Diesel injectors fail because of two main reasons. The first has to do with the mechanical soundness of the injector structure, and the second has to do with the quality of the fuel running through the injector. In order to get an understanding of the workings of an injector (and what actually makes them fail), we contacted Exergy Engineering. The company supplied us with many of the images of failed injectors you see here, taken with a microscope, to help you to keep this damage from happening to your diesel.

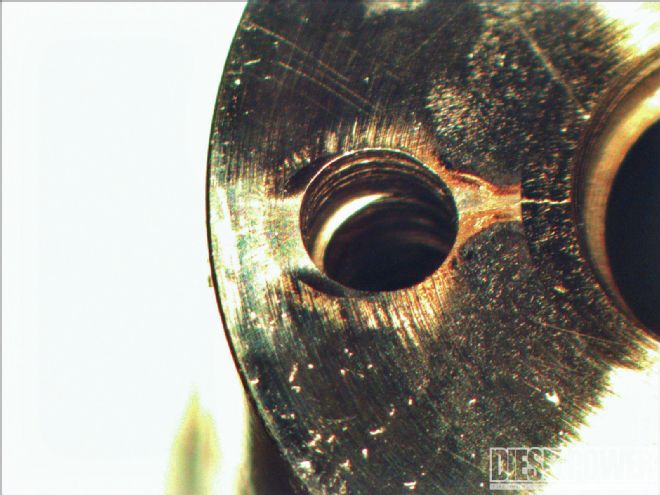

| This is what a washed-out common-rail injector ball seat looks like. Without a flush surface to seal against, the injector will not shut off, and piston damage is usually the result. Aggressive tuning and debris in the fuel is usually the culprit. All these examples are from actual injectors Exergy Engineering took in to test.

To find out as much as we could about the fuel side of the equation, we contacted Afton Chemical, a company that specializes in fuel additives. Afton has 85 years worth of experience working with OEMs and fuel companies. By leveraging both of these companies’ expertise, we hope to make fuel injector problems a thing of the past.

Is There a Fuel Injector Problem?

If proper maintenance is performed and problematic practices are avoided, the vast majority of diesel owners will go thousands of trouble-free miles without a problem. If you’re a diesel owner with an older engine (pre-common-rail), most of this article (besides the general maintenance advice, like changing your fuel filter regularly) doesn’t apply to you. This is because older diesel injection systems only use about 1⁄2 the fuel pressure modern engines do, and older injectors send the fuel through much larger passages.

Why is there such a difference with common-rail injectors? Modern common-rail diesel injectors can fire two or three times per engine cycle—this doubles the wear on the injector compared to diesels of the past. To tell if there is a problem with common-rail injection systems fueled with ultra-low-sulfur diesel (ULSD) fuel, we need to know how many injectors have failed since its introduction. The feedback we get from our readers and online reports of failures suggests there’s always room for improvement in our fuel, too.

Mechanical Failures

According to Exergy Engineering, injectors fail because of five major reasons. We listed them here, along with the indicators of the problem, the causes, and how it’s prevented.

| Remember, all these pictures are taken under a microscope. To the naked eye, an injector may seem fine, when in reality it is not. The shim on the right was likely damaged during injector assembly.

Failure: High Internal Leakage or Return Flow

Indicators:

1. Engine is hard to start (requires increased cranking time in order to start)

2. Low common-rail pressure codes

Causes:

Worn injector ball seat

Leaking cross feed tubes (Cummins)

Blown internal high-pressure seal

Incorrect nozzle needle clearance

Cracked nozzle body

Cracked injector body

Prevention:

Keep fuel system clean, change fuel filters, purchase fuel from reliable sources, avoid filling from portable construction fuel tanks

Avoid overly aggressive tuning that increases rail-pressure and injector pulse widths and do not remove pressure-limiting devices from the system

Do not use remanufactured or aftermarket injection components that are not properly designed or manufactured

Reject all fuel system replacement parts that have metallic burrs

Use only Bosch nozzles, as they are reported to have superior crack resistance

Do not mix nozzle needles, because they are matched to the body and moving one from another can result in excessive clearance or improper needle lift

Failure: No Injection

Indicators:

Balance rates are high (positive), indicating fuel is being added to the cylinder because the computer thinks the fuel injector is not flowing enough. The computer makes this decision based on the two things it knows: the rotational speed of the crankshaft and the amount of fuel delivered. If the crankshaft is not spinning as fast as the computer thinks it should (or is spinning faster than it should), fuel (via pulse width) is added or taken away to even out crankshaft acceleration from each injector firing.

| Here is a blown high-pressure seal found inside a common-rail injector.

Cylinder contribution low (cylinder contribution test is performed by shutting off one injector at a time while taking note of drop in engine RPM)

ECU fault codes

Causes:

Debris or rust in the injector plugging the nozzle

Armature and/or nozzle needle stuck

Bad stator (rare)

Loss of cylinder compression or other mechanical problem

Prevention:

Keep fuel system clean, change filters, purchase fuel from reliable sources, and avoid filling from portable construction fuel tanks or questionable sources

Do not use remanufactured or aftermarket components that are not properly designed or manufactured

Reject all fuel system replacement parts that have metallic burrs

Avoid tying the returns from multiple high-pressure pump kits and injectors to a single return line; excessive return pressure acting on the injector stators can lift them (and in extreme cases blow them off), shutting the injector down

If a long storage time of the vehicle is expected, arrange to have it started on occasion to prevent internal varnishing and corrosion of internal components; aftermarket fuel additives specifically designed for stabilizing diesel fuel should also be added

Failure: Excessive Injection

Indicators:

Excessive smoke at idle, poor running, and banging

| Here is body damage from an improper assembly job.

Balance rates high (negative), indicating the computer is removing fuel from the injector

Cylinder contribution test is high, meaning as each injector is activated one will increase engine rpm more than normal

Excessive exhaust gas temperature

Engine damage from excessive heat or hydraulic lock from excessive fuel in the cylinder

Causes:

Worn ball seat in injector or poor end of injection cut off

Nozzle needle seat worn or damaged

Debris in control system of injector, which holds it open

Debris in nozzle needle seat holding it open

Cracked nozzle from overpressure, or overheated nozzle from improper installation of injector

Prevention:

Replace worn and high-mileage injectors; do not use these injectors as a foundation for building a high-output injector set

Replace worn nozzles

Keep fuel system clean, change filters, purchase fuel from reliable sources, and avoid filling from portable construction fuel tanks or questionable sources

Reject all fuel system replacement parts that have metallic burrs

Do not use remanufactured or aftermarket components that are not properly designed or manufactured

Failure: Incorrect Injection Rate

Indicators:

Rough running and poor cylinder balance

| Rebuilding injectors requires surgery-level cleanliness. Even one piece of microscopic lint in the control orifice can create an injector that’s unable to shut off. This is one of the reasons so few companies can rebuild common-rail injectors.

Large cylinder-to-cylinder exhaust temperature variation

Causes:

Poor nozzle flow balance

Nozzle needle lift incorrect (mixed or missing parts)

Partially plugged nozzle

Wire-brushed nozzles

Prevention:

Keep fuel system clean, change filters, purchase fuel from reliable sources, and avoid filling from portable construction fuel tanks or questionable sources

Reject all fuel system replacement parts that have metallic burrs

Do not use remanufactured or aftermarket components that are not properly designed or manufactured

Ensure injectors are serviced or purchased from a reliable source

Do not clean nozzles with a wire brush

Failure: Incorrect Injection Timing and Duration

Indicators:

Rough running, poor cylinder balance, and knocking

Piston damage

Large cylinder-to-cylinder exhaust temperature variation

Causes:

Ball seat wear

Incorrect injector assembly, parts mixed, or parts missing

Injector needle lift increased to increase output

Prevention:

Replace worn injectors

Ensure injectors are serviced, tested, and purchased from a reliable source

Diesel Fuel Failures

According to Afton Chemical’s North American Marketing Manager, David Cleaver, there are three major causes of injector failure associated with the properties of the fuel itself: excess wear, abrasion, and deposits.

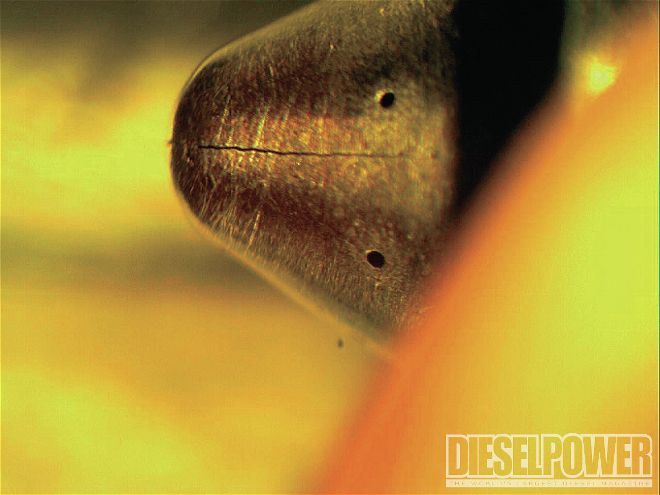

| Here is a non-Bosch-produced injector nozzle with its tip blown off. Making parts to survive in these roles is tough, and some aftermarket companies struggle to match Bosch’s materials and heat treatment processes.

Excess Wear

One mode of injector failure is excess wear. Prior to 2006, diesel fuels in the United States contained relatively large amounts of sulfur. This sulfur is found in the crude oil that gets refined into diesel fuel. The sulfur in the fuel was used as a natural lubricant for the fuel system. Ultra-low-sulfur diesel (ULSD) was gradually introduced into the United States because sulfur ruins diesel particulate filters (DPFs). Ultra-low-sulfur diesel is now mandated in all diesel fuel segments, including on-highway, off-highway, and railroad. Ultra-low-sulfur diesel has a maximum allowable sulfur content of 15 parts per million (ppm). As refiners removed this sulfur, the lubrication benefits went away as well. As a result, diesel fuel refineries now put additives in the fuel to restore lubricity.

| This is another example of poor nozzle quality due to bad materials.

The standard for measuring this lubricity is called the High Frequency Reciprocating Rig (HFRR) Test, ASTM D-6079, which measures the size of a wear scar between two metal surfaces lubricated with the fuel. The less lubrication the fuel provides, the larger the wear scar. The maximum allowable wear scar in the United States is 520 microns (460 microns in Canada). Many fuel distributors add additional lubricity improvers to the fuel to limit premature wear.

Abrasion

While fuel lubricity is an important factor in determining the wear characteristics of the fuel injection system, it is not the only fuel-related cause of excess wear. The other potential cause of premature injector failure (due to wear) is caused by abrasion. All fuels contain small amounts of impurities—even the highest-quality diesel fuels. Some of these impurities include very small (a few microns in size) particles that can pass through even the tightest onboard vehicle filters. If the fuel contains a large amount of these small, insoluble particles, over time they can abrade the injectors as they pass through during normal engine operation. In extreme cases, this abrasion can significantly alter the fuel spray pattern, causing reduced engine performance. In severe cases, it can even lead to injector failure. Good housekeeping practices by the fuel supplier, and good fuel filtration, can reduce the damage caused by this abrasion.

| We’ve seen what a good and even spray pattern looks like; here’s an example of what you don’t want.

Deposits

While excess wear (whether caused by poor fuel lubricity or abrasion) is important to consider when discussing the cause of injector failure, Afton Chemical says the major reason for injector failure today is due to excessive buildup of deposits. There are two major types of these deposits: external injector deposits and internal injector deposits.

| Nozzle needles can also wear out. This one was failing due to high mileage.

External injector deposits are generally caused by incompletely burned fuel that builds up around the injector holes. These deposits are referred to as coking deposits. While in most cases these deposits may not lead to injector failure, they can build up enough to disrupt the fuel spray, which leads to less efficient fuel combustion. This is often observed by the vehicle operator as a noticeable loss in power or lost fuel economy. Detergent additives have been used quite successfully to help control these external deposits and restore the injector to its most efficient performance—restoring both the lost power and lost fuel economy caused by the buildup of these external deposits.

Internal Diesel Injector Deposits

In the last five years, a new type of injector deposit has begun to appear, according to Afton Chemical. This deposit does not form on the external tips of the injectors, but rather on the internal parts, such as the injector needles and pilot valves. These deposits often look similar to the coking deposits (dark brown in color) but can also be very light, almost grayish to off-white in appearance. While they can form in virtually any type of diesel engine, they typically only cause operational issues in the newer engines with precision injection systems.

| This injector failed because of debris and rust in the fuel system.

Engine manufacturers are now offering injection systems that operate at very high injection pressures (greater than 30,000 psi in some cases) that supply fuel to all injectors through a common fuel rail. These engines are often referred to as high-pressure common-rail (HPCR) engines. They were designed to supply the demand for more powerful diesels while still meeting ever-tightening emission regulations.

Injection pressures near 30,000 psi create a very fine fuel mist spray in the combustion chamber, resulting in more complete burning of the fuel. This more complete fuel burning yields lower emissions and can also improve fuel economy. In order to maintain these high injection pressures, the injector assemblies have been highly engineered and have very tight clearance tolerances, sometimes as small as 1 to 3 microns (a human hair is typically 70 to 100 microns thick). So you can imagine it wouldn’t take much material depositing on these parts to cause poor injector needle actuation, leading to poor engine performance. In extreme cases, these deposits can lead to complete sticking or seizing of the injector needles, particularly after the vehicle has been shut down and the engine has been allowed to cool.

As these internal deposits build up, they can cause the same symptoms as the more traditional external coking deposits, namely lost power and reduced fuel economy. In extreme cases in which the injectors begin to completely stick, they can lead to excessive vehicle downtime and high maintenance costs.