Bob Bergman owns www.DieselOrings.com where you can find all kinds of helpful parts to fix your truck. He is an active participant at www.ford-trucks.com and www.powerstroke.org, and he has a website (www.guzzle7pt3.com) where he posts articles under the username Guzzle on how to fix trucks. This is one of his articles. His opinions and statements are his own.

| You can rebuild your own fuel bowl—save money and a trip to the dealer. Plus, you'll feel better about yourself!

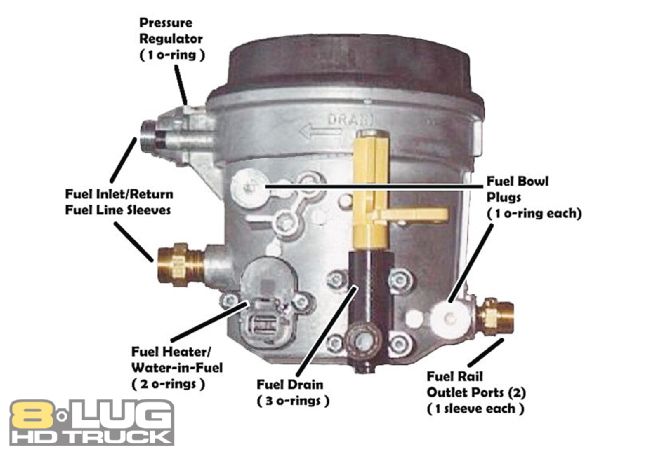

Fuel filter canisters (commonly known as fuel bowls) are of the same design on the '99 through '03 Ford 7.3L Power Stroke diesels. If you have found fuel dripping under your truck and coating the front axle or have fuel puddles in the engine valley, there is no need to go to the Ford dealer and spend $250 to get your leak fixed.

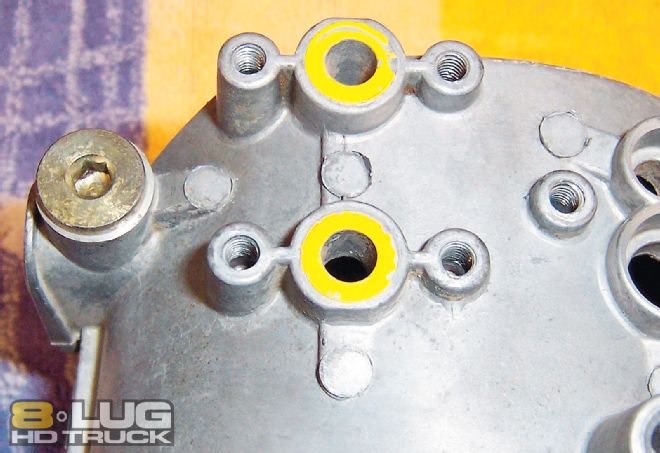

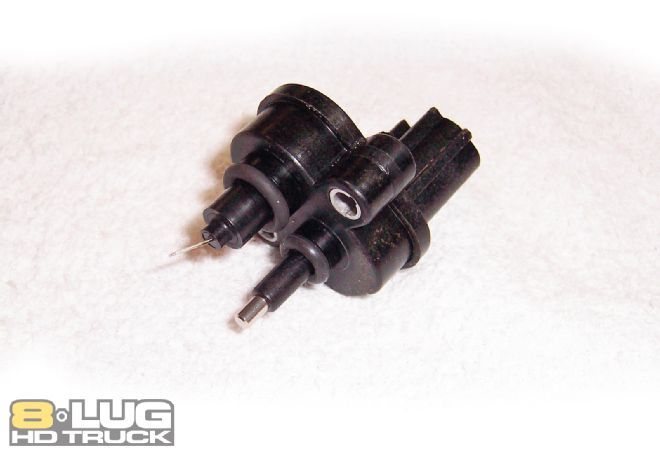

Although the fuel manufacturers have not claimed responsibility, the number of reported fuel leaks on the 7.3Ls can't reasonably be accounted to coincidence since the introduction of ultra-low-sulfur diesel fuel (ULSD). What I have found is that some of the chemical additives in ULSD are separating the PTFE coatings (that Ford uses on its fuel and oil seals) from the O-rings and seals themselves.

When the coatings separate, the PTFE coating does not separate evenly, leaving gaps that fuel can travel past in the sealing surface, causing the leak to appear (usually) on top of the engine.

Many of the O-rings are made of Buna-N, which has a greater percentage of swell than other elastomers offered in the industry, namely Viton. Fuel permeation and swell causes the elastomer to become soft and unable to seal the fuel pressures found in the 7.3L injection system.

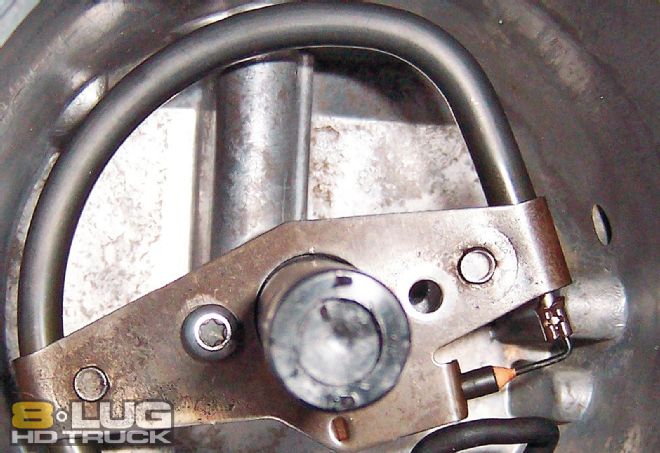

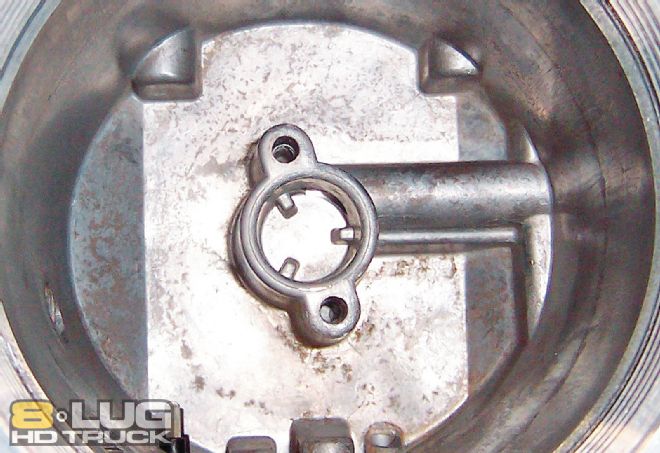

The fuel bowl can be rebuilt while it is still in the engine bay, but I have found that a more thorough job of cleaning can be performed if it is removed and serviced on the workbench.

Parts And Supplies To Rebuild The Fuel Filter Canister

Complete fuel bowl O-ring and fuel line sleeve kit

(8 O-rings - 4 Parker Vibra-Lok sleeves available at www.DieselOrings.com for $16.00 a set)

* T-20 Torx bit driver

* T-25 Torx bit driver

* Parts cleaner solvent and tray (or plenty of brake cleaner)

* 2 feet of 3/8-inch hose to attach over the drain

tube under the engine

* Drain pan/container to catch the fuel when

emptying the fuel bowl

* Lacquer thinner to remove PTFE residue from

canister and fittings

* Shop rags

REASSEMBLY

Installing The Vibra-Lok Fuel Line Sleeves,

Fuel Inlet, Return, And Cylinder Head Fuel Rail Lines

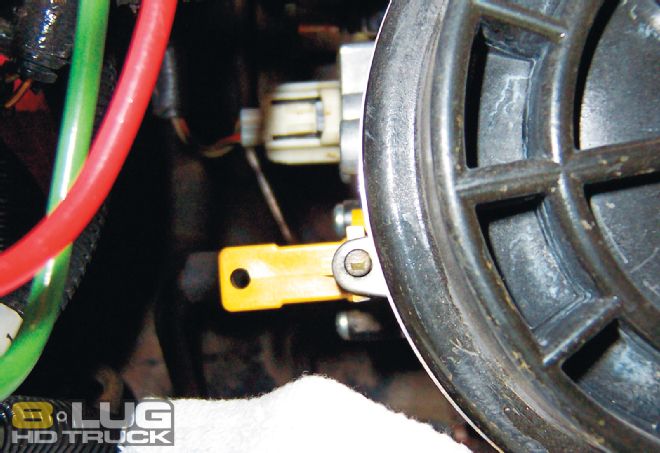

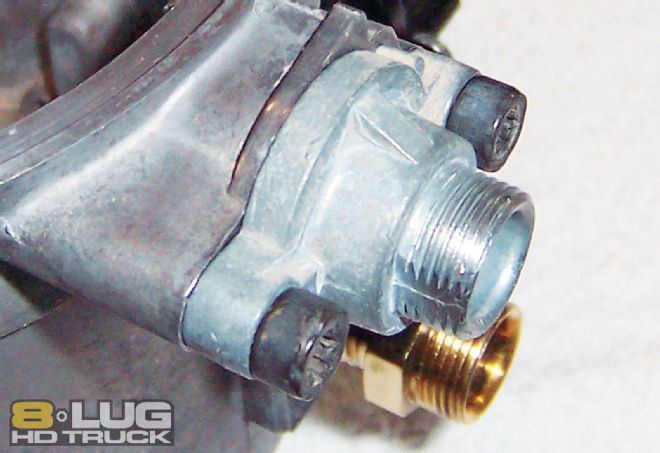

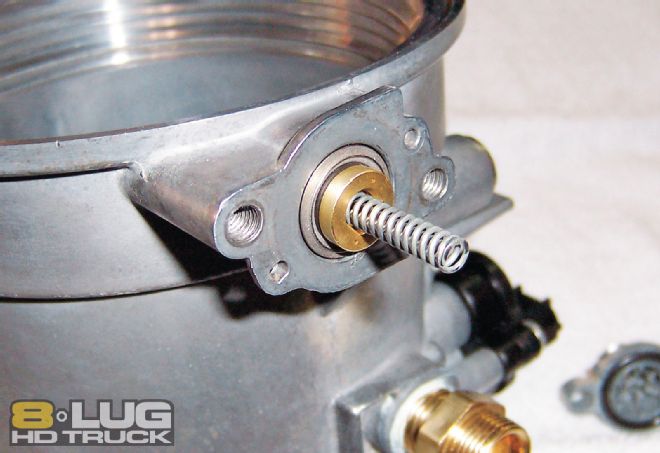

1. Remove the line from the fuel bowl fittings. You will find that the sleeves have become hard, dry, and cracked.

2. To remove the old sleeves, use a small screwdriver and/or pick tool to dig the old sleeve from the compression nut.

3. Use a commercially available brake cleaner to flush out the remnants of the old sleeve from the nut.

4. Lubricate the new sleeve with light oil or diesel fuel and push it over the flared end of the fuel line.

5. Push the fuel line into the fitting until it stops. Tighten the nut to the fittings while making sure the tubing stays fully inserted in the fitting.

6. The nut on a Vibra-Lok fitting must be tightened until it contacts the body of the fitting.