| This is the deluxe 502/502 package (minus the plug wires) after assembly and just before it was installed onto Westech's dyno. No, the trick electric water pump isn't part of the package. Wouldn't that be nice if it was?

It's a fact that the easiest and cheapest way to build monster horsepower and torque numbers is with a large-displacement V-8 engine. These days, you don't need an exotic and expensive engine combination, nor do you need a high-compression engine, to build big-time power. Pump gas-friendly powerplants are now reliably cranking out the ponies that were at one time reserved only for race engines running high-octane fuel, thanks to advancements in engine block and cylinder head design. Using proven large-displacement technology, which has been perfected since the early 1960s, will routinely yield the power you seek, especially when you rely upon the engineers at General Motors for the building blocks. With this in mind, we power fiends here at Sport Truck magazine took a brand-new GM Performance Parts 502-cid crate engine and proceeded to tweak, test, and add basic performance parts to the bone-stock engine until we were satisfied with the results. Then we let the dogs out, adding larger cylinder heads and a roots-type supercharger to the mix, ending up with an engine that made more power than we knew what to safely do with on 91 octane fuel. In this, the first installment of a three-part crate motor power building series, we'll gather up baseline dyno information on the engine in its stock configuration as well as perform the first round of basic modifications and test the results.

The Deluxe PackageGM's sixth-generation crate engines are available in various combinations and displacements, from 454 cid all the way up to 572 cid. Our deluxe ZZ502/502 crate motor came shipped with the short-block pre-assembled. The bottom end is impressive to say the least. The cast-iron block features 4.4460-inch Siamese bores that are stuffed with forged-aluminum pistons. Forged-steel connecting rods with 7/16-inch bolts push the pistons, and they swing on a 4-inch-stroke forged-steel crankshaft. The rotating assembly is held in place by four-bolt main bearing caps.

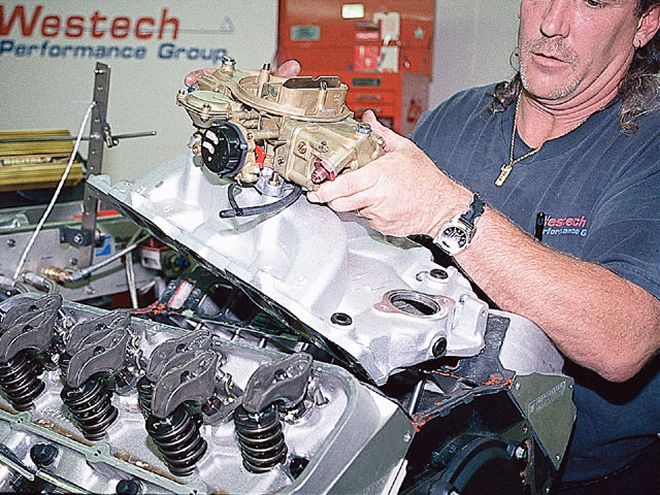

Westech Performance Group's resident engine guru and dyno cell technician, Steve Brul, assembled the top end of the engine with ease. The ZZ502/502 deluxe package breathes through a set of aluminum, rectangular-port cylinder heads. The heads (PN 12363390) feature large 2.25-inch stainless-steel intake valves and 1.88-inch stainless-steel exhaust valves. The valves have 11/32-inch stems, and the heads also come with high-performance valve springs, seals, caps, and keys. With a combustion chamber volume of 110 cc's, GM rates this package with a 9.6:1 compression ratio - perfect for the measly 91 octane fuel that we are forced to buy in California.

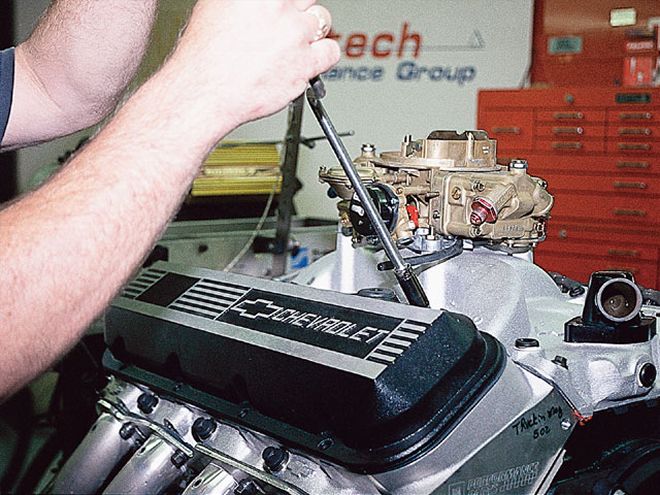

The rest of the high-performance package is just as impressive. An aluminum dual-plane intake manifold is teamed with a four-barrel Holley 850-cfm vacuum secondary carburetor. A reliable GM electronic high-energy ignition distributor with built-in coil provides the spark to 8mm shielded plug wires and #4 Rapid Fire spark plugs.

In its stock configuration, this motor performed way beyond our expectations and exceeded the numbers advertised by GM. On Westech Performance Group's Superflow dyno, the 502 maxed out with 534 hp at 5,500 rpm and 569.6 lb-ft torque at 4,100 rpm. The motor pulled extremely hard, never making less than 500 lb-ft torque from 2,500 rpm all the way up to 5,500 rpm. The numbers were good and left us with a positive outlook on the work that lay ahead.

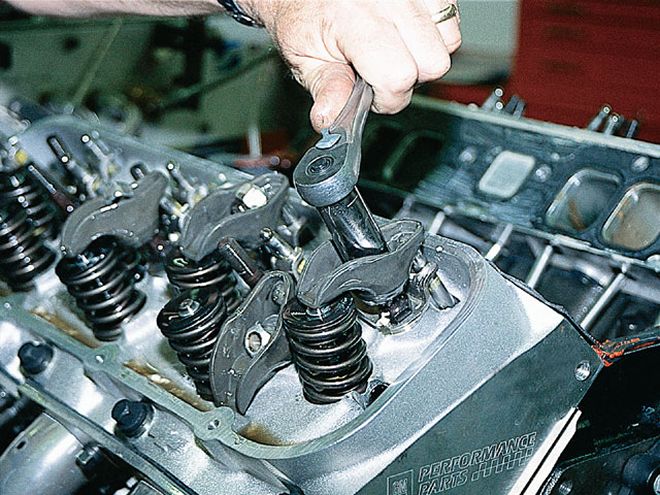

Easy Does ItThe first step in our master plan called for simple and easy modifications to the top end of the engine, where we knew a few extra ponies lay in wait. The first stop on our runaway horsepower train was to Comp Cams for a new roller valvetrain. The factory camshaft measured as follows: At 0.050 inches of lift, the intake valves peaked at 0.224 and the exhaust at 0.234; gross valve lift came in at 0.527 on the intake side and 0.544 on the exhaust side. This hydraulic cam offered a good compromise of driveability and power with a very smooth idle.

Comp Cam's answer to GM's cam choice came in the form of an Extreme Energy XR288HR hydraulic roller camshaft. This profile would really wake up our engine, while still maintaining a smooth idle and driveability, because the engine would still make enough vacuum at idle to operate a truck's power braking system. Another bonus with this camshaft is that there isn't any need to re-adjust the valve lash after installation because of the hydraulic roller lifters used. The XR288HR specs out like this: At 0.50 lifter rise, the intake has a duration of 0.236 and the exhaust, 0.242; gross valve lift occurs at 0.521 inch for the intake valves and 0.540 for the exhaust; and lobe centerline is 110 degrees.

Along with the cam change, the rest of the valvetrain received upgrades to reduce friction and increase durability. The stock stamped-steel rocker arms were tossed in the trash in favor of Comp Cam's Magnum 1.7-ratio roller rockers. The pushrods were also upgraded to 3/8-inch Comp Cams units, and a double-roller timing chain was also thrown into the mix.

Next, Brul buttoned up the engine with a new Edelbrock Performer RPM Air Gap intake manifold. This dual-plane design is perfect for a street engine and will help pump up the power from idle all the way to 6,500 rpm. The Air Gap design helps cool the intake charge by allowing air to circulate beneath the plenum when the truck is at cruising speeds.

To feed the rat with a precise amount of fuel, we chose a new Race Demon 850-cfm carburetor from Demon Carburetion. The Race Demon carb has several key features that make tuning much easier. First off, the metering blocks are built into the fuel bowls, which eliminates an extra set of gaskets and potential leaks. This makes changing the jets a clean and easy task.

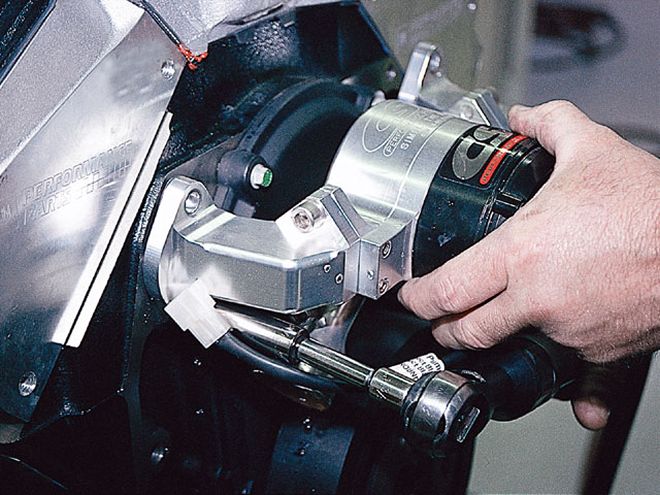

Finally, an MSD Ignition system was installed to take control of lighting the fire within the 502. The Pro Billet distributor and 6BTM spark box offer great flexibility, precise and powerful spark, and the ability to upgrade and add external plug-and-play modules. In most cases, we would have chosen MSD's 6AL ignition box, but the BTM box offers a boost retard timing circuit that will be a critical and much-appreciated feature once we install the supercharger onto this engine.

The PayoffWith these minor alterations to the top end of the engine, we were able to push the big Rat motor to build more than 570 hp and 620 lb-ft of torque. This was an increase of 37 hp and 52 lb-ft of torque over our baseline dyno testing. More importantly, though, the engine was now pumping out more torque across the board, with numbers more than 600 lb-ft from 3,800 rpm to 4,800 rpm. That's a whole bunch of punch that you'll feel in the seat of your pants when towing a load or merging onto the freeway.

502-CID STOCK CRATE MOTOR RPM POWER TORQUE 3,000 {{{323}}}.5 566.3 3,500 374.1 561.4 4,000 432.7 568.2 4,500 480.8 561.1 5,000 520.1 546.4 5,500 534.0 509.9 Max Power = 534 hp @ 5,500 rpm Max Torque = 569.6 lb-ft @ 4,100 rpm 502-CID MODIFIED CRATE MOTOR RPM POWER TORQUE 3,000 338.8 593.1 3,500 392.9 589.6 4,000 473.1 621.2 4,500 522.7 610.1 5,000 550.5 566.9 5,500 571.8 546.1 Max Power = 571 hp @ 5,500 rpm Max Torque = 621.2 lb-ft @ 4,000

| This is the deluxe 502/502 package (minus the plug wires) after assembly and just before it was installed onto Westech's dyno. No, the trick electric water pump isn't part of the package. Wouldn't that be nice if it was?

It's a fact that the easiest and cheapest way to build monster horsepower and torque numbers is with a large-displacement V-8 engine. These days, you don't need an exotic and expensive engine combination, nor do you need a high-compression engine, to build big-time power. Pump gas-friendly powerplants are now reliably cranking out the ponies that were at one time reserved only for race engines running high-octane fuel, thanks to advancements in engine block and cylinder head design. Using proven large-displacement technology, which has been perfected since the early 1960s, will routinely yield the power you seek, especially when you rely upon the engineers at General Motors for the building blocks. With this in mind, we power fiends here at Sport Truck magazine took a brand-new GM Performance Parts 502-cid crate engine and proceeded to tweak, test, and add basic performance parts to the bone-stock engine until we were satisfied with the results. Then we let the dogs out, adding larger cylinder heads and a roots-type supercharger to the mix, ending up with an engine that made more power than we knew what to safely do with on 91 octane fuel. In this, the first installment of a three-part crate motor power building series, we'll gather up baseline dyno information on the engine in its stock configuration as well as perform the first round of basic modifications and test the results.

The Deluxe Package

| This is the deluxe 502/502 package (minus the plug wires) after assembly and just before it was installed onto Westech's dyno. No, the trick electric water pump isn't part of the package. Wouldn't that be nice if it was?

It's a fact that the easiest and cheapest way to build monster horsepower and torque numbers is with a large-displacement V-8 engine. These days, you don't need an exotic and expensive engine combination, nor do you need a high-compression engine, to build big-time power. Pump gas-friendly powerplants are now reliably cranking out the ponies that were at one time reserved only for race engines running high-octane fuel, thanks to advancements in engine block and cylinder head design. Using proven large-displacement technology, which has been perfected since the early 1960s, will routinely yield the power you seek, especially when you rely upon the engineers at General Motors for the building blocks. With this in mind, we power fiends here at Sport Truck magazine took a brand-new GM Performance Parts 502-cid crate engine and proceeded to tweak, test, and add basic performance parts to the bone-stock engine until we were satisfied with the results. Then we let the dogs out, adding larger cylinder heads and a roots-type supercharger to the mix, ending up with an engine that made more power than we knew what to safely do with on 91 octane fuel. In this, the first installment of a three-part crate motor power building series, we'll gather up baseline dyno information on the engine in its stock configuration as well as perform the first round of basic modifications and test the results.

The Deluxe Package