What do you get when you combine an electronics company with one that specializes in fuel injection and custom fabrication? In this case you get TS Performance and Scheid Diesel joining forces to bring us an industry first: a compound turbocharger system that utilizes a variable -geometry, high-pressure turbo. Designed for the common-rail 5.9L Cummins, it combines two heavy-duty, OE-quality turbos into one aftermarket application. With BorgWarner supplying its tried-and-true S400 and state-of-the-art VTG S300, TS Performance controlling the variable-geometry turbo, and Scheid designing and building the kit, the marketplace benefits from a well-crafted, dyno-proven, bolt-in system for ’03 to ’07 Dodge Rams.

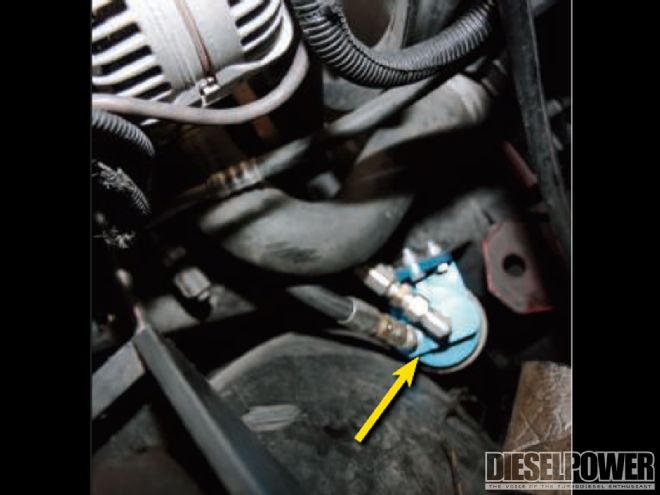

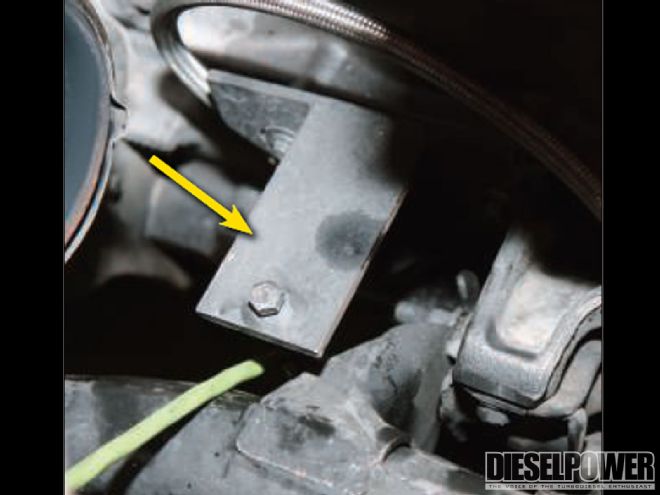

| Scheid Diesel’s new compound turbocharger system (LIGHTNING-VGT-TWIN-KIT) comes with everything you need to turn your 5.9L common-rail into the ultimate street truck. The all-inclusive kit includes: BorgWarner S300BV (A), Pacbrake oil filter relocation kit (B), BorgWarner S400 (C), 45-degree intake couplers and intake extension (D), air filter (E), intercooler boots (F), S300BV compressor outlet (G), atmosphere-to-manifold turbo intake tube (H), intercooler tube (I), hot pipe (J), ATS Diesel exhaust manifold (K), and S400 support bracket (L). Although not pictured here, a controller for the variable-vane turbo, 5-inch downpipe, automatic transmission heat exchanger reroute (for 48RE trucks), and all hardware is also included. The VTG controller offers truck owners the ability to make a (plus or minus) 20 percent change in the pre-programmed setting to fine tune the high-pressure turbo for their particular driving style.

On a recent trip to Scheid Diesel’s Terre Haute, Indiana, facility, we saw the fit and finish of this system firsthand as it was being installed on TS Performance’s ’06 Dodge Ram 2500. While there, we realized how beneficial the use of variable-geometry technology will be in the diesel aftermarket. Imagine driving the perfect truck: one that spools instantly, pulls great up top, and doesn’t smoke a lick. Whether it’s drag racing, daily driving, or towing, this type of compound turbo arrangement maximizes performance in all areas. Read on to see what the future of twin turbocharging may hold.

OE Concept, Adopted By The Aftermarket

The idea of combining a variable-geometry turbo and a large, fixed-geometry unit in a compound arrangement is nothing new. In fact, BorgWarner already brought this variable, two-stage turbo system (its V2S configuration) to the OE market for the 6.4L Power Stroke. For those who don’t know, the ’08 to ’10 6.4L Power Stroke engine benefited from instant spool-up and lower emissions from the factory, thanks to the V2S configuration. In the aftermarket, the 6.4L’s turbo arrangement, which was thought to be somewhat small in size (a 52mm variable-turbine-geometry unit combined with a 65mm low-pressure, fixed-geometry unit), could support more than 550 hp at the wheels.

| Based on BorgWarner’s popular S300 turbo, the S300BV features its electronically controlled variable-turbine-geometry (VTG) exhaust housing and serves as the high-pressure unit in Scheid’s compound kit (meaning it takes care of bottom end response, whereas the low-pressure turbo takes over at higher engine speed). The S300BV’s turbine housing ranges from near closed (for takeoff and quick response) to 24.1 cm (under wide-open throttle). The titanium compressor wheel features BorgWarner’s extended-tip technology, and its inducer measures 62 mm. The S300BV alone is capable of flowing 72 pounds of air per minute (roughly 1,030 cfm).

Although the same principle applies here, the difference with Scheid’s kit is it’s designed to maximize performance for trucks that have already been fitted with items like larger injector nozzles, stroked single or dual CP3 injection pumps, aftermarket fuel systems, and aggressive tuning. And the flexibility the variable-geometry turbo provides makes this system work in 400hp trucks as well as ones making 800 hp. Thanks to the efficiency of the VTG turbo coupled with EFILive tuning, anyone will be able to build a snappy-yet-smooth, smokeless-but-powerful truck that can still tow anything or perform at the dragstrip.

| A larger BorgWarner turbo from the S400SX line takes care of the low-pressure stage. The large-frame S400 is known for its great flow characteristics and rugged durability in the aftermarket (often referred to as an S480 when equipped with an 80mm compressor wheel). The S400SX also features BorgWarner’s extended-tip compressor wheel technology (for a broader compressor map) but utilizes a cast-aluminum wheel with an 80.3mm inducer. Its ultra-high-flow, 96mm (inducer) turbine wheel is the largest offered in this 1.32 A/R, non-wastegated turbine housing. On its own, this particular S480 will flow 120 pounds of air per minute (approximately 1,700 cfm).