It's been called weak by sled pullers and off-roaders. It's been called complicated by Dodge and Ford owners. And it's been ridiculed since GM replaced its Dana 60 front axle with it for the '88 model year. We're talking about GM's independent front suspension (IFS). And while it is more complex than the solid axles Dodge and Ford use, this is 2011-and there are fixes for everything.

| 1103dp 2001 To 2010 Gm Frontend Fortification gmc Sierra Front Shot

If the last five years of diesel motorsports have proven anything, it's that the front suspension under the Duramax is capable of harnessing and handling big horsepower. With the right parts, boosted launches at the dragstrip and full pulls on the dirt are easy to come by. In the following pages, we'll show you how to make your '01 to '10 Chevy or GMC frontend stand up to all the horsepower the Duramax can create. Whether you're a weekend warrior, an all-out competitor, or you drive a hot street truck, we'll give you a recipe to make your 91/4-inch-diameter ring gear AAM IFS bulletproof.

Power To The Ground

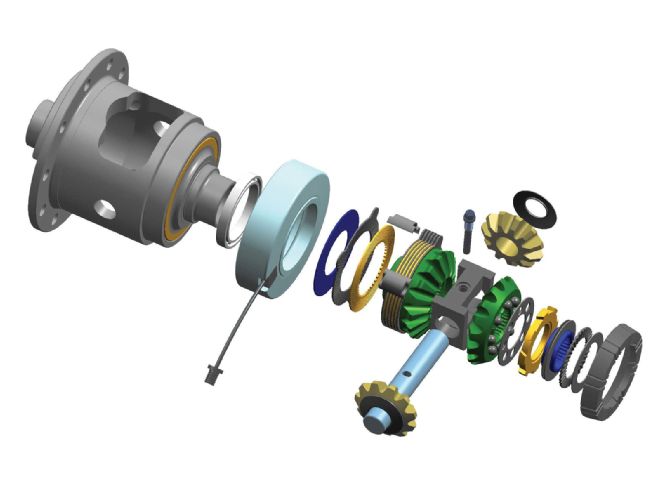

The axles (also known as halfshafts, or CV-shafts) in GM's independent front suspension transmit power from the front differential to the front wheels. The halfshafts use constant-velocity (CV) joints to transmit the torque, while still allowing for steering and suspension movements. There are a total of four joints in the GM frontend. The inner joints (A) are called tripod joints. They handle changes in angle and axle plunge to compensate for the suspension travel. The outer CVs (B) use six-ball Rzeppa joints, which are capable of handling more angle (for the steering) and do not plunge.

| 1103dp 2001 To 2010 Gm Frontend Fortification gm Halfshafts

The Key To IFS Durability

Everything in the GM IFS frontend is at its strongest when it is working in a straight line. The less angle the CV-shafts, steering links, and ball joints are exposed to-the stronger this frontend is. Ideally, you want to tune the truck's ride height to make the CV-shafts and tie rods parallel whenever the truck is putting the most power down. This will allow your truck to be more capable off-road, survive a sled pull, and launch successfully in four-wheel drive on the pavement.

Hot Street Setup

(and occasional sled puller):

- Heavy-duty tie-rod sleeves

- Pitman and idler arm braces

- Do not lift the ride height of the front suspension

| You might remember this truck from the Oct. '10 issue ("Hoosier State Showdown"). Ryan Lorentz's LMM-powered Silverado was equipped with green torsion bar keys, and because he pulls in a Work Stock Class, he couldn't utilize front-hanging weights. When he began this pull, the weight of the sled on the rear of the truck unloaded the front suspension greatly. This resulted in the CV joints trying to do their job at an odd angle, and severe tire toe-in occurred as the tie rods flexed. According to the experts at Fleece Performance, if you're running green torsion bar keys, hanging weight is essential for sled pulling.

Hot Street Setup/Drag Racer (500 to 650 hp):

- Heavy-duty tie-rod sleeves

- Lower the front suspension

- Run purple torsion bar keys

| Tyler Upton's bracket-racing, '05 Sierra has made countless dragstrip passes at its current, 552-rwhp level. To date, the frontend has given him zero problems, and his suspension setup only called for adding heavy-duty tie-rod sleeves and keeping the front suspension as low as possible.

Drag Race Setup (650 hp and up):

- Straight centerlink, or stabilizer bracket for stock centerlink

- Heavy-duty tie-rod sleeves

- Lower the front suspension

- Run purple torsion bar keys

Sled Pull Setup (2.6 Class and up):

- Aftermarket tie rods

- Pitman and idler arm braces

- Straight centerlink, or stabilizer bracket for stock centerlink

- Lower the front suspension

- Run purple torsion bar keys (or machined keys for an even lower stance)

- Install a locker in the front differential

- Chromoly axleshafts (optional)

- Chromoly CV joints (optional)

| Matt Sparkman's 2.6 Class sled puller is an accurate example of the recipe listed here. Between the 1,700 lb-ft of torque (not to mention gear reduction) making its way to the ground and having more than 1,000 pounds of weight hovering out in front of the axle, the frontend is under a lot of stress in an extreme application. The above setup is a bulletproof recommendation for sled pullers making up to 850 hp at the wheels-and it may even survive more horsepower than that.