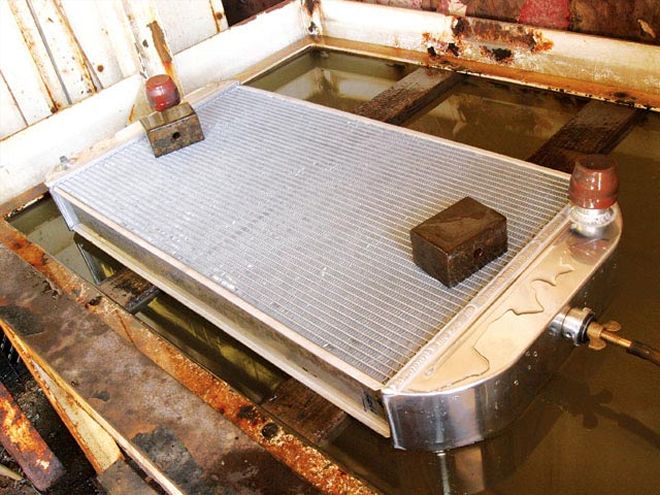

| mattsons Custom Aluminum Radiator side Angle

Serious motorheads are always striving to increase their engine's torque and horsepower. One concern when building a high-performance engine is heat. Heat is a major contributor to engine failure and a sufficient cooling system is vital to an engine's survival. The water pump, fan, and radiator are all essential components of the cooling system.The radiator is a major factor of the cooling equation.

The radiator is actually a heat exchanger, which circulates the engine's hot coolant through a radiator's cooling tubes that are surrounded by cooling air fins. This helps to dissipate the coolant's temperature. The early-model radiators were constructed from brass or copper and a typical brass or copper radiator used 3/8-inch-wide tubes. Conventional brass or copper radiators could weigh as much as 60 pounds.

Dan Dowdy of Street Rods by Dowdy in Dolan Springs, Arizona, was having some overheating and weight issues with his wild '37 Hudson Terraplane pickup. The Terraplane's power comes from a massive, Arias/Chevy 540ci 8.8L aluminum engine, with a BDS 1071 blower that produces nearly 1,000 hp, (engine only). When nitrous oxide is induced, the mighty Arias will crank out 1,500 hp. However, during cruise mode, Dan was having problems keeping his mega power cool.

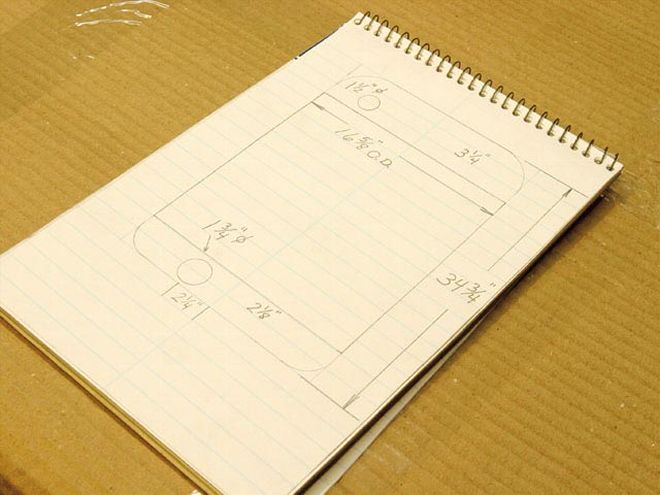

Dan consulted with Jack Mattson Jr., known as Mr. Cool in the aftermarket radiator industry, about his problem. Dan delivered his old-school brass/copper heavy radiator to Mattson's. Jack Mattson along with Jeff Hoyt, who is Mattson's number one designer, fabricator, and welder, examined Dowdy's first-generation radiator. They began recording shapes and dimensions. Paying close attention to the dimensions of the radiator would allow the new Mattson's custom radiator to drop right in.

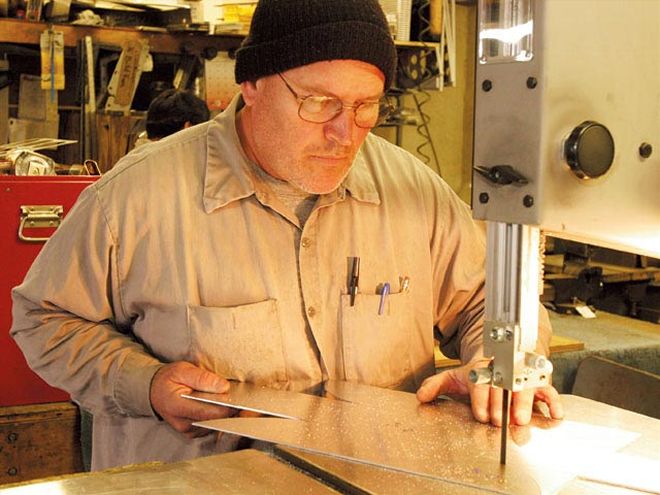

We thought it would be educational to show Jeff design, fabricate, and weld the new aluminum radiator. So follow along with the crew.

-

-

YOUR QUESTIONS ANSWERED

Time Spent Working: 16 hours

Difficulty of Job: Very Difficult

Material: Aluminum 60610 .0080 sheet

TOOLS USED:TIG-welder (Lincoln 255), 3/32-inch 4043 TIG-welding rod, bandsaw, 90-degree sheer, bender/brake, bead roller, assorted handtools, and a polisher

PARTS USED:Quantity/Description/Price1/custom aluminum radiator/$1,100.00

2/Spal electric fans, PN 3010204/$315.90

Total: $1,415.90

| mattsons Custom Aluminum Radiator side Angle

Serious motorheads are always striving to increase their engine's torque and horsepower. One concern when building a high-performance engine is heat. Heat is a major contributor to engine failure and a sufficient cooling system is vital to an engine's survival. The water pump, fan, and radiator are all essential components of the cooling system.The radiator is a major factor of the cooling equation.

The radiator is actually a heat exchanger, which circulates the engine's hot coolant through a radiator's cooling tubes that are surrounded by cooling air fins. This helps to dissipate the coolant's temperature. The early-model radiators were constructed from brass or copper and a typical brass or copper radiator used 3/8-inch-wide tubes. Conventional brass or copper radiators could weigh as much as 60 pounds.

Dan Dowdy of Street Rods by Dowdy in Dolan Springs, Arizona, was having some overheating and weight issues with his wild '37 Hudson Terraplane pickup. The Terraplane's power comes from a massive, Arias/Chevy 540ci 8.8L aluminum engine, with a BDS 1071 blower that produces nearly 1,000 hp, (engine only). When nitrous oxide is induced, the mighty Arias will crank out 1,500 hp. However, during cruise mode, Dan was having problems keeping his mega power cool.

Dan consulted with Jack Mattson Jr., known as Mr. Cool in the aftermarket radiator industry, about his problem. Dan delivered his old-school brass/copper heavy radiator to Mattson's. Jack Mattson along with Jeff Hoyt, who is Mattson's number one designer, fabricator, and welder, examined Dowdy's first-generation radiator. They began recording shapes and dimensions. Paying close attention to the dimensions of the radiator would allow the new Mattson's custom radiator to drop right in.

We thought it would be educational to show Jeff design, fabricate, and weld the new aluminum radiator. So follow along with the crew.

| mattsons Custom Aluminum Radiator side Angle

Serious motorheads are always striving to increase their engine's torque and horsepower. One concern when building a high-performance engine is heat. Heat is a major contributor to engine failure and a sufficient cooling system is vital to an engine's survival. The water pump, fan, and radiator are all essential components of the cooling system.The radiator is a major factor of the cooling equation.

The radiator is actually a heat exchanger, which circulates the engine's hot coolant through a radiator's cooling tubes that are surrounded by cooling air fins. This helps to dissipate the coolant's temperature. The early-model radiators were constructed from brass or copper and a typical brass or copper radiator used 3/8-inch-wide tubes. Conventional brass or copper radiators could weigh as much as 60 pounds.

Dan Dowdy of Street Rods by Dowdy in Dolan Springs, Arizona, was having some overheating and weight issues with his wild '37 Hudson Terraplane pickup. The Terraplane's power comes from a massive, Arias/Chevy 540ci 8.8L aluminum engine, with a BDS 1071 blower that produces nearly 1,000 hp, (engine only). When nitrous oxide is induced, the mighty Arias will crank out 1,500 hp. However, during cruise mode, Dan was having problems keeping his mega power cool.

Dan consulted with Jack Mattson Jr., known as Mr. Cool in the aftermarket radiator industry, about his problem. Dan delivered his old-school brass/copper heavy radiator to Mattson's. Jack Mattson along with Jeff Hoyt, who is Mattson's number one designer, fabricator, and welder, examined Dowdy's first-generation radiator. They began recording shapes and dimensions. Paying close attention to the dimensions of the radiator would allow the new Mattson's custom radiator to drop right in.

We thought it would be educational to show Jeff design, fabricate, and weld the new aluminum radiator. So follow along with the crew.