Welding 101: Part II

| 0502mt Weld01 Z

In Part I of our welding series, we introduced the MIG-welding setup and basics, along with the chance to win a Miller welding helmet. We also gave you a good foundation to begin learning how to weld on your own truck. This time around, we figured we would build on the knowledge already presented and go a little deeper. We tackled the issues of welding tubing, steel pieces of various thicknesses, and sheetmetal together. We also tried welding in different positions to simulate actual working conditions.

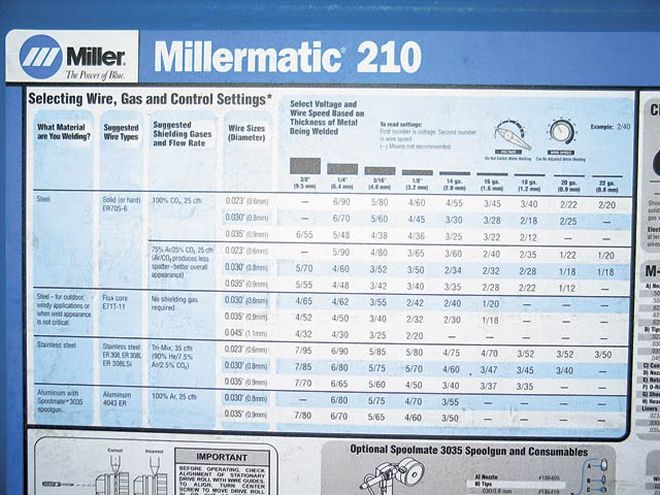

Using what you learned in the first story (and if you've been practicing your technique), you can move ahead and begin welding tubing together for your bridge, a four-link, or just to make a cool desk. When working on mini-trucks, tubing is a fabricator's best friend. It can be bent and welded in any manner to fit a specific suspension, fuel-cell mounting, interior piece, or anything that you need to make work and look good. Once Mike Alexander became a little more comfortable welding the tubing, it was time to move on to another MIG-welding challenge: welding steel pieces of different thicknesses together. For this task, the tricks are definitely speed, technique, and the voltage setting.

With Mike becoming a more proficient welder, it was time to put him to the test one last time by attacking some sheetmetal work. Welding sheetmetal is also fairly tricky because if your settings are off or you move too slowly or too fast, you risk burning through the metal or warping it. This is an excellent skill to practice, as it will come in handy when the time comes to shave those door handles or anything else you want to permanently remove from the exterior of your truck.

Check out all these techniques and add them to your welding-knowledge arsenal. If you're serious about developing this important fabrication skill, it might also be a good idea to pick up some reading material, videos, or whatever method you learn best from at your local welding supply store. Once you've mastered welding tubing, different-thickness metals, and sheetmetal, and welding in uncomfortable positions, you'll be on your way to building the mini-truck you've always envisioned. For more information, refer to the source box.

| 0502mt Weld01 Z

In Part I of our welding series, we introduced the MIG-welding setup and basics, along with the chance to win a Miller welding helmet. We also gave you a good foundation to begin learning how to weld on your own truck. This time around, we figured we would build on the knowledge already presented and go a little deeper. We tackled the issues of welding tubing, steel pieces of various thicknesses, and sheetmetal together. We also tried welding in different positions to simulate actual working conditions.

Using what you learned in the first story (and if you've been practicing your technique), you can move ahead and begin welding tubing together for your bridge, a four-link, or just to make a cool desk. When working on mini-trucks, tubing is a fabricator's best friend. It can be bent and welded in any manner to fit a specific suspension, fuel-cell mounting, interior piece, or anything that you need to make work and look good. Once Mike Alexander became a little more comfortable welding the tubing, it was time to move on to another MIG-welding challenge: welding steel pieces of different thicknesses together. For this task, the tricks are definitely speed, technique, and the voltage setting.

With Mike becoming a more proficient welder, it was time to put him to the test one last time by attacking some sheetmetal work. Welding sheetmetal is also fairly tricky because if your settings are off or you move too slowly or too fast, you risk burning through the metal or warping it. This is an excellent skill to practice, as it will come in handy when the time comes to shave those door handles or anything else you want to permanently remove from the exterior of your truck.

Check out all these techniques and add them to your welding-knowledge arsenal. If you're serious about developing this important fabrication skill, it might also be a good idea to pick up some reading material, videos, or whatever method you learn best from at your local welding supply store. Once you've mastered welding tubing, different-thickness metals, and sheetmetal, and welding in uncomfortable positions, you'll be on your way to building the mini-truck you've always envisioned. For more information, refer to the source box.

| 0502mt Weld01 Z

In Part I of our welding series, we introduced the MIG-welding setup and basics, along with the chance to win a Miller welding helmet. We also gave you a good foundation to begin learning how to weld on your own truck. This time around, we figured we would build on the knowledge already presented and go a little deeper. We tackled the issues of welding tubing, steel pieces of various thicknesses, and sheetmetal together. We also tried welding in different positions to simulate actual working conditions.

Using what you learned in the first story (and if you've been practicing your technique), you can move ahead and begin welding tubing together for your bridge, a four-link, or just to make a cool desk. When working on mini-trucks, tubing is a fabricator's best friend. It can be bent and welded in any manner to fit a specific suspension, fuel-cell mounting, interior piece, or anything that you need to make work and look good. Once Mike Alexander became a little more comfortable welding the tubing, it was time to move on to another MIG-welding challenge: welding steel pieces of different thicknesses together. For this task, the tricks are definitely speed, technique, and the voltage setting.

With Mike becoming a more proficient welder, it was time to put him to the test one last time by attacking some sheetmetal work. Welding sheetmetal is also fairly tricky because if your settings are off or you move too slowly or too fast, you risk burning through the metal or warping it. This is an excellent skill to practice, as it will come in handy when the time comes to shave those door handles or anything else you want to permanently remove from the exterior of your truck.

Check out all these techniques and add them to your welding-knowledge arsenal. If you're serious about developing this important fabrication skill, it might also be a good idea to pick up some reading material, videos, or whatever method you learn best from at your local welding supply store. Once you've mastered welding tubing, different-thickness metals, and sheetmetal, and welding in uncomfortable positions, you'll be on your way to building the mini-truck you've always envisioned. For more information, refer to the source box.