Connecting rod failures are known to cause some of the most catastrophic engine damage imaginable. And in the modern diesel engine's case, its connecting rods are subjected to very high levels of stress. Among many things, a thrown rod can lead to scarred cylinder walls, a damaged crankshaft, busted camshaft, and even a hole in the side of the block-oftentimes rendering the engine irreparable.

| diesel Power 2002 Ford F250 Power Stroke Diesel Rebuild long Block

If you're hip to the 7.3L Power Stroke segment, you know (or soon will) that connecting rod failures are more common in '99 to '03 7.3L engines that utilize powdered-metal rods-especially if the engine has been modified. When a 7.3L engine with powdered-metal rods is modified (usually making more than 400 hp at the wheels), premature rod failure can occur. The most common cause of powdered-metal rod failure in 7.3L Power Strokes is due to extremely high cylinder pressures. However, high rpm, engine overrev (where the piston and valves make contact), and spun rod bearings can lead to their demise as well. But powdered-metal rod failures aren't solely limited to the extreme performance crowd.

Recently, Loren Taylor of Diesel Tech experienced a powdered-metal rod failure in his '02 F-250 Super Duty. With only a set of mild injectors and conservative aftermarket tuning, he quickly ruled out any high-cylinder pressure scenarios. The cause? He concluded the failure was due to high-mileage metal fatigue. With more than 350,000 miles on the engine, the number five connecting rod cracked in the center of the beam and caused a chain reaction, where the rod split at the bearing as well. The rod failure also contributed to a damaged crankshaft, some valve-to-piston contact, and a damaged cylinder bore. With the engine disassembled, and the fact that Taylor was far from being done with his 7.3L workhorse, he opted to rebuild the engine and upgrade to forged-steel connecting rods.

| Here is a look at the number five connecting rod, which cracked along the center of the beam. This led to an additional break in the rod bearing, followed by some extreme valve slap on the piston. Since the truck only benefited from a set of small injectors and Edge tuning (known to be conservative), combined with the fact that more than 350,000 miles had been accumulated on the rotating assembly, we ruled in favor of high-mileage metal fatigue being the culprit.

Heading straight to an area Ford dealer, we inquired about its 7.3L DIT diesel engine overhaul kits. In addition to a laundry list of top and bottom end parts included in its kit, we ordered an OE crankshaft, high-pressure oil pump, two complete and pre-assembled cylinder heads, and of course, eight forged-steel connecting rods. Follow along as we upgrade and rebuild the 7.3L Power Stroke from the ground up using some of the best factory parts money can buy.

Powdered-metal rod vs. Forged-steel rod:

Powdered-metal rods were phased into the 7.3L's assembling process starting with engine serial number 1425747. But in order to deplete its inventory, Ford reverted back to the forged-steel units starting with engine serial number 1440713 and running through number 1498318. Engine serial number 1498319 until final production utilized powdered-metal rods.

| diesel Power 2002 Ford F250 Power Stroke Diesel Rebuild connecting Rod

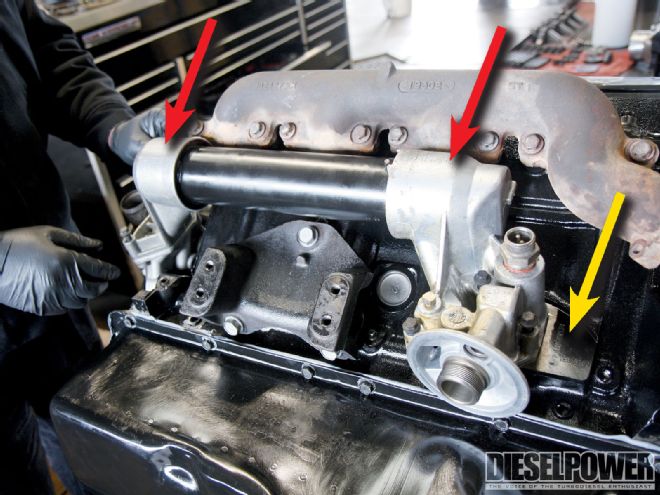

This may be why powdered-metal rods have been found in many '01 and even '00 model year trucks. Although you can also find your '99 to '03 engine's serial number on the driver-side valve cover, or on the rear oil cooler pad, concrete proof that you're dealing with powdered-metal connecting rods can be found by pulling the 5/16-inch pipe plug located on the block next to the oil cooler pad and taking a peek inside the crankcase.

In the photo shown, notice that the powdered-metal connecting rod's cap is secured using bolts (left), whereas the forged rod's cap is fastened with studs (this can be visible through the inspection hole in the crankcase mentioned above).

Parts and price list:

*All of our genuine Navistar part costs came from Pioneer Ford in Goodyear, Arizona.

PART:

PART NUMBER:

PRICE:

7.3L DIT diesel engine overhaul kit (0.030)

2C3Z-6R007-D

$1,102.55

Forged-steel connecting rods (8)

F4TZ-6V200-CARM

$487.76 ($25 core, each)

Crankshaft

3C3Z-6V303-AARM

$1,030.30 ($300 core)

Cylinder heads (2)

F5TZ-6V049-AARM

$1,382.44 ($300 core, each)

High-pressure oil pump

F81Z-9A543-CRM

$647.18 ($150 core)

Machine work and short-block assembly

N/A

$800 - $1,200 (estimate)

TOTAL 7.3L BUILD (labor not included)

$4,200.23 - $4,600.23 (core charges included)