When you drive a heavy-duty truck like an F-550, or even an F-350, Ram 3500, or a big GMC, you just expect everything to work…like forever, right? Then, one cold morning, you turn the key and there is that ominous “click, click, click.” Could be the starter. Could be the batteries—especially if you have a newer diesel with common-rail direct injection and glow plugs. When the “Wait to Start” light comes on, those little glow plugs that preheat the chambers above the pistons in Power Stroke and Duramax engines are, in essence, a dead short, sucking any surface charge off your batteries if they are already low. Now, in the case of our 7.3L Power Stroke with the HEUI injection system, those same batteries need enough power reserve to spin the motor at 150 rpm—fast enough for the high-pressure oil pump to produce around 400 to 600 psi. Additionally, the batteries need to have enough amps left to feed the IDM (injector driver module), which converts 12 volts to 115 DC volts to actually pop the injectors. Ford did not switch to the common-rail until 2008.

| We installed two fresh Group 34/78-PC1500 Odyssey Extreme batteries in our ’99 Ford Super Duty.

That’s asking a lot of a little starter on a cold morning—or a pair of batteries that are not fully charged, maybe because the alternator is getting tired. And then again, the whole problem, more often than not, is just a bad or corroded ground wire. Gas burners have it a little easier starting, but their electrical system is just as important.

We had Ken Imler Diesel Performance inspect the electrical system on our 1999 Ford Super Duty in preparation for a lengthy expedition, The Trans-Eurasian Odyssey, which would take us from Lisbon, Portugal to Shanghai, China through 26 countries following the legendary Silk Road—an adventure we expect will take at least three years. We could not afford to take any chances with any part of that critical system.

| All battery cable connections were checked and cleaned.

Starting at the top, we installed two fresh Group 34/78-PC1500 Odyssey Extreme batteries. Odyssey batteries use absorbed glass mat (AGM) technology to offer (in one box) the advantages of both a high-powered starting battery and a deep-cycle battery, good for up to 400 cycles at 80 percent depth of discharge. That’s sort of like a sprinter and a long-distance runner in one. Because Odyssey plates are made of pure virgin lead (unlike the lead alloy in most batteries), they can pack in more plates. More plates means more plate surface area—and much more power. They deliver twice the overall power of conventional batteries, with a life designed for 8 to 12 years.

While we may think of our trucks as only mechanical devices, they also have many different electronic parts that resemble a personal computer more than a vehicle. All these little computers draw power as they remember your personal seat and outside mirror positions, and your favorite radio stations. Most trucks built from the early ’90s contain a small component called a powertrain control module (PCM) that electronically controls parts and runs diagnostic tests. It only makes sense to have the best batteries you can afford—especially if you plan on keeping your eight-lug truck for a few years.

There are many sizes of batteries, each with its own power rating and configuration. For example, Odyssey makes at least 18 models, some with side posts and others with the more common top posts. Some models have both. When you are installing dual batteries, like most diesel trucks require, it’s always a good idea to use two of the same type and size. We also checked all cables and auxiliary wires leading to accessories, like our winch and driving lights, making sure the ground wires were clean and tight.

No matter how great your batteries are, they are useless if they are not being properly charged and regulated. Our truck was ordered with the dual alternator ambulance package. The primary alternator charges the starting batteries, and the auxiliary unit feeds four Odyssey Group 34 batteries in the camper. In case you wonder why we use the same size batteries in the engine compartment as those in the camper, it allows us to replace a starting battery under the hood should one fail. Also, unlike some of the huge batteries in RVs today, the Group 34 is fairly common all over the world.

Imler Diesel removed our alternators, and we took them over to S&N Auto Electric in Sacramento where expert technician Nimo Sahota completely reconditioned them. After cleaning and sandblasting the cases, all critical parts were replaced. These included heavy-duty rectifiers and diodes, heavy-duty (NTN) bearings, new heavy-duty brush holders, brushes and regulator, and a high-output stator on our auxiliary unit that charges the camper battery bank through an external Balmar regulator.

Sammy Rai, owner of S&N Auto Electric, explained that newer alternators like ours run cooler than earlier models because they actually have internal fans on both the front and back of the rotor assembly. He also cautioned that often alternators are just grounded to the mounting bracket. Sometimes corrosion can build up between the front and back of the case, so it was very important to have a good ground strap from the back of the case to the engine block. He emphasized that good, solid, clean ground is as important as a clean battery connection. This can significantly extend the alternator’s life.

The latest-technology computerized test machine was used to spin up the alternators and check for operating voltage, output, and amperage at various speeds. The machine simulates on-truck functions, including alternator turn-on speed, voltage saturation point, dash-light function, load response control, soft-start function, and input/output signal response at performance curve outputs from 1,000 to 6,000 rpm. Readouts showed 160 amps going to the starting batteries, and 200 amps from our auxiliary alternator feeding the house bank of Odysseys.

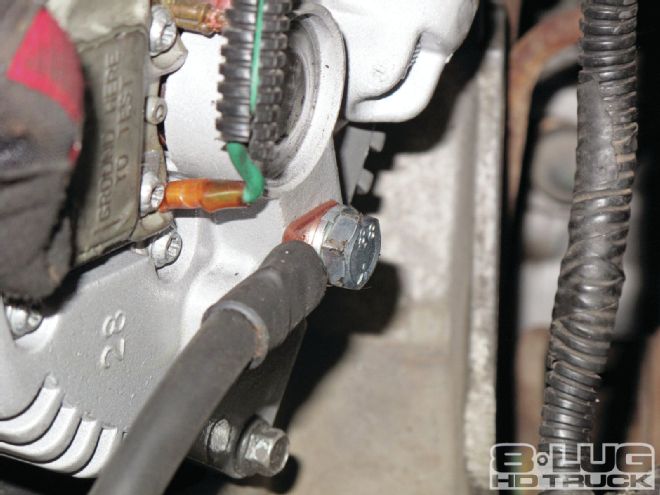

| Flexible Quick Cable welding wire and solid copper lugs were used for grounds from the back of the alternator cases to the block.

Back at Ken Imler’s facilities, the new (actually better than new) alternators were reinstalled. Following Sammy’s advice, Rick used flexible Quick Cable welding wire and solid copper lugs for grounds from the back of the alternator cases to the block.

Of course, something has to spin the alternators. A new Gates Green Stripe FleetRunner Micro-V belt is expected to last at least 100,000 miles under severe conditions. A new Gates belt tensioner and Gates idler pulleys replaced factory units.

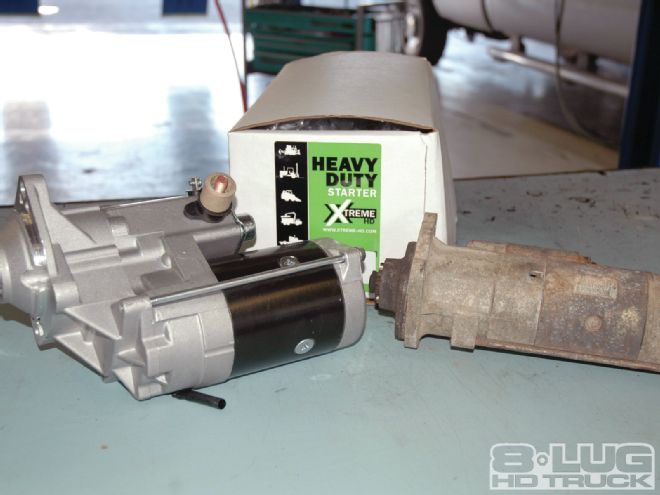

Returning to where we began, nothing works until the engine starts. Motorcar Parts of America replaced the rather puny factory Mitsubishi starter with an Xtreme X17802N 4.0KW featuring an offset gear reduction design. Installation was straightforward for the experienced technicians at Ken Imler’s Diesel Performance. The mating face on the bellhousing was buffed clean, and a small, unneeded tab on the OEM power cable was removed. Permatex maximum strength thread locker was used on all bolts and studs.

MPA Xtreme starters feature precisely machined components for consistent performance, oil-impregnated bushings for maximum durability, and specially coated wiring for additional protection from heat. Synthetic lubricants reduce cranking resistance and improve durability.

Completed units are individually end-of-line tested on proprietary load-based testers across a full range of operating requirements using computerized equipment that simulates actual vehicle use. Starter testing includes rpm and motor amperage at load conditions, solenoid hold-in and pull-in coil amperage, and solenoid interrupt.

The shear size of the Xtreme starter’s offset gear reduction design is impressive, but the real test came when we turned the key. Amazing, in a word. The powerful starter spun the engine like a top! The Xtreme X17802N was designed specifically for the Ford 7.3L Power Stroke engine. Motorcar Parts of America makes starters and alternators for most vehicles sold in the U.S. Not all trucks require the Xtreme model.

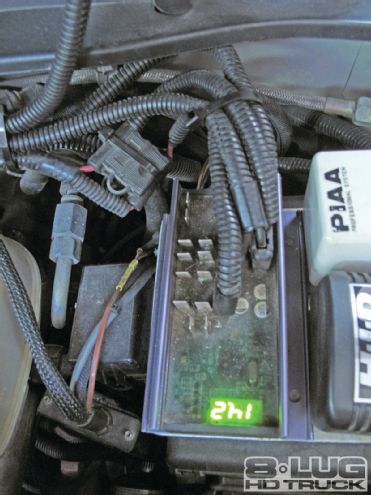

Finally, given the number of computers and other hidden electrical draws on modern trucks and RVs, whenever we need to leave our vehicle for more than a couple of weeks, we hook up a VDC BatteryMINDer (Model 2012-AGM). BatteryMINDers are the new generation of SMART pulse-type computer-on-a-chip chargers that safely charge and maintain all size, type, and brands of batteries including starter, deep-cycle, and sealed. They do all this without ever overcharging—no matter how long they are left on: days, weeks, months, or even years. The Model 2012-AGM is precision-set for all sizes and brands of 12-volt AGM lead-acid batteries, including but not limited to AGM batteries by: Optima, Odyssey, Lifeline, Deka, MK, Universal Power, and Trojan. The model 2012 is for flooded and gel batteries.

As we follow the Silk Road through the Wakhan corridor, we will climb over the icy tracks of the famous Wakhjir Pass (16,151 feet) in the Pamir Mountains. Since Victorian times, the Pamirs have been known as the Roof of the World. The Wakhan Corridor is a historic route between Afghanistan and the Tashkurgan Tajik Autonomous County in Xinjiang, China. It’s no place you want to hear the ominous “click, click, click” when you turn the key in the morning. Even just at your favorite campground by the lake is not a good place, either.