| plasma Arc Cutting And Welding girl And Plasma Cutter

We wanted to follow up our welding series with some more helpful fabrication tips that any mini-trucker could use. Since this happens to be the first-ever Chicks Special in the history of any custom-truck magazine, what better way to learn a few things about plasma cutting then to have some ladies on hand to actually demonstrate as we learn? We figured you wouldn't mind.

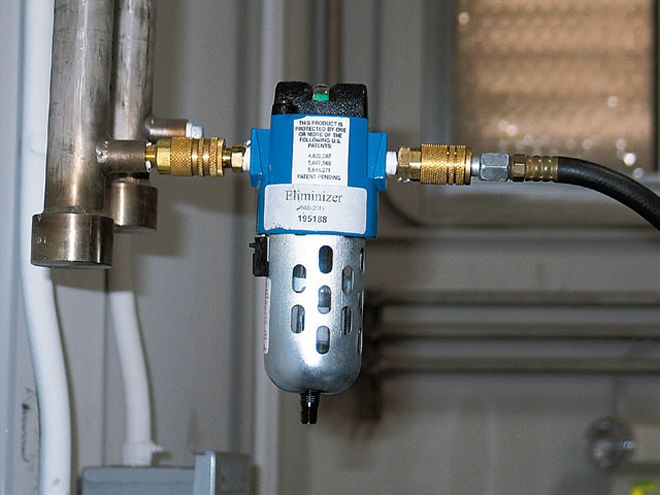

To understand the basics of plasma arc cutting (PAC), let's take a closer look at the setup. PAC is a thermal cutting process that uses a constricted jet of high-temperature plasma gas to melt and separate metal. The plasma arc is formed between a negatively charged electrode inside the torch and a positively charged work-piece. Heat from the transferred arc rapidly melts the metal, and the high-velocity gas jet expels the molten material from the cut. A plasma arc cutting torch has four components: The electrode carries the negative charge from the power supply, the swirl ring spins the plasma gas to create a swirling flow pattern, the nozzle constricts the gas flow and increases the arc energy density, and the shield channels the flow of shielding gas and protects the nozzle from metal spatter.

| plasma Arc Cutting And Welding girl And Plasma Cutter

We wanted to follow up our welding series with some more helpful fabrication tips that any mini-trucker could use. Since this happens to be the first-ever Chicks Special in the history of any custom-truck magazine, what better way to learn a few things about plasma cutting then to have some ladies on hand to actually demonstrate as we learn? We figured you wouldn't mind.

To understand the basics of plasma arc cutting (PAC), let's take a closer look at the setup. PAC is a thermal cutting process that uses a constricted jet of high-temperature plasma gas to melt and separate metal. The plasma arc is formed between a negatively charged electrode inside the torch and a positively charged work-piece. Heat from the transferred arc rapidly melts the metal, and the high-velocity gas jet expels the molten material from the cut. A plasma arc cutting torch has four components: The electrode carries the negative charge from the power supply, the swirl ring spins the plasma gas to create a swirling flow pattern, the nozzle constricts the gas flow and increases the arc energy density, and the shield channels the flow of shielding gas and protects the nozzle from metal spatter.

| plasma Arc Cutting And Welding welding

That's pretty much the long and short of it, so without further ado, sit back, grab a beer, and check out these girls as they school us in the basics of plasma cutting. For more information, contact the company listed in the source box.

| plasma Arc Cutting And Welding welding

That's pretty much the long and short of it, so without further ado, sit back, grab a beer, and check out these girls as they school us in the basics of plasma cutting. For more information, contact the company listed in the source box.

| plasma Arc Cutting And Welding cnc Plasma

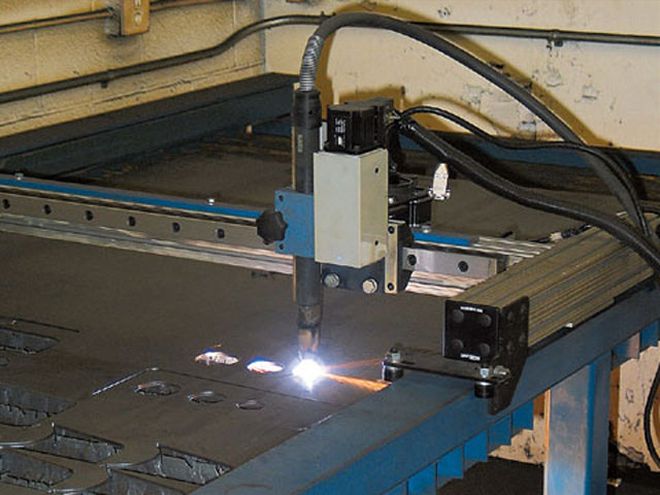

15.Once you get used to having a plasma cutter around, you'll see how much time it saves you. If you do a lot of cutting of brackets, mounts, or anything repetitive one option you might look into (if funds permit) is a CNC plasma. This fancy cutting wizard can really make your life easy and allow you to design some really cool parts.

| plasma Arc Cutting And Welding cnc Plasma

15.Once you get used to having a plasma cutter around, you'll see how much time it saves you. If you do a lot of cutting of brackets, mounts, or anything repetitive one option you might look into (if funds permit) is a CNC plasma. This fancy cutting wizard can really make your life easy and allow you to design some really cool parts.