The two-part question was a simple one. How much boost will a stock 5.3L short-block withstand before the proverbial Big Bang and what is the resulting power output? The web is chock-full of speculation, ranging from absurd to the insane. What will go first? Will the sleeves split in the block or will the power level simply push the crank out the bottom? The smart money is on the notoriously weak cast pistons and powdered metal connecting rods, since neither was designed by GM to withstand the rigors of boost. Rather than rely on viral videos or Internet banter, we decided to find out for ourselves. Having run a similar test for Hot Rod with a 4.8L, we decided to step up to the larger (and more popular) 5.3L LM7 truck motor. Just how tough is the 5.3L? The results of this test will amaze you and make you proud to own a 5.3L Chevy.

| After 24 psi and 1,300 hp, what does it take to break a 5.3L?

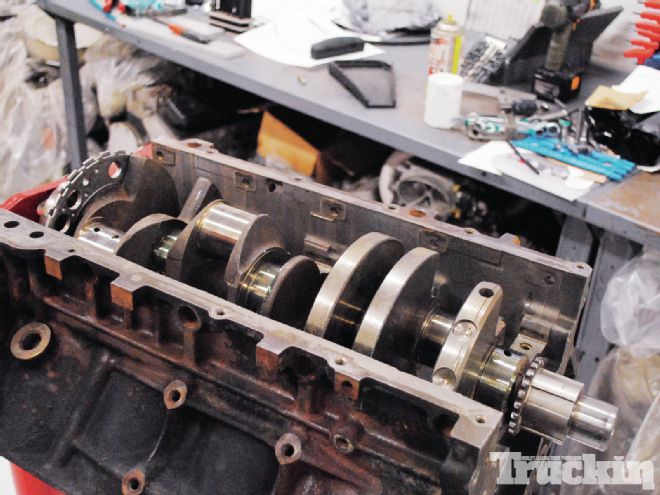

The procedure for our Big Bang test was equally simple. We purchased a used (supposedly running) 5.3L truck motor (circa 2003) from a dismantler in Ohio and had it shipped to Westech Performance. Rather than just pull it from the shipping crate and run it, we decided to do a little prep. The engine was first disassembled to ensure it was a worthy candidate. The last thing we wanted was an unusable core with rusty innards or a spun cam bearing. The motor was listed as having logged 160,000 miles, and looked liked frequent oil changes were not part of the maintenance schedule. In addition to checking out the internals, we also wanted to perform a little boost-prerequisite modification to the otherwise stock short-block. The real reason most stock motors fail under boost is insufficient ring gap. The rings heat up and expand until the ring gap is eliminated. Once this happens, the ring can momentarily stick in the bore and snap the ring land off the piston. Damage that is usually attributed to weak piston design is actually insufficient ring gap. Knowing we were going for broke, we gapped the rings aggressively—meaning over .035 for both top and second rings.

While performing the regap procedure on the original 160,000-mile rings (new rings would be cheating), we also addressed a couple issues with the stock pistons. The excessive mileage and (PCV-related) oil consumption left hardened sludge in the ring lands (behind the rings). This was cleaned using a pick, screwdriver and brake cleaner. Scuffed piston skirts were addressed with a little oil and Scotch brite pads. The one machining operation performed was to ball hone the block. Given the high-mileage rings and excessive ring gap, this was probably unnecessary, but we felt better giving the tired truck motor a little love before sending it to its doom. Once everything was cleaned, we reassembled the short-block using the original bearings. We did take the liberty of installing a new oil pump from Federal Mogul. Though we were tempted, we refrained from replacing the seals in the front, rear, and valley covers. Even the original oil pan gasket was deemed adequate for this destruction test. With the stock short-block now boost ready, it was time for some modifications.

You might be wondering why we would choose to modify any components in this strength test, but the answer is a simple one. The power output of any turbocharged motor is a function of the power output of the normally aspirated motor multiplied by the boost pressure (pressure ratio). Your normally aspirated motor is actually running at an atmospheric pressure of 14.7 psi. If you double this atmospheric pressure (by supplying boost from a turbo or blower), you can theoretically double the power output of your motor. This formula works regardless of the original power output. If we were to run the 5.3L in stock trim, the resulting power output would be around 360 hp (on this dyno, the way we test). If we apply 14.7 psi from our turbos to the stock 360hp motor, we might get 720 hp. If, on the other hand, we increase the power output of the motor with ported heads, a cam and intake to 500 hp, then adding 14.7 psi will result in an even 1,000 hp. Having a more powerful normally aspirated motor allows you to produce more power with the turbos at a lower boost pressure. More than just the boost limit of the motor, we wanted a big power number to go along with it.

| 7. To ensure proper sealing, we installed a set of Fel Pro MLS head gaskets and ARP head studs.

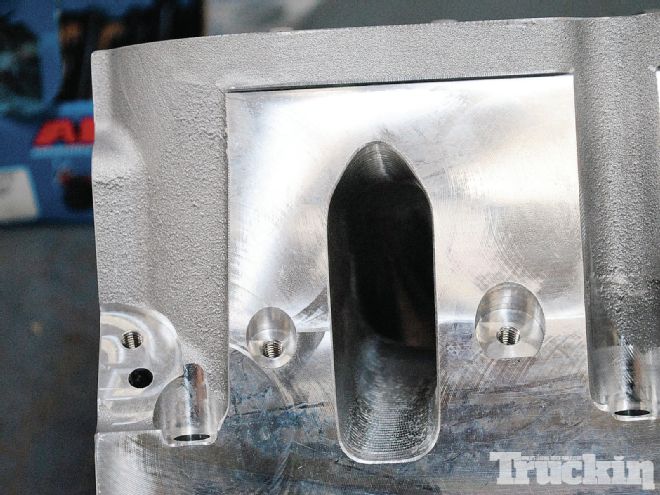

Wanting big boost and big power to test the limits of the internal components of the stock short-block, we swapped out the stock cam, heads and intake manifold. The mild 5.3L truck cam was replaced by a healthy 281LR HR13 cam from Comp Cams. The LSR cathedral-port grind offered a .617/.624 lift split, a 231/239-degree duration split and a boost-friendly 113-degree LSA. The powerful cam was teamed with a set of GenX 215 heads from Trick Flow Specialties. The GenX 215 heads featured full CNC porting, 215cc intake ports and a 2.04/1.575 stainless steel valve package. The GenX 215 heads were designed for the slightly larger 3.902 bore but worked without interference on the smaller 3.78-inch bore. The GenX 215 heads offered not only exceptional airflow (over 320 cfm), but also a thicker deck surface than the stock 5.3L heads. The heads were combined with a truck-oriented Fast LSXRT intake and matching 102mm throttle body. The dedicated fuel rails were stuffed with injectors that flowed a whopping 160 pounds per hour—we were not lacking for fuel! Wanting to maximize sealing under high boost, we installed a set of Fel Pro MLS head gaskets (.053 thick and 3.950 bore) and ARP head studs. The 64cc chambers on the GenX heads lowered the static compression of our 5.3L by nearly half a point.

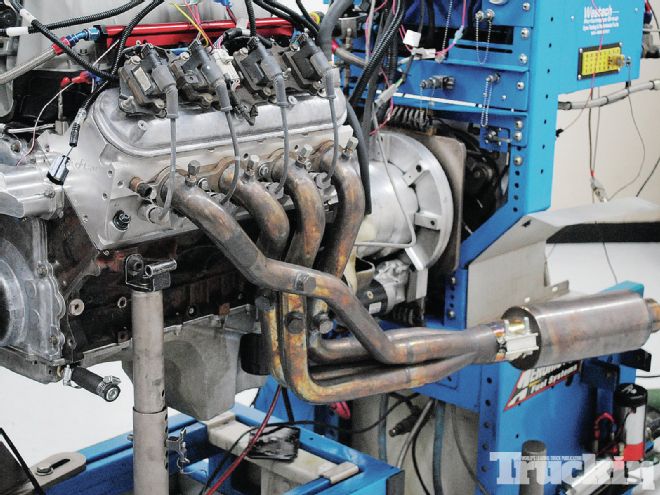

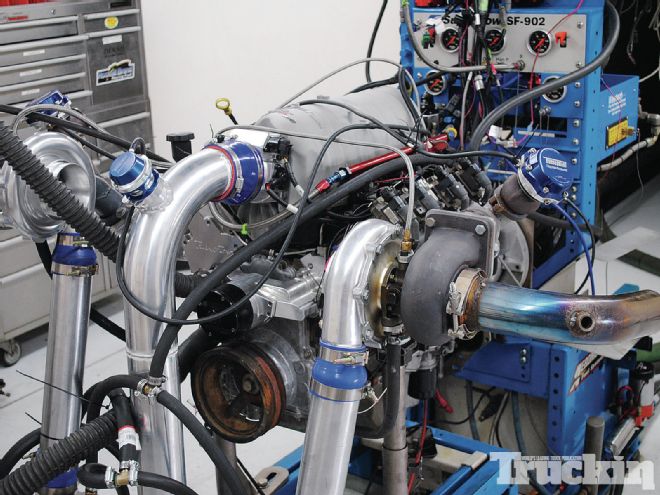

After a break-in procedure, Westech’s Ernie Mena dialed in the tune on the 5.3L using the Fast XFI/XIM management system. The normally aspirated 5.3L eventually produced 503 hp at 6,600 rpm and 441 lb-ft of torque at 5,700 rpm. The new heads, cam, and intake shifted the power curve higher in the rev range, as a stock 5.3L will produce peak power at just 5,400 rpm. We were impressed by the power of the little 5.3L, but were anxious to get this thing under boost. We installed a homemade turbo system consisting of a set of JBA shorty truck headers and adapter tubes to mount the T4-based, 76mm turbos from CX Racing. CX Racing also supplied the air-to-water intercooler, aluminum tubing and silicone couplers. They even had all the small parts like oil feed and drain kits, making them and excellent source for the do-it-yourselfer. To properly control the boost on this monster, we relied on a pair of 45mm Hyper Gate wastegates, a manual wastegate controller, and a Race Port blow-off valve all from Turbo Smart.

| 8. It is possible to run stock or (better yet) ported stock 5.3L heads but make sure to upgrade the stock valve springs. Brian Tooley Racing offers three different performance spring upgrades for LS heads.

Wanting strength and not octane to be the destructive force, we replaced the 91-octane fuel with 118-octane race fuel from Rocket Brand. Truth be told, improper tuning has probably killed more engines than insufficient ring gap, but the two are likely responsible for the majority of boost-related Big Bangs. We kept the total timing on the conservative side (around 18 degrees) and snuck up on boost and power levels. The motor was loaded at 3,000 rpm and allowed to run to 6,300 rpm, though peak power was actually some 300 to 400 rpm higher. Running just 5.5 psi, the twin-turbo 5.3L produced 696 hp and 606 lb-ft of torque. Stepping up to 13.0 psi resulted in 930 hp and 806 lb-ft of torque, while 15.5 psi took us over 1,000 hp to 1,014 hp and 872 lb-ft of torque. Adjusting the manual wastegate controller to a peak of 18.3 psi brought 1,094 hp and 950 lb-ft of torque then 1,174 hp and 1008 lb-ft at 21.0 psi. A few more clicks of the controller upped the power ante to 1,245 hp and 1,056 lb-ft of torque and the highest boosted run of the day recorded an amazing 1,308 hp and 1,109 lb-ft of torque at 24.2 psi before the Big Bang finally came through.

| 15. Run in normally aspirated trim, the modified 5.3L produced 503 hp at 6,600 rpm and 441 lb-ft of torque at 5,700 rpm. Torque production exceeded 400 lb-ft from 4,400 rpm to 6,600 rpm.

Actually, the Big Bang was more of a little whimper, as the power simply fell off and a check of the dreaded cylinder number seven revealed absolutely no compression. Figuring we killed a piston, connecting rod or both, we called it a day. Before pulling the motor, we decided to check out the internals for a few post-mortem photos. After pulling the turbos, intercooler and valve covers, we discovered the missing compression was not caused by damage to a piston or rod, but rather a broken lifter and pushrod. During testing the higher boost levels, we experienced a misfire that we figured was ignition related. After several attempts to cure it, the power dropped and we thought we had killed the 5.3L. We now suspect the culprit to be valve float, and the hammering of the lifter points in this direction. Before removing the 5.3L, we decided to find out if it was indeed still alive. We replaced the broken lifter and pushrod and ran the motor once again in normally aspirated trim. Though the output was down by roughly 15 hp (excessive blow caused by a combination of 160,000 miles, over .035 ring gap and 70 runs over 1,000 hp), the 1,300hp Big Bang 5.3L was still alive, kicking and ready for more boost (and maybe a new set of rings).

| 16. Next, we installed a pair of 76mm turbos from CX Racing. Capable of supporting over 750 hp each, they were more than adequate for our twin-turbo 5.3L.

Big Bang 5.3L NA vs. Turbo (5.5 psi) vs. Turbo 15.5 psi vs. Turbo 24.2 psi

NA

5.5 psi

15.5 psi

24.2 psi

RPM

HP

TQ

HP

TQ

HP

TQ

HP

TQ

3000

209

365

250

438

251

439

224

394

3200

220

362

267

439

271

446

241

395

3400

234

361

290

448

296

457

267

412

3600

248

362

323

471

338

494

317

463

3800

267

369

362

501

393

542

371

512

4000

293

384

404

531

478

628

446

585

4200

313

391

430

537

568

711

549

686

4400

341

407

453

542

629

751

647

773

4600

377

430

495

565

704

804

841

961

4800

401

438

535

585

785

858

984

1077

5000

414

435

559

588

821

863

1056

1109

5200

428

433

576

583

850

858

1089

1100

5400

451

439

601

584

572

858

1122

1091

5600

472

443

636

596

921

864

1168

1096

5800

483

437

669

606

962

872

1212

1098

6000

492

430

689

603

994

870

1254

1098

6200

497

421

695

589

1011

856

1295

1095

6300

499

416

NA

NA

1013

845

1308

1091

6600

503

400

NA

NA

NA

NA

NA

NA

| 17. The homemade turbo kit consisted of a set of JBA truck headers turned upside down feeding adapter tubes designed to mount the turbos. Note the orientation of the wastegate flanges.

| 24. After a less-than-spectacular Big Bang on the last run, we pulled the motor apart to find not the expected damaged cast piston or powdered-metal rod, but a damaged lifter and pushrod. Replacing the damaged components revived the 5.3L and with a fresh set of rings, it could soon be up for another round of boost!

| 17. The homemade turbo kit consisted of a set of JBA truck headers turned upside down feeding adapter tubes designed to mount the turbos. Note the orientation of the wastegate flanges.

| 17. The homemade turbo kit consisted of a set of JBA truck headers turned upside down feeding adapter tubes designed to mount the turbos. Note the orientation of the wastegate flanges.

| 24. After a less-than-spectacular Big Bang on the last run, we pulled the motor apart to find not the expected damaged cast piston or powdered-metal rod, but a damaged lifter and pushrod. Replacing the damaged components revived the 5.3L and with a fresh set of rings, it could soon be up for another round of boost!

| 24. After a less-than-spectacular Big Bang on the last run, we pulled the motor apart to find not the expected damaged cast piston or powdered-metal rod, but a damaged lifter and pushrod. Replacing the damaged components revived the 5.3L and with a fresh set of rings, it could soon be up for another round of boost!