| 2002 Dodge Ram 3500 Buildup scheid Diesel

When diesel owners in the Midwest seek the best performance money can buy, they come to a place where some very serious horsepower is made-Scheid Diesel. It's a business that, oftentimes, is directly linked to the most successful sled pull and drag race vehicles in diesel performance, not to mention some of the hottest running street trucks around. With this kind of reputation, and with our Midwest bureau being located so close to Scheid Diesel's Effingham, Illinois, location, we knew which shop would be turning up our '02 Dodge dualie. After all, some of the most powerful trucks in the country leave Scheid's shops on a daily basis.

The 24-Valve PlanWe'd already installed a TS Performance MVP module on our 24-valve Cummins ("Smokeless Horsepower", April '09) and were ready to turn the truck into the ultimate street and tow vehicle. First and foremost, we needed to address our truck's low fuel pressure issue-a common problem on '981/2 to '02 Dodges equipped with Bosch's electronically controlled rotary VP44 fuel injection pumps. Oftentimes, a failing factory lift pump will starve the injection pump-which results in both components failing. We planned to solve this problem by installing a FASS 150 series fuel system, followed by one of Scheid's Lightning VP44 injection pumps and a set of its Lightning injectors. From there, we planned to clean up our newfound fueling with one of its Lightning turbos.

BaselinesWhen Scheid strapped our 24-valve to its Mustang dyno for some baseline runs with the TS Performance pressure box turned up, the results told us that fuel pressure was not only weak, it fell to 0 psi at wide-open throttle. The lack of fuel was evident in our lower horsepower and torque numbers. At 248 hp and 714 lb-ft of torque at the wheels, the truck had lost 14 hp and 11 lb-ft since our last visit.

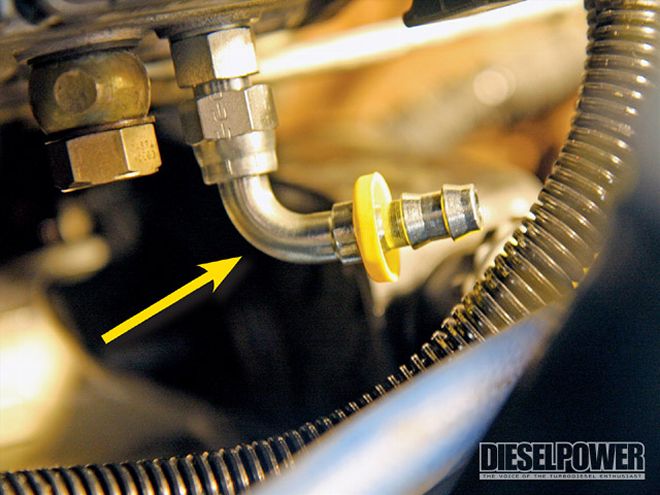

Fass System InstallKnowing the truck's fuel tank would need to be pulled, we arrived with just over a quarter tank of fuel. And, after all the hardware and tools for the job were laid out, the technicians at Scheid began the FASS fuel system install. The FASS pump and filtration unit was marked and mounted along the driver-side framerail and the tank was pulled.

Our truck had been retrofitted with an in-tank replacement lift pump from Dodge (which bypasses the engine lift pump). This required the guys at Scheid to drill a 11/4-inch hole in the tank and install the replacement suction tube included with the FASS kit. After that, the fuel tank was reinstalled and all return and supply lines were connected-then run from the tank, through the FASS system, and up to the injection pump. At this time, Scheid's technicians also removed the factory fuel filter reservoir assembly. Then the wiring was completed, the fuel system was primed, and the truck was started. The result: fuel pressure was 16 psi at idle.

Second Dyno RunOnce strapped back on the dyno, the fuel pressure held steady at 15 psi under wide-open throttle. Now we were ready to put our newfound fuel pressure to use.

Injector InstallIn order to see how well our factory injection pump could perform, we decided to install Scheid's Lightning injectors next. With the truck still on the dyno, the Scheid guys pulled the valve cover, removed the intake elbow, loosened the fuel lines, and pulled each fuel supply tube. From there, the injector hold-downs were removed and the stock injectors were pulled.

With the factory injectors out, each injector cup and fuel supply tube was cleaned, then six Lightning injectors were installed. Within an hour, the Scheid guys had swapped in our new injectors and were ready to see what the Dodge could do on the rollers.

Third Dyno RunOnce the truck was up to operating temperature, we made a couple of runs on the dyno-and the power started to build. We made 309 hp and 885 lb-ft-with EGTs never exceeding 1,250 degrees. Boost also increased to 33 psi (up from 28), while fuel pressure held steady at 15 psi. We did notice more smoke, which we expected with the new, higher-flowing Bosch nozzles that come with Scheid's Lightning injectors.

Injection Pump InstallThe last fuel modification was the addition of Scheid's Lightning VP44 injection pump. In order to gain access to the factory unit, the intake elbow and heater grid were removed, followed by all fuel line bracket bolts and nuts and the crankcase breather. Next, a special gear-pulling tool was used to disconnect the injection pump from the engine.

Once the new injection pump was mounted to the engine, all fuel lines were reconnected and double-checked. Then, the fuel system was primed by bump-starting the engine several times. After that, Scheid's technicians cranked the engine over for approximately 20 to 30 seconds and the Cummins came to life.

Fourth Dyno RunWe were shocked by how big a difference the new VP44 made. With the newfound fueling, we gained 75 hp and 255 lb-ft, which put us at 384 hp and 1,140 lb-ft at the wheels. Our factory Holset HX35 turbocharger's boost peaked at 35 psi, but it struggled to clean up much, if any, of the smoke-and EGTs crept up to 1,525 degrees.

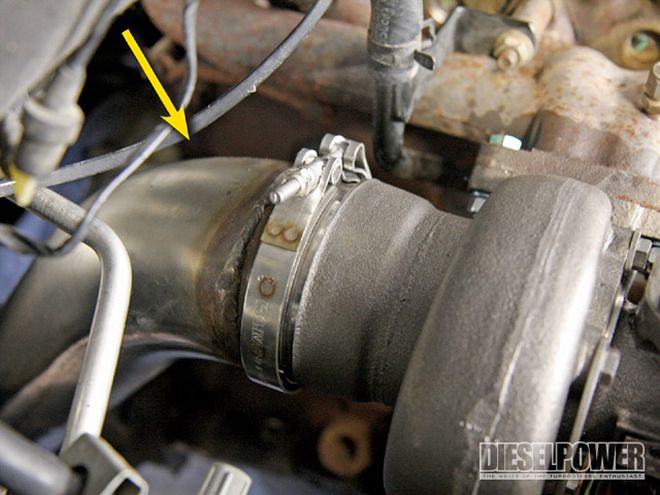

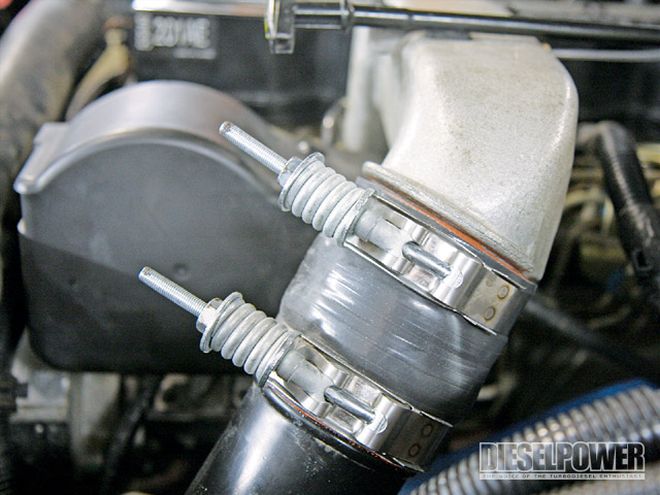

Turbo InstallWith plenty of fuel on tap, it was time to move more air through the Cummins mill. So, for the last time, the Scheid technicians tore into our 24-valve. With the air intake out of the way, they removed the exhaust flange bolts, unbolted the downpipe, disconnected the oil lines, and pulled the factory turbo.

Before installing our new Lightning turbo, it was pressure tested to make sure the wastegate would open at 38 psi. Then a new flange gasket was installed, followed by the turbo. The install was topped off with the addition of a new 4-inch downpipe.

Fifth Dyno RunAs expected, the Lightning turbo moved more air. The smoke cleared up slightly, fuel pressure maintained a 14-psi reading under full throttle, and EGTs cooled off nearly 150 degrees. Pushing just 33 psi of boost, all of this culminated in a very impressive 408 hp and 1,147 lb-ft final number.

ConclusionMake no mistake about it-the truck will downright haul now. To be more specific, in passing cars on the drive home, our Dodge zipped from 50 mph to 80 mph in a matter of seconds in Fifth gear. And while making our way through the NV4500 gearbox, we discovered that once the turbo lights-it's hang on time.

With all the low-end fueling the Lightning VP44 provides, you not only get that signature off-idle lope, but you get some seriously low-end grunt right from the get-go. Needless to say, after a 10,000-pound tow test, we were convinced Scheid had built us a truck that's not only a blast to drive on the street, but still capable of towing anything we need it to.

| 2002 Dodge Ram 3500 Buildup right Side Angle

10,000-pound Tow TestTo make sure our Dodge was still a versatile tow rig, we chose a humid, 90-degree day to take a testdrive with a 28-foot, 10,000-pound tandem axle toy hauler behind us. This was the make-or-break part of our buildup, because we still needed the truck to be able to haul everything it did before.

The results were quite impressive-not only did we get the load up and moving quicker, we were able to maintain our cruising speed in Fifth gear, on grades, and without EGTs sky-rocketing. In fact, on a 20-mile rolling hill stretch of highway running 65 mph, EGTs never exceeded 1,200 degrees.

With the help of Scheid Diesel, our 24-valve now has the best of both worlds-it's a multipurpose vehicle that can tow 10,000 pounds with ease, an economical daily driver, and of course, a much improved play toy on the street.

| 2002 Dodge Ram 3500 Buildup scheid Diesel

When diesel owners in the Midwest seek the best performance money can buy, they come to a place where some very serious horsepower is made-Scheid Diesel. It's a business that, oftentimes, is directly linked to the most successful sled pull and drag race vehicles in diesel performance, not to mention some of the hottest running street trucks around. With this kind of reputation, and with our Midwest bureau being located so close to Scheid Diesel's Effingham, Illinois, location, we knew which shop would be turning up our '02 Dodge dualie. After all, some of the most powerful trucks in the country leave Scheid's shops on a daily basis.

The 24-Valve Plan

| 2002 Dodge Ram 3500 Buildup scheid Diesel

When diesel owners in the Midwest seek the best performance money can buy, they come to a place where some very serious horsepower is made-Scheid Diesel. It's a business that, oftentimes, is directly linked to the most successful sled pull and drag race vehicles in diesel performance, not to mention some of the hottest running street trucks around. With this kind of reputation, and with our Midwest bureau being located so close to Scheid Diesel's Effingham, Illinois, location, we knew which shop would be turning up our '02 Dodge dualie. After all, some of the most powerful trucks in the country leave Scheid's shops on a daily basis.

The 24-Valve Plan

| 2002 Dodge Ram 3500 Buildup right Side Angle

10,000-pound Tow Test

| 2002 Dodge Ram 3500 Buildup right Side Angle

10,000-pound Tow Test