| air Compressor Tests compressors

In life, more often than not experience will mean the difference between success and failure. Experience is a great tool to have when designing an efficient air suspension, too, but what do you do if you've never designed an air suspension before? Where do you turn for good information on the most important part of an air suspension, the air compressor? Magazine ads are great sales tools, but they usually don't provide all of practical information you'll need to make an informed decision, and brochures are only as good as the knowledge you possess to decipher their specs.

To clear the air (pun definitely intended!), we rounded up seven compressors and tested them to determine how fast each could fill a 2-gallon reserve air tank. We repeated this test several times to determine if the increase in operating temperature affected the compressor's output. We also pumped up the input voltage to determine the output of those compressors that could operate on more than 12 volts of power. And finally, we recorded the maximum amperage draw of each compressor to see if your mini-truck's electrical system is even up to the task of powering them. Our breakdown of each compressor will tell you how fast it will fill your air tank, how long it can operate, and how it will affect your truck's charging system.

Armed with this knowledge, you'll be able to pick the compressor that best suits your switch-hitting habits. Are you the type of person who only uses your air system to get you from Point A to Point B? Or are you hittin' switches at every stoplight and throwin' sparks on the freeway? Answer those two questions first and then you'll be able to select the right compressor for you. First, though, we must familiarize ourselves with all the of the important specifications that manufacturers use to rate their compressors. The compressor specs that matter the most are duty cycle, amperage draw, fill time, and airflow.

Duty cycle refers to the number of minutes an air compressor can operate at 100 psi, with an ambient temperature of 72 degrees Fahrenheit, divided by the number of minutes it must rest.

The equation looks like this:

X/(X+Y)= Z

X= compressor on time in minutes

Y= compressor off time in minutes

Z= duty cycle measured as a percentage

For example, a compressor that is rated as a 25 percent duty cycle compressor can operate continuously for 10 minutes at 100 psi and then must rest for 30 minutes. A 33 percent duty cycle compressor can operate for 15 minutes and must rest for 30 minutes. Everybody got that?

Current draw refers to the load (measured in ampheres) that the compressor places on the charging system of your truck. Amperage draw is an important spec because your truck's charging system needs to be up to the task of powering the compressor as well as all the other accessories. Technically speaking, the compressor, ignition system, audio system, and lighting system all run off of the battery, but it is the alternator that keeps the battery charged. If the output of the alternator cannot meet the demand for power that all of these accessories need, then the battery will die. Extended use will eventually burn out the alternator and destroy the battery and the compressors.

For example, if you install three compressors in your air system and each compressor draws 20 amps of current from the battery at maximum operating pressure, then a 60-amp load is being placed on the battery. Keep that number in mind because here are a few alternator output specs on four popular mini-trucks:

'98 Chevy S-10 2.2L four-cylinder engine, manual transmission

Alternator output: 100 amps

'00 Toyota Tacoma 2.4L four-cylinder engine, manual transmission

Alternator output: 80 amps

'95 Nissan Hardbody 2.4L four-cylinder engine, manual transmission

Alternator output: 60 amps

'86 Mazda B-2000 2.0L four-cylinder engine, manual transmission

Alternator output: 60 amps

These are peak output figures. This means the alternator is not making this amount of power if your truck is parked and idling. The alternator will only make peak power output when you are driving it down the road and the alternator is spinning at more than 2,500 rpm. If you happen to own an '86 Mazda B-2000 or a '95 Nissan Hardbody, then the amperage draw of the three compressors is exceeding the output of your truck's alternator. This is bad news! Even when you are driving your truck down the road at 60 mph, the alternator cannot keep up with the current demands of the compressors, let alone the ignition system, lighting system, or that big audio/video system you have in the cab of your mini. Over time, this scenario will lead to a dead battery, a fried alternator, and possible damage to the compressors. When you choose a compressor, make sure you've factored in the other current-draining equipment installed in your truck such as neon lighting, HID headlights, audio amplifiers, and so on. Careful planning will mean the difference between watching your headlights blink on and off whenever your air compressor turns on and having all of the electronic equipment in your truck operating at their full potential.

Airflow is measured in cubic feet per minute (cfm). Air compressor flow ratings are usually measured with 0 psi in the tank, which makes this specification very subjective. Measuring the airflow at 0 psi does you no good because the airflow at maximum operating pressure is what matters most. As pressure increases in the reserve tank, the airflow from the compressor decreases. So the true measure of airflow is the fill time. The quicker the compressor can fill your reserve tank, the more cfm of air it is pushing.

Fill time refers to the amount of time the compressor takes to fill up the reserve air tank in the system. The more efficient a compressor is, the faster it will refill the tank.

The Test We took seven different compressors to our ultra top-secret testing facility, Shop X, and proceeded to put them through their paces. Our test equipment consisted of a switchable 12/24-volt power supply that is backed up with a pair of deep-cycle marine batteries. Our test bench features a built-in flow meter, a digital multimeter for testing current draw, a stopwatch, and a 2-gallon air tank. Each compressor was connected to the power supply using 4-gauge power wire and to the tank using 1/2-inch air line. Our testing consisted of back-to-back runs during which each compressor filled the air tank to 150 psi. During the runs, we measured the operating temperature of the motor casing on each compressor using an infrared thermometer. We also measured the maximum current draw of each compressor using the digital multimeter and fill times using the stopwatch. Our target of 150 psi was established using a standard 145 psi pressure switch, which is widely used in most air suspension setups found on mini-trucks today. Here are the results and our evaluation of each compressor.

| air Compressor Tests viair 325c

Viar rates the 325c compressor with a 13.8-volt input supply. The 325c draws a maximum 19 amps at a maximum working pressure of 150 psi. The 325c is also rated as a 33 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.77 cfm at 0 psi and 0.76 cfm at 150 psi. The 325c weighs 6.95 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

CompressorViar 325C Current Draw Fill Time Temperature Test 1 16.7 2:{{{57}}} 87 Test 2 16.4 3:08 120 Test 3 16.3 3:13 138

Evaluation The 325c worked very well with minimal current draw. This compressor would work very well in a multiple compressor install without pulling too many amps from your battery.

| air Compressor Tests viair 400c

Viar rates the 400c compressor with a 13.8-volt input supply. The 400c draws a maximum 30 amps at a maximum working pressure of 150 psi. The 400c is also rated as a 33 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 2.54 cfm at 0 psi and 0.71 cfm at 150 psi. The 400c weighs 8 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

Compressor Viar 400C Current Draw Fill Time Temperature 1. 26.4 1:30 78 2. 25.9 1:36 86 3. 24.4 1:44 95

Evaluation The 400c motored its way to a super-fast fill time. We'd run this compressor by itself any day of the week.

| air Compressor Tests viair 450c

Viar rates the 450c compressor with a 13.8-volt input supply. The 450c draws a maximum 23 amps at a working pressure of 150 psi. The 400c is rated as a 100 percent duty cycle compressor when operating at 100 psi. Maximum air flow is 1.66 cfm at 0 psi and 0.71 cfm at 150 psi. The 450c weighs 9.75 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

Compressor Viar 450C Current Draw Fill Time Temperature Test 1 18.9 2:05 77 Test 2 18.0 2:20 82 Test 3 17.8 2:23 {{{90}}}

Evaluation The 450c has a fairly low current draw and respectable fill time. Its most important benefit, though, is that it is a 100 percent duty cycle compressor. Run it all day long and keep hittin' switches!

| air Compressor Tests thomas Compressor

Chassis Tech rates the DC-2000 with a 12-volt input supply. The DC-2000 draws a maximum 23 amps at a working pressure of 150 psi. The DC-2000 is a 50 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.38 cfm at 0 psi and 1 cfm at 150 psi. The DC-2000 compressor is rebuildable and Chassis Tech sells a full line of parts to renew its performance. Chassis Tech also offers extended an extended warranty on this compressor.

Compressor

Chassis Tech DC2000 Current Draw Fill Time Temperature Test 1 17.0 4:20 95 Test 2 16.7 4:21 129 Test 3 15.8 4:33 155

Evaluation The DC-2000 is a great entry-level compressor. We recommend this compressor for anyone who is looking for longevity and not speed. This is a great compressor for anyone who uses their air suspension strictly to get from Point A to Point B and is also looking for a compressor that won't pull a ton of current from the battery.

| air Compressor Tests chassis Tech Dc5000

Chassis Tech rates the DC-5000 with a 12-volt input supply. The DC-5000 draws a maximum 23 amps at a working pressure of 150 psi. The DC-5000 is a 50 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.38 cfm at 0 psi and 1 cfm at 150 psi. The DC-5000 compressor is rebuildable and Chassis Tech sells a full line of parts to renew its performance. Chassis Tech also offers extended an extended warranty on this compressor.

Compressor

Chassis Tech DC5000 Current Draw Fill Time Temperature Test 1 39.5 1:34 87 Test 2 39.5 1:38 95 Test 3 39.0 1:39 104

Evaluation This monster runs extremely cool, fills quick, and draws less than 40 amps at peak operating pressure. This is a great compressor for a single unit install and will keep the tanks full.

| air Compressor Tests thomas 315cd

For the sake of comparison, we tested the old standby Thomas 315cd compressor. Chassis Tech rates this compressor with a 12-volt input supply. The 315cd draws a maxim 21 amps at a working pressure of 120 psi. The 315cd is a 20 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 0.71 cfm at 0 psi and 0.4 cfm at 120 psi.

Compressor

Thomas 315CD Current Draw Fill Time Temperature Test 1 18.2 3:29 90 Test 2 17.0 3:48 130 Test 3 Compressor shut off before reaching 150psi because the thermal protection circuit engaged.

Evaluation In all fairness, the 315cd was never designed to operate at 150 psi. The lack of heat sinks around the pump head prevented it from keeping cool even when operating at 120 psi. Thomas 315cd makes a good light-duty compressor for occasional use, low pressure air suspensions. Trying to push it for longer than seven minutes at 120 psi or running it at 150 psi will only shorten its life span.

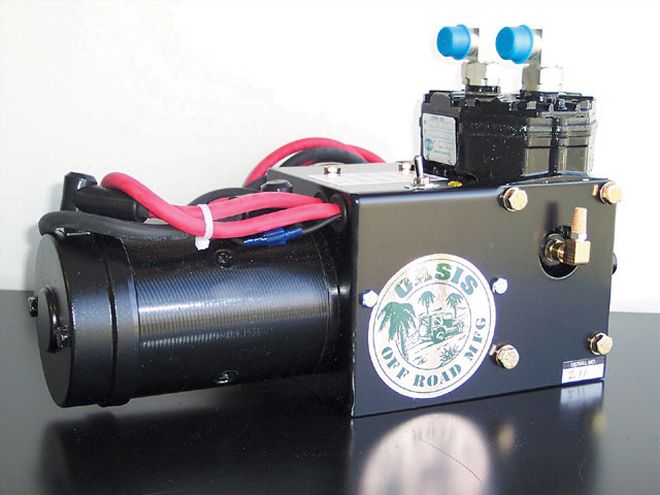

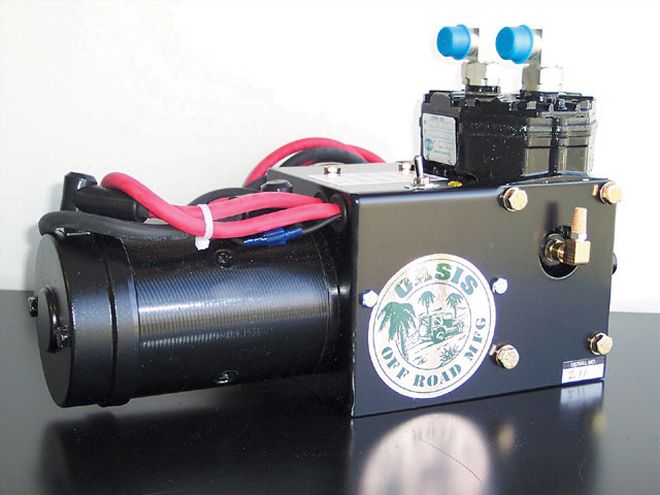

| air Compressor Tests oasis Trailhead

Oasis Offroad MFGs rates the Trailhead compressor with both 12- and 24-volt input supplies. The Trailhead draws a maximum 180 amps at a working pressure of 150 psi. The Trailhead is a 100 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 14 cfm at 0 psi in 12-volt configuration and 25 cfm at 0 psi in 24-volt mode.

Compressor

Oasis Trailhead Current Draw Fill Time Temperature Test 1 189 21.37 87 Test 2 190 21.38 94 Test 3 192 24.00 115 Test 4 (at 24V) 180 11.27 150

Evaluation The Trailhead is the sickest compressor we've ever tested. Its brute power will fill your air tanks up in no time at all. But all of this power does come with a cost. The Trailhead draws a ton of current to make all of its power. Its 190 amp current demand was nearly three times higher than of any other compressors tested, but it also got the job done in a third of the time.

| air Compressor Tests compressors

In life, more often than not experience will mean the difference between success and failure. Experience is a great tool to have when designing an efficient air suspension, too, but what do you do if you've never designed an air suspension before? Where do you turn for good information on the most important part of an air suspension, the air compressor? Magazine ads are great sales tools, but they usually don't provide all of practical information you'll need to make an informed decision, and brochures are only as good as the knowledge you possess to decipher their specs.

To clear the air (pun definitely intended!), we rounded up seven compressors and tested them to determine how fast each could fill a 2-gallon reserve air tank. We repeated this test several times to determine if the increase in operating temperature affected the compressor's output. We also pumped up the input voltage to determine the output of those compressors that could operate on more than 12 volts of power. And finally, we recorded the maximum amperage draw of each compressor to see if your mini-truck's electrical system is even up to the task of powering them. Our breakdown of each compressor will tell you how fast it will fill your air tank, how long it can operate, and how it will affect your truck's charging system.

Armed with this knowledge, you'll be able to pick the compressor that best suits your switch-hitting habits. Are you the type of person who only uses your air system to get you from Point A to Point B? Or are you hittin' switches at every stoplight and throwin' sparks on the freeway? Answer those two questions first and then you'll be able to select the right compressor for you. First, though, we must familiarize ourselves with all the of the important specifications that manufacturers use to rate their compressors. The compressor specs that matter the most are duty cycle, amperage draw, fill time, and airflow.

Duty cycle refers to the number of minutes an air compressor can operate at 100 psi, with an ambient temperature of 72 degrees Fahrenheit, divided by the number of minutes it must rest.

| air Compressor Tests compressors

In life, more often than not experience will mean the difference between success and failure. Experience is a great tool to have when designing an efficient air suspension, too, but what do you do if you've never designed an air suspension before? Where do you turn for good information on the most important part of an air suspension, the air compressor? Magazine ads are great sales tools, but they usually don't provide all of practical information you'll need to make an informed decision, and brochures are only as good as the knowledge you possess to decipher their specs.

To clear the air (pun definitely intended!), we rounded up seven compressors and tested them to determine how fast each could fill a 2-gallon reserve air tank. We repeated this test several times to determine if the increase in operating temperature affected the compressor's output. We also pumped up the input voltage to determine the output of those compressors that could operate on more than 12 volts of power. And finally, we recorded the maximum amperage draw of each compressor to see if your mini-truck's electrical system is even up to the task of powering them. Our breakdown of each compressor will tell you how fast it will fill your air tank, how long it can operate, and how it will affect your truck's charging system.

Armed with this knowledge, you'll be able to pick the compressor that best suits your switch-hitting habits. Are you the type of person who only uses your air system to get you from Point A to Point B? Or are you hittin' switches at every stoplight and throwin' sparks on the freeway? Answer those two questions first and then you'll be able to select the right compressor for you. First, though, we must familiarize ourselves with all the of the important specifications that manufacturers use to rate their compressors. The compressor specs that matter the most are duty cycle, amperage draw, fill time, and airflow.

Duty cycle refers to the number of minutes an air compressor can operate at 100 psi, with an ambient temperature of 72 degrees Fahrenheit, divided by the number of minutes it must rest. | air Compressor Tests viair 325c

Viar rates the 325c compressor with a 13.8-volt input supply. The 325c draws a maximum 19 amps at a maximum working pressure of 150 psi. The 325c is also rated as a 33 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.77 cfm at 0 psi and 0.76 cfm at 150 psi. The 325c weighs 6.95 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

CompressorViar 325C Current Draw Fill Time Temperature Test 1 16.7 2:{{{57}}} 87 Test 2 16.4 3:08 120 Test 3 16.3 3:13 138 Evaluation

| air Compressor Tests viair 325c

Viar rates the 325c compressor with a 13.8-volt input supply. The 325c draws a maximum 19 amps at a maximum working pressure of 150 psi. The 325c is also rated as a 33 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.77 cfm at 0 psi and 0.76 cfm at 150 psi. The 325c weighs 6.95 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

CompressorViar 325C Current Draw Fill Time Temperature Test 1 16.7 2:{{{57}}} 87 Test 2 16.4 3:08 120 Test 3 16.3 3:13 138 Evaluation  | air Compressor Tests viair 400c

Viar rates the 400c compressor with a 13.8-volt input supply. The 400c draws a maximum 30 amps at a maximum working pressure of 150 psi. The 400c is also rated as a 33 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 2.54 cfm at 0 psi and 0.71 cfm at 150 psi. The 400c weighs 8 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

Compressor Viar 400C Current Draw Fill Time Temperature 1. 26.4 1:30 78 2. 25.9 1:36 86 3. 24.4 1:44 95 Evaluation

| air Compressor Tests viair 400c

Viar rates the 400c compressor with a 13.8-volt input supply. The 400c draws a maximum 30 amps at a maximum working pressure of 150 psi. The 400c is also rated as a 33 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 2.54 cfm at 0 psi and 0.71 cfm at 150 psi. The 400c weighs 8 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

Compressor Viar 400C Current Draw Fill Time Temperature 1. 26.4 1:30 78 2. 25.9 1:36 86 3. 24.4 1:44 95 Evaluation  | air Compressor Tests viair 450c

Viar rates the 450c compressor with a 13.8-volt input supply. The 450c draws a maximum 23 amps at a working pressure of 150 psi. The 400c is rated as a 100 percent duty cycle compressor when operating at 100 psi. Maximum air flow is 1.66 cfm at 0 psi and 0.71 cfm at 150 psi. The 450c weighs 9.75 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

Compressor Viar 450C Current Draw Fill Time Temperature Test 1 18.9 2:05 77 Test 2 18.0 2:20 82 Test 3 17.8 2:23 {{{90}}} Evaluation

| air Compressor Tests viair 450c

Viar rates the 450c compressor with a 13.8-volt input supply. The 450c draws a maximum 23 amps at a working pressure of 150 psi. The 400c is rated as a 100 percent duty cycle compressor when operating at 100 psi. Maximum air flow is 1.66 cfm at 0 psi and 0.71 cfm at 150 psi. The 450c weighs 9.75 pounds. A one-year limited warranty covers defects in workmanship and materials under normal operating conditions.

Compressor Viar 450C Current Draw Fill Time Temperature Test 1 18.9 2:05 77 Test 2 18.0 2:20 82 Test 3 17.8 2:23 {{{90}}} Evaluation  | air Compressor Tests thomas Compressor

Chassis Tech rates the DC-2000 with a 12-volt input supply. The DC-2000 draws a maximum 23 amps at a working pressure of 150 psi. The DC-2000 is a 50 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.38 cfm at 0 psi and 1 cfm at 150 psi. The DC-2000 compressor is rebuildable and Chassis Tech sells a full line of parts to renew its performance. Chassis Tech also offers extended an extended warranty on this compressor.

Compressor

| air Compressor Tests thomas Compressor

Chassis Tech rates the DC-2000 with a 12-volt input supply. The DC-2000 draws a maximum 23 amps at a working pressure of 150 psi. The DC-2000 is a 50 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.38 cfm at 0 psi and 1 cfm at 150 psi. The DC-2000 compressor is rebuildable and Chassis Tech sells a full line of parts to renew its performance. Chassis Tech also offers extended an extended warranty on this compressor.

Compressor | air Compressor Tests chassis Tech Dc5000

Chassis Tech rates the DC-5000 with a 12-volt input supply. The DC-5000 draws a maximum 23 amps at a working pressure of 150 psi. The DC-5000 is a 50 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.38 cfm at 0 psi and 1 cfm at 150 psi. The DC-5000 compressor is rebuildable and Chassis Tech sells a full line of parts to renew its performance. Chassis Tech also offers extended an extended warranty on this compressor.

Compressor

| air Compressor Tests chassis Tech Dc5000

Chassis Tech rates the DC-5000 with a 12-volt input supply. The DC-5000 draws a maximum 23 amps at a working pressure of 150 psi. The DC-5000 is a 50 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 1.38 cfm at 0 psi and 1 cfm at 150 psi. The DC-5000 compressor is rebuildable and Chassis Tech sells a full line of parts to renew its performance. Chassis Tech also offers extended an extended warranty on this compressor.

Compressor | air Compressor Tests thomas 315cd

For the sake of comparison, we tested the old standby Thomas 315cd compressor. Chassis Tech rates this compressor with a 12-volt input supply. The 315cd draws a maxim 21 amps at a working pressure of 120 psi. The 315cd is a 20 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 0.71 cfm at 0 psi and 0.4 cfm at 120 psi.

Compressor

| air Compressor Tests thomas 315cd

For the sake of comparison, we tested the old standby Thomas 315cd compressor. Chassis Tech rates this compressor with a 12-volt input supply. The 315cd draws a maxim 21 amps at a working pressure of 120 psi. The 315cd is a 20 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 0.71 cfm at 0 psi and 0.4 cfm at 120 psi.

Compressor  | air Compressor Tests oasis Trailhead

Oasis Offroad MFGs rates the Trailhead compressor with both 12- and 24-volt input supplies. The Trailhead draws a maximum 180 amps at a working pressure of 150 psi. The Trailhead is a 100 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 14 cfm at 0 psi in 12-volt configuration and 25 cfm at 0 psi in 24-volt mode.

Compressor

| air Compressor Tests oasis Trailhead

Oasis Offroad MFGs rates the Trailhead compressor with both 12- and 24-volt input supplies. The Trailhead draws a maximum 180 amps at a working pressure of 150 psi. The Trailhead is a 100 percent duty cycle compressor when operating at 100 psi. Maximum airflow is 14 cfm at 0 psi in 12-volt configuration and 25 cfm at 0 psi in 24-volt mode.

Compressor