People have been riding on air since John Dunlop invented the pneumatic tire in 1887. The average motorist might think that his tires’ rubber and steel belts support the vehicles’ weight, but air pressure actually carries the load.

The greater the tire’s internal air volume, the more weight it can theoretically support. But bigger doesn’t always mean greater load capacity. Keep reading to find out why.

The goal here is help you match the tire’s load-carrying capacity (LCC) to your vehicle, particularly for hauling and towing. Dennis “Doctor Tire” Franklin, a longtime tire-retailer trainer, consultant to Interco, and a second-generation tire scholar (his dad designed the original light-truck flotation tire, the Armstrong Tru-Trac), helped us debunk common misconceptions about load ranges and carrying capacities. The focus here is on trucks that have single rear tires.

The Three Rules

1. A tire’s LCC is determined by its operating temperature.

2. The higher the speed, the more heat—and the lower the LCC.

3. Weight also increases heat, decreasing LCC.

| Factory Tire Rating And Pressure Chart

Construction Considerations

Logic suggests that the tire’s internal air volume is always proportional to its LCC. This isn’t necessarily the case. Tire construction affects heat generation and dissipation, which determines operating temperature, which establishes LCC. (A tire’s normal highway operating temperature is up to 200 degrees F.)

When comparing tires that are the same size/same internal static air volume but have different load ranges, one with a higher load range at higher air pressures actually may have a lower LCC. For example, a P275/65R18 can have a 2,500-pound maximum LCC at 35 psi, whereas an LT275/65R18/C (six-ply rated) might only have a 1,948-pound capacity at its maximum 50 psi. The difference:

P versus

LT.

“The only things P-metric and LT tires have in common is that they’re black and round,” Dennis Franklin says. “LT fitments have more rubber: heavier plies, a deeper tread, and a stronger bead bundle. More rubber means greater weight or mass, which generates and retains more heat.” See Rule 1 above.

The LT designations (LT-metric, LT-flotation, and LT-numeric) all carry load ratings. The maximum load, designated by a load range letter, is molded into the tire’s sidewall. In contrast, P-metric sizes aren’t load-rated. The tire industry has established that, when used in light-truck applications, P-metric sizes lose 9 percent of their LCC (0.909 to be exact). An example using a common F-150 OE fitment:

P255/65R17 = max 2,205 lb @ 35 psi (sidewall rating) x 0.909 = 2,004 lb actual LCC on a light-truck

As a safety margin, an additional 20 percent reserve load capacity is deducted from all tires to determine the constant working load (WL). Using the 255/65R17LT example above:

2,004 lb x 0.80 = 1,606 lb WL x 2 tires = 3,206 lb per axle

Deduct the approximately 1,800 pounds the F-150 rearend weighs from the tires’ 3,206-pound WL capacity. That leaves 1,406 pounds of combined rear towing/hauling weight that this truck can safely, constantly support at its 35 psi recommended maximum inflation up to its maximum rated speed.

| Sidewall specs indicate a maximum load of 3,000 pounds at 50 psi, 105 pounds under OE rear weight-carrying spec. The tire’s Service Description code is to the left of the Load Range: Load Index (199 = 2,998 pounds) and Speed Rating (Q = 99 mph).

Load Range: LT-Metric Vs. LT-Flotation Vs. LT-Numeric

A tire’s load range letter is an attempt to equate radial tires’ carrying strength in old bias-ply terms. Air pressure is the functional indicator: Higher-load tires accept higher maximum pressures. Also, a single mono steel ply, or one-ply, is stronger than multiple cotton-cord plies from the early bias-ply days. Further, a single steel ply can actually support more weight than multiple plies; less mass and less friction means less heat, ergo greater load capacity.

Wheelers often wonder why some mud-tire sizes aren’t available in Load Range E. The answer is tire construction. Flotation sizes have even more mass and softer sidewalls than the often-narrower closest LT-metric or LT-numeric sizes, so they generate and retain more heat.

Flotation tires are built to flex—great for conforming to uneven terrain, but less stable when supporting loads on the road. They require higher air pressure than LT fitments to support comparable weight. This torpedoes the flotational philosophy of airing down for a wide, amoeboid footprint.

Borrowing an example from Toyo’s catalog, an ’06 HUMMER H2 with an OE LT315/70R17 has a maximum LCC of 2,595 pounds at 37 psi per tire. For a “plus 0” (same wheel diameter) swap to a 35x12.50R17 flotation tire, the industry-standard TRA Load & Inflation Table (available on Toyo’s and other tire manufacturers’ websites) helps determine proper air pressure for the required LCC. According to the table, the 35x12.50R17 supports 2,581 pounds at 39 psi (slightly under OE spec), so the table-recommended pressure is 40 psi—good for 2,625 pounds.

Further, the smaller the sidewall’s static load radius (measured from the axle’s center to the ground), the greater its load-carrying capacity. Low-profile sports car tires corner flat. Similarly, an LT-metric truck tire on a “plus size” 20-inch wheel has less mass, dissipates heat better, accepts higher pressure, and has a higher LCC than a same-diameter, same-width tire on a 17-inch wheel. Flotation-tire sidewall flex comes at the expense of strength and LCC. Wider wheels also increase the functional LCC by stiffening the sidewalls, allowing for a cooler running assembly.

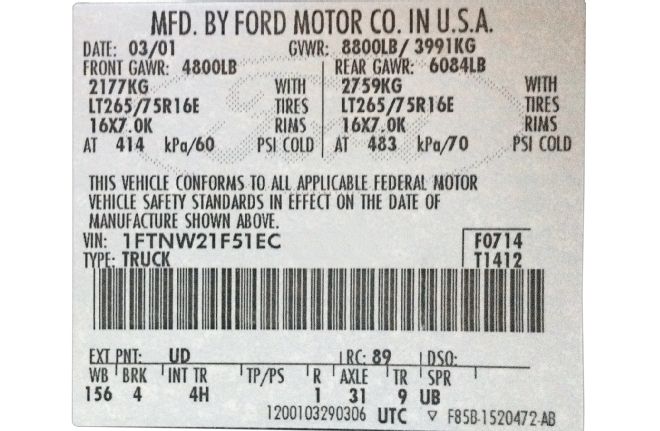

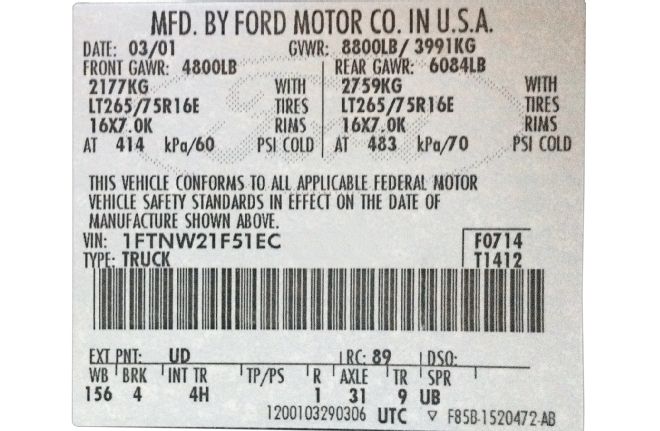

| This ’01 Power Stroke F-250 sometimes carries a 2,500-pound Lance slide-in camper. Tow-alongs add 500 pounds of tongue weight to the rear. The Super Duty’s Tire Information Placard (TIP) shows OE LT265/75R16 “E” range tires. According to the Load Index & Inflation Table, maximum loads are 2,625 pounds front at 60 psi, 3,105 rear at 70 psi. The Super Duty’s current 35x12.50R17 Mickey Thompson Baja ATZs are Load Range D. Many 4x4 owners choose replacement tires based on size, price, and style.

Other Considerations

Unless they’re stripping down for competition, 4-wheelers generally add weight to their vehicles. Thus, the load capacities of aftermarket tires should exceed the OE ratings for the application. Every tire’s sidewall includes a Service Description code that refers to the Load Index & Speed Rating. These specs indicate the fastest speed that the tire can safely support the specified weight.

Knowing your vehicle’s actual “wet”/loaded weights front and rear is the first step for selecting the best tire for the job. (The weight at each end of Ford and Dodge/Ram trucks can be ballparked by multiplying the OE tire’s combined max LCC by 0.75.)

Make sure that all tires under consideration are equal to or exceed the OE load specs, usually published on the Tire Information Placard (TIP) on the doorjamb for newer vehicles. If you’re actually considering “P” or standard load replacement tires, apply the above 0.909 constant load and 0.80 working load fudge factors to identify tires that have the appropriate load index.

| According to the TIP, the front GAWR, which is the maximum weight the axle can support, is 4,800 pounds. So, each front tire needs to support 2,400 pounds plus ideally a 20 percent WL buffer (that’s another 480 pounds per tire, or 2,880 total), to safely run the maximum load at 65 mph. The Load Index & Inflation Table calls for 2,904 at 47 psi. Once front pressure is established, measure from the top of the rim to the ground.

Air Pressure

Handling and control are crucial, particularly on-road. Proper air pressure creates the largest possible contact patch on the ground, maximizing control—especially braking. On bias-ply tires, make a chalk line across the tread, roll the vehicle one revolution on concrete, and adjust pressure until the chalk wears evenly across the tire.

Compared to bias-plies, radials conform more evenly to the road when over- or underinflated. Finding their optimal air pressures is more complicated. Start with the vehicle manufacturer’s recommended pressure, which you will find in the owner’s manual or on the doorjamb.

The Load & Inflation Table will help fine-tune proper pressure based on tire size and the vehicle’s gross combined weight with the necessary WL 20 percent reserve margin. When in doubt, always err on the side of overinflating (less heat). Steering is crisper due to slightly stiffer sidewalls; cornering and braking may not be as stable, and the tires will wear faster. But overall, overinflated tires are safer than underinflated ones.

If the vehicle will be traveling 65-plus mph on LT-metric tires, add 10 psi above the recommended pressure (never exceeding the maximum pressure on the sidewall) for the given load.

Once the baseline pressure is established, rear-tire psi can be fine-tuned for towing/hauling. The time-honored tape-measure method: With the vehicle on level ground, measure the front from the top of a rim to the ground. Adjust rear pressure until a rear rim-to-ground measurement is 3⁄16 inch higher than the front distance. This ensures control and stability of the load. If this difference isn’t possible, then the vehicle is likely too heavy to comfortably control the load, or the front tires are possibly overinflated.

| Take a comparison measurement on a rear tire. For towing or hauling, adjust rear pressure, not exceeding maximum pressure, so that the rim-to-ground height is 3⁄16 inch greater than the front. With camper and trailer tongue weight, we estimated this Super Duty’s rear load at 7,563 pounds, or 3,782 per tire (not including any gear in the camper). An LT-metric tire would be better suited for towing/hauling here and would likely increase fuel economy by as much as 1.5 mpg due to less rolling resistance. A “plus zero” swap to LT325/70R17s would only raise LCC from the current 3,000 pounds to 3,195 per tire. A better comparable-height tire would be LT325/60R20/E. It has a 3,750-pound load capacity at 65 psi.

Off-Road PSI

Proper on-road pressure serves as a starting point for safe off-road airing down. Underinflating generates more heat, so running half of the on-road pressure allows running at approximately half the safe on-road speed without risking heat-related tire failure. Handling and response are obviously slower at lower pressures, though.

Finally, check your wheel’s ratings. Make sure that the tire’s LCC and maximum air pressure fall within the wheel’s specs.

To summarize, know the combined weights of your fully loaded vehicle and trailer tongue (if you tow). Multiply the maximum load rating printed on the tire’s sidewall by four tires, then deduct the 20 percent WL safety margin. If this number is less than the truck and trailer’s combined load, you’re risking heat-related tire failure.

These facts will hopefully help 4-wheelers give their vehicles the necessary support. Of course, this will all change if and when airless tires replace pneumatic ones.

Light Truck & Trailer Tire Load Ratings

Load Max Press. Range (PSI)

B 35

C 50

D 65

E 80

F 95

Tire Speed Ratings

Letter MPH

P 93

Q 99

R 106

| Factory Tire Rating And Pressure Chart

Construction Considerations

| Factory Tire Rating And Pressure Chart

Construction Considerations | Sidewall specs indicate a maximum load of 3,000 pounds at 50 psi, 105 pounds under OE rear weight-carrying spec. The tire’s Service Description code is to the left of the Load Range: Load Index (199 = 2,998 pounds) and Speed Rating (Q = 99 mph).

Load Range: LT-Metric Vs. LT-Flotation Vs. LT-Numeric

| Sidewall specs indicate a maximum load of 3,000 pounds at 50 psi, 105 pounds under OE rear weight-carrying spec. The tire’s Service Description code is to the left of the Load Range: Load Index (199 = 2,998 pounds) and Speed Rating (Q = 99 mph).

Load Range: LT-Metric Vs. LT-Flotation Vs. LT-Numeric | This ’01 Power Stroke F-250 sometimes carries a 2,500-pound Lance slide-in camper. Tow-alongs add 500 pounds of tongue weight to the rear. The Super Duty’s Tire Information Placard (TIP) shows OE LT265/75R16 “E” range tires. According to the Load Index & Inflation Table, maximum loads are 2,625 pounds front at 60 psi, 3,105 rear at 70 psi. The Super Duty’s current 35x12.50R17 Mickey Thompson Baja ATZs are Load Range D. Many 4x4 owners choose replacement tires based on size, price, and style.

Other Considerations

| This ’01 Power Stroke F-250 sometimes carries a 2,500-pound Lance slide-in camper. Tow-alongs add 500 pounds of tongue weight to the rear. The Super Duty’s Tire Information Placard (TIP) shows OE LT265/75R16 “E” range tires. According to the Load Index & Inflation Table, maximum loads are 2,625 pounds front at 60 psi, 3,105 rear at 70 psi. The Super Duty’s current 35x12.50R17 Mickey Thompson Baja ATZs are Load Range D. Many 4x4 owners choose replacement tires based on size, price, and style.

Other Considerations | According to the TIP, the front GAWR, which is the maximum weight the axle can support, is 4,800 pounds. So, each front tire needs to support 2,400 pounds plus ideally a 20 percent WL buffer (that’s another 480 pounds per tire, or 2,880 total), to safely run the maximum load at 65 mph. The Load Index & Inflation Table calls for 2,904 at 47 psi. Once front pressure is established, measure from the top of the rim to the ground.

Air Pressure

| According to the TIP, the front GAWR, which is the maximum weight the axle can support, is 4,800 pounds. So, each front tire needs to support 2,400 pounds plus ideally a 20 percent WL buffer (that’s another 480 pounds per tire, or 2,880 total), to safely run the maximum load at 65 mph. The Load Index & Inflation Table calls for 2,904 at 47 psi. Once front pressure is established, measure from the top of the rim to the ground.

Air Pressure | Take a comparison measurement on a rear tire. For towing or hauling, adjust rear pressure, not exceeding maximum pressure, so that the rim-to-ground height is 3⁄16 inch greater than the front. With camper and trailer tongue weight, we estimated this Super Duty’s rear load at 7,563 pounds, or 3,782 per tire (not including any gear in the camper). An LT-metric tire would be better suited for towing/hauling here and would likely increase fuel economy by as much as 1.5 mpg due to less rolling resistance. A “plus zero” swap to LT325/70R17s would only raise LCC from the current 3,000 pounds to 3,195 per tire. A better comparable-height tire would be LT325/60R20/E. It has a 3,750-pound load capacity at 65 psi.

Off-Road PSI

| Take a comparison measurement on a rear tire. For towing or hauling, adjust rear pressure, not exceeding maximum pressure, so that the rim-to-ground height is 3⁄16 inch greater than the front. With camper and trailer tongue weight, we estimated this Super Duty’s rear load at 7,563 pounds, or 3,782 per tire (not including any gear in the camper). An LT-metric tire would be better suited for towing/hauling here and would likely increase fuel economy by as much as 1.5 mpg due to less rolling resistance. A “plus zero” swap to LT325/70R17s would only raise LCC from the current 3,000 pounds to 3,195 per tire. A better comparable-height tire would be LT325/60R20/E. It has a 3,750-pound load capacity at 65 psi.

Off-Road PSI