1993 Custom Toyota Mini Truck - Project Dragged Daily: Part III

| 1993 Custom Toyota Mini Truck Suspension rear Finished

The mini-truckin' scene is an ever-evolving world of heavily modified custom trucks that constantly push the boundaries of customization. The mini-truckers of today outdo themselves every single time they put a welder to the metal. Since we, Mini Truckin' magazine, strive to bring you the most hard-core, best of the best in the mini-truck scene, why not do something completely different with our own project truck? We've already showed you the buildup of the highly unique framerails and control arms, and for Part III of the build, we're getting even crazier and diving into the independent rearend install.

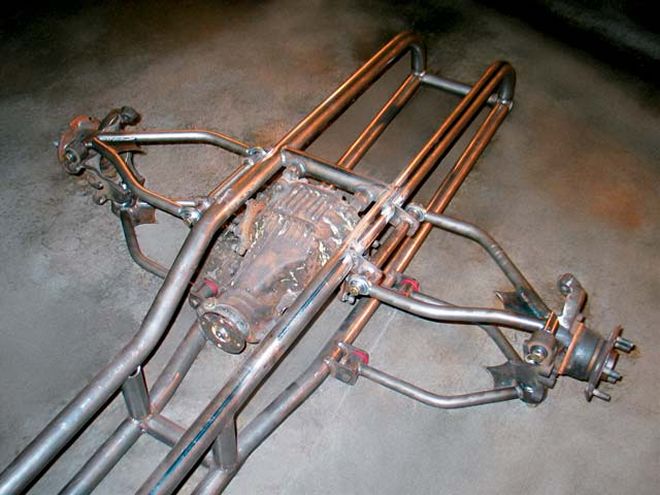

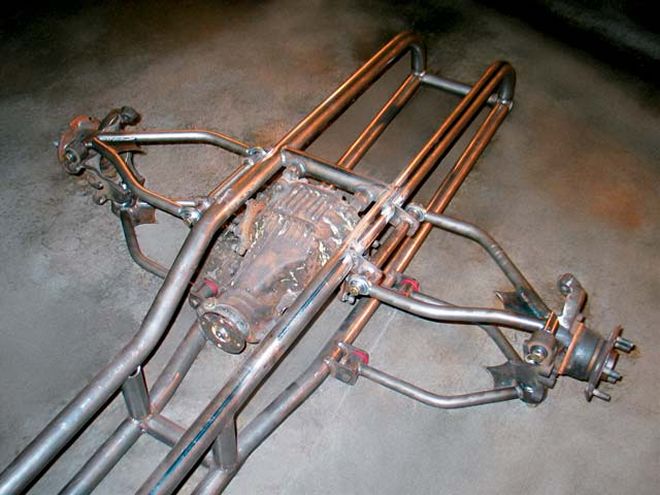

When Aaron Iha and I sat down to design a truly one-of-a-kind chassis for MT's 'Yota project, we decided that a '90 Toyota Supra Independent rearend would be the way to go. This independent rear gave us the freedom to build the narrow chassis we were after and flows perfectly with the drivetrain, because we could solidly mount the differential inside the narrow tubular framerails. We also chose this particular rearend because of the insane first-ever air-adjustable coilover suspension setup that we'll bring you in the upcoming months. We knew that the Supra rear would need to be shortened, so that's where we started.

After taking a few measurements, we called up Dutchman Motorsports in Portland, Oregon, to do the deed. To fit the wheels underneath the Toyota bed, each side needed to be shortened about 2 inches. However, with the 19x10-inch Boyd wheel, we wanted to run a 6-inch backspace; that way, we would at least have some kind of lip on the wheel, since most import trucks are forced to run FWD rims. This meant we would need to take 3-3/4 inches off each side, but you can't shorten the shafts that much, so we had to have new shafts built to our exact specifications.

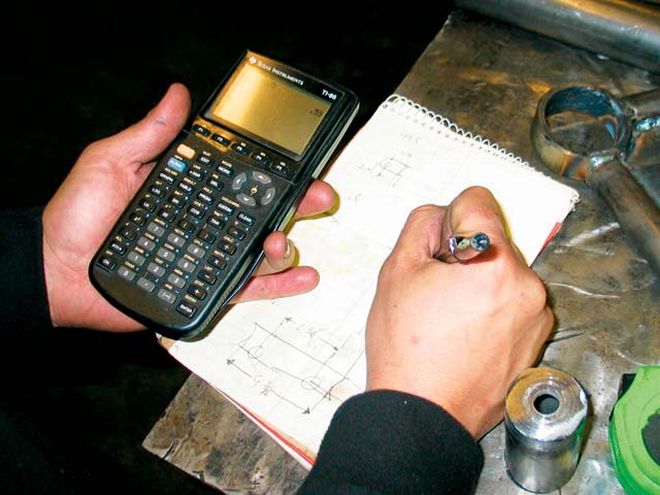

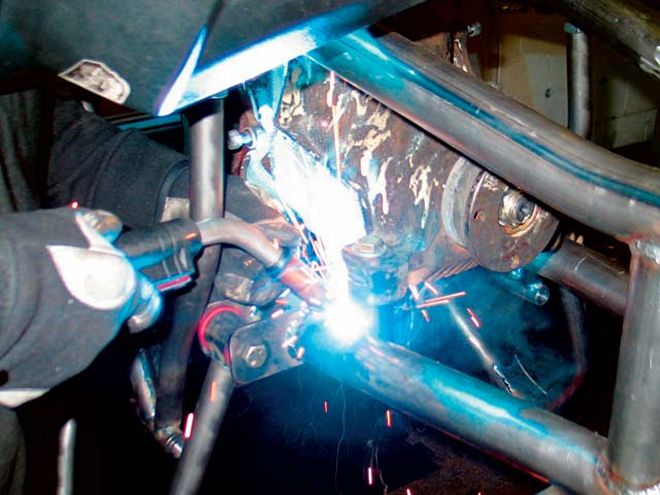

To mount the diff, there was no need for Aaron to spend countless hours designing mounting points or do any of his "crazy engineering stuff," because after a couple quick measurements and a few plugs on his handy-dandy nerdilator (TI-85 calculator), he was ready to get to work. There's no trick or fancy system, just good old-fashioned tubing, a chop saw, and a welder. Since the rear can be solidly mounted, as long as every thing is double-checked for clearance (especially the driveline), the rest is pretty simple. Follow along to see our 'Yota that much closer to completion. For more information, contact the companies listed in the source box.

| 1993 Custom Toyota Mini Truck Suspension rear Finished

The mini-truckin' scene is an ever-evolving world of heavily modified custom trucks that constantly push the boundaries of customization. The mini-truckers of today outdo themselves every single time they put a welder to the metal. Since we, Mini Truckin' magazine, strive to bring you the most hard-core, best of the best in the mini-truck scene, why not do something completely different with our own project truck? We've already showed you the buildup of the highly unique framerails and control arms, and for Part III of the build, we're getting even crazier and diving into the independent rearend install.

When Aaron Iha and I sat down to design a truly one-of-a-kind chassis for MT's 'Yota project, we decided that a '90 Toyota Supra Independent rearend would be the way to go. This independent rear gave us the freedom to build the narrow chassis we were after and flows perfectly with the drivetrain, because we could solidly mount the differential inside the narrow tubular framerails. We also chose this particular rearend because of the insane first-ever air-adjustable coilover suspension setup that we'll bring you in the upcoming months. We knew that the Supra rear would need to be shortened, so that's where we started.

After taking a few measurements, we called up Dutchman Motorsports in Portland, Oregon, to do the deed. To fit the wheels underneath the Toyota bed, each side needed to be shortened about 2 inches. However, with the 19x10-inch Boyd wheel, we wanted to run a 6-inch backspace; that way, we would at least have some kind of lip on the wheel, since most import trucks are forced to run FWD rims. This meant we would need to take 3-3/4 inches off each side, but you can't shorten the shafts that much, so we had to have new shafts built to our exact specifications.

To mount the diff, there was no need for Aaron to spend countless hours designing mounting points or do any of his "crazy engineering stuff," because after a couple quick measurements and a few plugs on his handy-dandy nerdilator (TI-85 calculator), he was ready to get to work. There's no trick or fancy system, just good old-fashioned tubing, a chop saw, and a welder. Since the rear can be solidly mounted, as long as every thing is double-checked for clearance (especially the driveline), the rest is pretty simple. Follow along to see our 'Yota that much closer to completion. For more information, contact the companies listed in the source box.

| 1993 Custom Toyota Mini Truck Suspension rear Finished

The mini-truckin' scene is an ever-evolving world of heavily modified custom trucks that constantly push the boundaries of customization. The mini-truckers of today outdo themselves every single time they put a welder to the metal. Since we, Mini Truckin' magazine, strive to bring you the most hard-core, best of the best in the mini-truck scene, why not do something completely different with our own project truck? We've already showed you the buildup of the highly unique framerails and control arms, and for Part III of the build, we're getting even crazier and diving into the independent rearend install.

When Aaron Iha and I sat down to design a truly one-of-a-kind chassis for MT's 'Yota project, we decided that a '90 Toyota Supra Independent rearend would be the way to go. This independent rear gave us the freedom to build the narrow chassis we were after and flows perfectly with the drivetrain, because we could solidly mount the differential inside the narrow tubular framerails. We also chose this particular rearend because of the insane first-ever air-adjustable coilover suspension setup that we'll bring you in the upcoming months. We knew that the Supra rear would need to be shortened, so that's where we started.

After taking a few measurements, we called up Dutchman Motorsports in Portland, Oregon, to do the deed. To fit the wheels underneath the Toyota bed, each side needed to be shortened about 2 inches. However, with the 19x10-inch Boyd wheel, we wanted to run a 6-inch backspace; that way, we would at least have some kind of lip on the wheel, since most import trucks are forced to run FWD rims. This meant we would need to take 3-3/4 inches off each side, but you can't shorten the shafts that much, so we had to have new shafts built to our exact specifications.

To mount the diff, there was no need for Aaron to spend countless hours designing mounting points or do any of his "crazy engineering stuff," because after a couple quick measurements and a few plugs on his handy-dandy nerdilator (TI-85 calculator), he was ready to get to work. There's no trick or fancy system, just good old-fashioned tubing, a chop saw, and a welder. Since the rear can be solidly mounted, as long as every thing is double-checked for clearance (especially the driveline), the rest is pretty simple. Follow along to see our 'Yota that much closer to completion. For more information, contact the companies listed in the source box.