As the cost of new diesel pickups increases, the need to protect our investment also rises. One of the most important things that effects engine longevity is clean fluids. We all know the importance of clean oil, air, and fuelbut we usually don’t think about our coolant until the system fails at the worst possible moment. That is why having an easy to change, spin-on coolant filter (or two in this case) is such a good idea. According to DieselSite, contamination created by the process of making engine blocks loosens up after time. This debris then finds its way into the cooling system and can cause internal abrasions to the hoses, water pump seals, and radiator. Flaking supplemental cooling additives (SCA) are also known to form, and these projectiles can cause problems if not removed. Another thing to consider is the reduced performance or destruction a partially blocked or clogged air-to-water intercooler can wreak.

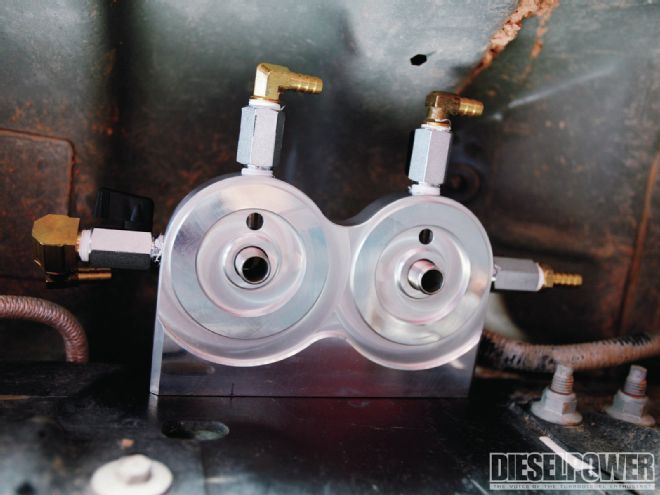

| DieselSite’s coolant filters can be mounted in any position. On trucks without the transfer case skidplate, they are easily mounted upside down using the two holes already drilled (notice the two gray bolt heads with larger washers holding the skidplate to the left of the Baldwin coolant filters) in the frame from the factory. Our truck had the skidplate package, so Loren Taylor from Diesel Tech mounted the filters to the right of the skidplate as shown.

Ford’s Unique Cooling System

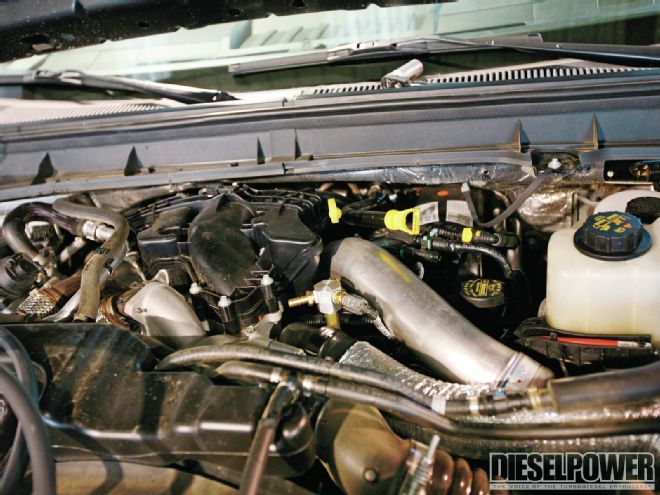

There are two separate cooling systems on Ford’s new engine: a high-temperature system that runs at 194 degrees to cool the engine, and a low-temperature system that cools an air-to-water intercooler, transmission fluid, fuel cooler, and EGR system with a 122-degree coolant. A beltdriven pump mounted low on the driver side circulates the high-temperature coolant, while a separate beltdriven pump mounted higher on the passenger side circulates the low-temperature coolant. Given the complexity and multiple critical components associated with this cooling system, it only makes sense to give it filter protectionespecially considering these components are probably not that easy or cheap to replace.

DieselSite’s Coolant Filtration Kit

DieselSite is now offering a coolant bypass filtration kit for the Ford ’11 6.7L Power Stroke. The filters are mounted on the passenger-side framerail and tap into the two cooling circuits by removing the coolant temperature sensors (one in each cylinder head) and adding a small pipe with a machined-aluminum adapter to the top of the pipe. These adapters allow the factory coolant sensor to be replaced and also provide the coolant out for the filter system. The coolant then runs via rubber hose to the filters on the framerail and gets returned to the engine by teeing into the two coolant recovery bottles’ plumbing. Since this is a bypass system, only a fraction of the fluid is directed into the filter, but the entire system gets cleaned.

Follow along as Loren Taylor of Diesel Tech fits this Super Duty with an investment-protecting, easy-to-install product.

Recommendations On Filter Changes

Use one filter every three months for the first nine months after installation. The lack of flow into the expansion tank is an indication that your filter is plugged. Change the filter if it should plug before the 3-month interval. After the fourth filter is installed, your filter should be changed once per year.