. Most Hondas use a 4x100 bolt pattern: four lugs and 100 millimeters between the center points of any two non-adjacent lugs. For five-lug rims, measure the distance from the center of any hole to the farthest edge of the hole, two spots over.

Centerbores

Hondas, like most OEMs we can think of, use hubcentric wheels. Wheels like these rely on a machined hole on the inside of the wheel that fits snugly over an extruded portion of the hub. This both positions the wheel and takes vertical stresses off the wheel studs unlike older, non-hubcentric wheels which rely on the studs for both positioning and carrying stress loads. If you're fitting aftermarket hubcentric wheels to your Honda, this machined hole is often times larger than what you need due to manufacturing versatility. Make sure to get the right size ring adapter. If you're off even just a bit, your wheels will vibrate worse than a cheap coin-operated bed at Motel 6.

| Honda Wheel Fitment Guide - Papa Needs New Shoes

| Honda Wheel Fitment Guide - Papa Needs New Shoes

Offset

It sounds simple, but offset may be a wheel's most mysterious characteristic. By definition, it is simply the distance from the hub mounting surface to the wheel's centerline. A wheel's offset falls into one of three categories: zero, positive or negative. If you can use a tape measure, you're halfway there. But interpreting the results and understanding why you should care about it requires an explanation.

Offset matters. For one, it determines whether brake calipers, struts, and suspension members will fit behind the wheel. Off by just a few millimeters and those new Brembo calipers might not fit. Off by anymore and the wheel might hit a strut, a shock or not sit on the hub.

Besides fitment issues, offset also affects handling, steering response and ride quality. Offset isn't something you change haphazardly to make a wheel fit. Honda did its homework here, so mess with it at your own peril. Make changes with caution or you may alter the car's scrub radius and worsen torque steer, among other things.

If you're adding a wider wheel, you need less positive offset, meaning the wheel needs to be placed farther out to make clearance. If offset remained the same, then half the extra width of the wheel would be shoved under the fender and most likely hit something. Plan for this ahead of time with some basic calculations on your current rims prior to ordering up some new platters.

Before you can measure your current wheel's offset though, you'll need to figure out its backspace measurement. Lay the wheel flat on the ground, rest a straight edge across its surface and measure the distance between the wheel's hub mounting surface to the straight edge. This is its backspace. Then subtract this number from the wheel's width and divide by two.

A zero offset means the hub mounting surface lines up with the wheel's centerline. A positive offset, like you'll find on front-drive Hondas, means the hub mounting surface lies toward the outside half of the wheel. These push the wheel/tire in closer to the car. Conversely, a negative offset means the hub mounting surface is closer to the brake side of the wheel, and you'll typically find that these suit rear-drive cars, no matter how badly you want some fat-lip deep dishes on your hatch.

There's another easy way to measure offset: flip the wheel over and read the offset number etched in the metal.

Once you know offset, you can calculate what will fit. Measure between the inner sidewall of the tire and the object it comes closest to on the car (shocks or upper control arms, for example). Bearing in mind that half the additional width of the new wheel will go under the fender, if offset remains equal, something will probably hit. To fix this, you'll need to move the wheel out. Either slap on a set of spacers or calculate a reduction in positive offset.

Sizing

Never mind what the car show judges say: smaller wheels are almost always better. They're lighter, allow for better acceleration and handling, and even improve ride quality. Unless the brakes won't fit, 15s usually get the job done for most Honda/Acuras.

Width is different. Wider is better. Wider rims make for a more stable ride, better handling and more responsive steering. Narrow rims don't have much to offer except better ride quality when compared to wider rims. Face it: whether you've got a show queen or a track rat, nobody wants a narrowrim

Clearance

After dealing with the concrete science of bolt patterns and offsets, the trial-and-error process of fitting a wheel inside a fender well is almost refreshing. A lot can change here, including camber as the suspension travels, not to mention the unpredictability of rounded fender lips and the tire's sidewall. This is pretty much a crapshoot.

Fun With Numbers

Most of the time, a set of 15s will give the best acceleration results. But to make sure, you can calculate how any car might be affected when changing wheel and tire sizes. Simply pick an arbitrary MPH number along with its corresponding gear ratio and RPM point, as well as your desired tire height. Drag racers make use of this equation for determining wheel/slick size and gear ratios to make the most out of a pass. To calculate what size tires you'll need, and effectively what wheel you'll want, multiply the proposed MPH by the gear ratio and the constant 336. Divide this by your RPM and you have a good starting point for wheel shopping.

| Honda Wheel Fitment Guide - Papa Needs New Shoes

| Honda Wheel Fitment Guide - Papa Needs New Shoes

Weight

The biggest advantage of smaller wheels is their lighter weight, compared to a dumb set of big-ass chrome dubs. Besides reducing the overall weight of the vehicle, smaller, lighter wheels also reduce unsprung weight, the weight of parts not supported by the springs-including, but not limited to, wheels, tires and brakes. Less unsprung weight translates into better handling and reduced rotational inertia

Like flywheels, cranks, clutches and axles, the lighter the rotating component, the better the acceleration. It works under braking, too. The less rotational mass to halt, the sooner you'll stop.

One-Piece, Two-Piece, Three-Piece

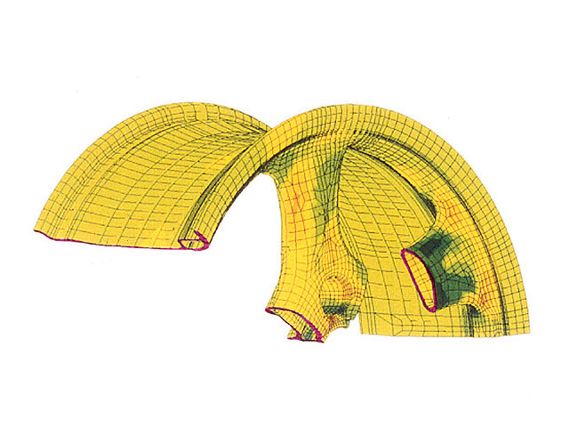

Two or three-piece, split rim, composite, whatever you want to call 'em, wheels like these were first developed in the 1970s. Unlike one-piece wheels, which are cast or forged from a single piece of material, multi-piece rims are constructed of either two or three pieces. Two-piece wheels are made up of a center and an outer section. The two pieces are then welded or bolted together. Three-piece rims are pretty much the same but also include a separate center disc. Wheels like these are almost always more expensive due to elaborate machining processes, as well as the manual labor required to bolt them together

Years back, one-piece forged rims were astronomically expensive-the machining involved was simply too much. Matching a forged centerpiece to a spun aluminum outer ring was a less costly alternative, hence the introduction of the two-piece wheel. Rims like these could be manufactured cheaper, were lightweight and offered flexibility and repair options far superior to their one-piece counterparts

Today, the cost issues are less significant but the flexibility of the multi-piece rim still rings true. Varying offsets, centerbores and bolt patterns can be offered simply by manufacturing a number of different center sections. Still, if weight is your main concern, it's tough to beat a good old-fashioned one-piece rim. Because they lack bolts, flanges and other structural considerations required to mate the separate pieces tighter, one-piece rims are often lighter.

| Honda Wheel Fitment Guide - Papa Needs New Shoes

| Honda Wheel Fitment Guide - Papa Needs New Shoes

Materials And Manufacturing

Besides fitment, weight and size issues, you're faced with a few choices when it comes to wheel metal. A wheel's material construction affects overall and unsprung weight, effectiveness under braking and the rigidity of the wheel itself. You've got two choices here: alloy or steel.

If you care about going fast, alloy is your only choice. Aluminum alloys are more rigid than steel and won't flinch even under extreme lateral stresses. They also conduct heat better, dissipating high temps from your brakes to reduce brake fade.

Wheel manufacturing also matters. The two most popular methods are casting and forging. Casting, in its simplest form, involves dumping molten metal into a mold. But there's more than one way to get it done. Gravity casting is the cheapest and still a common method. Here, liquid metal fills the mold to the extent that gravity will allow it. Wheels like these are almost always the heaviest.

| Honda Wheel Fitment Guide - Papa Needs New Shoes

| Honda Wheel Fitment Guide - Papa Needs New Shoes

Low-pressure casting is similar but relies on pressure to pack the metal into the mold. The result is a denser, yet lighter rim. Finally, the spun rim casting method also relies on pressure to pack the mold, but spins the casting in the process. The outer portion is heated and the metal is shaped during the process. This is about as close as you'll get to a forged-quality wheel without the high cost. A properly cast wheel will provide years of service, but will never match the quality of a forged unit. It's impossible to pack the molecules as tight when casting. The sloppier the casting process, the more likely molecular gaps, which lead to cracking, are to appear within the metal.

When it comes to forging, one-piece rims don't get any better than this. Their strength-to-weight properties are second to none. In comparison to cast wheels, the forging process packs the molecules tight enough to not allow space in between the metal. This is achieved by compressing billet aluminum with heat and several million pounds of pressure, strengthening the molecular bonds and turning out a solid, strong piece of aluminum alloy. All the benefits of this cool technology come at a price, however.

Just as we like to rotate and refresh our sneaks locker, we're all for changing up our wheels occasionally. But if you're after functionality first, fashion second, choosing the right wheel is anything but simple. With material choices, weights, offsets and sizes, choosing the best rolling stock for your ride requires more careful consideration than just JDM street cred.