Modern diesel performance is advancing at a radical pace. Current pickup truck engines can make nearly 1,800 lb-ft at the wheels yet still be driveable on the street. Getting that much power to the ground, however, is another matter altogether, and virtually every single part in a transmission can be a weak link.

| 1103dp The Strongest Dodge Transmission Ever Built lowering Transmission

Through the years, Sun Coast Converters has made a business of fixing these weak links for diesel owners one at a time. In fact, it has fixed so many Dodge 47RH, 47RE, and 48RE transmission failures that it has done the unthinkable-it can now replace virtually every piece in Dodge's four-speed automatic transmission with an upgraded part.

The OM3GA

Sun Coast calls this transmission package the OM3GA. It's a Dodge 47RE/48RE-based four-speed automatic designed to handle obscene amounts of horsepower and torque. It can be tailored to a variety of applications, including Ford, Dodge, and Chevy diesel trucks. This transmission was developed through the years as Cummins racers and hot-street-truck owners advanced their engines' horsepower levels.

| 1103dp The Strongest Dodge Transmission Ever Built assembled Transmission

Strength Training

In the beginning, Cummins-powered Dodge trucks wiped out torque converters. Then the weak link moved to the input shafts. That led shops like Sun Coast to develop better converters and input shafts machined from billets of high-strength steel. These "billet shafts," as they are often called, still weren't always strong enough. The Sun Coast OM3GA fixed this problem with the introduction of a larger-diameter input shaft.

| Here's an OM3GA transmission installed in the J&H Perfomance Ramcharger. Notice the short ouput shaft (A), Mag-Hytec pan for additional cooling (B), universal TH350 crossmember for engine swaps (C), and the flexplate speed sensor that sends out a V-8 tachometer signal to run a variety of electronics (D).

Increasing the diameter of the input shaft meant custom pump gears had to be made, along with a custom stator support, stator, and torque converter. The intermediate and output shafts have also been upgraded with billet shafts machined from 300M alloy.

Those of you with two-wheel-drive competition trucks will now have the option of running a billet output shaft. In the past, two-wheel-drive output shafts tended to snap in high-horsepower applications, so a special tailshaft adapter was made to permit the use of a four-wheel-drive 300M output shaft for two-wheel-drive applications.

Power Application

Unfortunately for mega-horsepower diesel owners, the carnage didn't end there. Bands would be destroyed, clutches would slip, and drums would explode, so the OM3GA transmission uses a revised clutch count and a rigid Second gear band (with more apply area), as well as a billet drum and steel planetary gears. The transmission has an increased-pressure Second gear servo, which meant the strut, anchor, and apply levers all had to be custom-made by Sun Coast.

| On vehicles such as Darren Morrison's 7-second diesel drag truck, the Dodge output shaft (bottom) can snap off during hard launches. To fix this problem, Sun Coast developed this four-wheel-drive shaft and adapter combination (top) that allows two-wheel-drive trucks to finally use a billet output shaft.

Controls

The strongest Dodge transmission in the world won't do any good without a way to shift it, so Sun Coast came up with a custom valvebody that allows for a variety of control strategies. The valvebody has rerouted oil circuits for quicker and firmer shifting and can be controlled with an electronic PCS transmission controller, or it can be shifted manually. The OM3GA can also be ordered with a reverse-shift pattern that changes the gear-selection pattern from the traditional: Park, Reverse, Neutral, Drive, Second, and First to: Park, Reverse, Neutral, First, Second, and Drive. In both cases, Overdrive is activated electronically.

Catapult Launches

The OM3GA can even be ordered with an optional transbrake. A transbrake is a traditional piece of drag-racing equipment that basically amounts to a driveline catapult. The transbrake works by putting the transmission in both First and Reverse to effectively lock the truck in place. This allows the driver to load the engine without the use of the brakes. This can be helpful in both sled pulling and drag racing applications in which drivers are trying to spool larger turbochargers.

| The OM3GA transmission can be ordered with either a manual valvebody or a trick, PCS-controlled unit, which allows stock-like shifting strategies to be employed, even on newer, common-rail Dodges.

Custom-Tuned Torque Converter

The lock-up torque converter can be ordered in a variety of custom stall speeds, from 1,900 rpm to 3,200 rpm, to allow the transmission to match the turbocharger selection. The custom valvebody will also allow the converter to be locked in any gear (the OEM strategy only allows the converter to lock in Third and Overdrive) so that a higher-stall converter can be used for easier spooling and to reduce smoke on the street.

Duramaxes And Power Strokes, Too!

The OM3GA isn't just for Cummins-powered Dodge trucks. When used in a Duramax-powered truck, the OM3GA uses a custom converter with a Dodge back half and a front that will match up with the Duramax flexplate. Custom adapters are used to mate it to the GM transfer case, and both stock driveshafts can be retained. Currently, the world's quickest and fastest fullsize Duramax uses this transmission and has run a best eighth-mile time of 5.87 seconds at 123.5 mph-which translates into nearly 1,400 hp at the wheels. Ford applications are currently under development and should be available by the time you read this.

| 1103dp The Strongest Dodge Transmission Ever Built chevy Silverado 2500 Side

How Much Does It Cost?

With all the custom parts, the OM3GA's price is based on a sliding scale. Sun Coast's price for the OM3GA transmission starts at $8,000. While that's a lot of money, consider that if a truck breaks an input shaft, the repair bill can be around $2,500, because the vehicle will need a new torque converter, hub, front pump, and the labor to install everything. While Grandpa Bob probably doesn't need this transmission to tow his pop-up camper, if you're planning to race a truck that makes more than 700 hp at the wheels, we'd strongly recommend the OM3GA.

| When any type of internal transmission shaft breaks (especially inputs), a variety of parts, pieces, and metal can be sent throughout the transmission, often necessitating a full rebuild. In high-horsepower applications, the OM3GA's massive shafts will prevent this type of breakage-and a costly future repair bill.

Real-World Testing

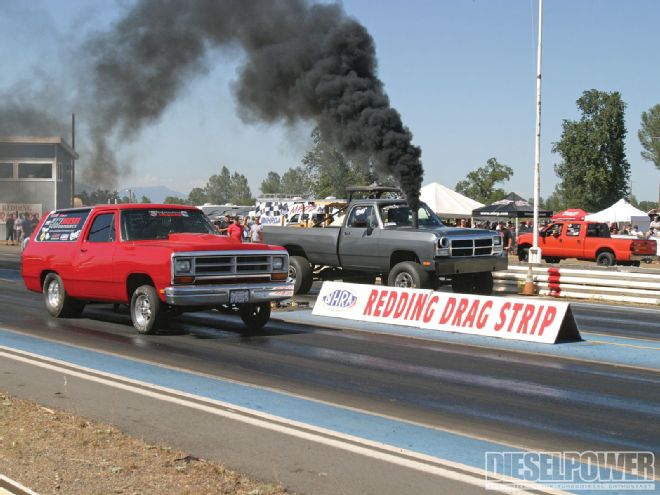

In theory, the wild OM3GA transmission should be capable of handling almost any power level, and Sun Coast Converters reports that the OM3GA has been tested in applications up to 1,700 hp. We wanted to see for ourselves how it would hold up, so we followed along as it was installed and tested it in Harvey Grant's Cummins-powered race truck.

The transmission was tested throughout a racing season that included a dozen 10-second passes-all launching off the transbrake. The converter was also locked in First gear and kept locked for the First to Second shifts-which are extremely hard on the transmission's shafts.

The OM3GA held strong, and the fluid still looked fresh after the season of racing, which included a best pass of 10.1 seconds at 135 mph, with a 60-foot time of 1.55 seconds and an eighth-mile time of 6.55 seconds. We also rode in the OM3GA-equipped Dodge and can report that shifts were surprisingly smooth yet functionally firm. The manual-shift valvebody and 2,500-rpm stall converter made our particular test unit more suitable for the track than the street. Although this transmission was bred for competition use, many of its parts could also be used in a transmission you drive with every day.

Heavy-Duty Transmission Parts-Explained

Diesel performance has driven the need for stronger parts than the transmission industry has ever developed. The low-end torque and weight of our diesel trucks gives drivetrain parts a beating. This torque challenge has driven a number of new transmission technologies-many of which we talk about every month in the pages of Diesel Power. For those of you looking for a cheat sheet, here are some of the common transmission terms explained.

| The stock Dodge 48RE input shaft measures 0.962 inch in diameter at the most common fracture point. When laid next to Sun Coast's 1.270-inch-diameter OM3GA input shaft, the strength increase is clear. The OM3GA input shaft is 32-percent larger than the stock piece, and the same size as an Allison 1000's input shaft, while being made out of a stronger material.

300M: A high-strength, low-alloy version of 4340 steel that is often used in applications such as transmission shafts to prevent twisting or breakage.

4340: A high-strength, low-alloy steel that is often used in applications such as transmission shafts to prevent twisting or breakage. Second only in strength to 300M steel.

47RH: A hydraulically controlled four-speed automatic transmission found in '94 to '95 Dodge trucks.

47RE: An electronically controlled four-speed automatic transmission found in '96 to '02 Dodge trucks, as well as some '03 models.

48RE: An electronically controlled four-speed automatic transmission found in '03 to'07 Dodges.

Billet: Contrary to popular belief, billet is not a type of metal. It's merely a word that means a block of raw material a part can be machined from. When people use the term "billet," they mean a part has been machined into shape, as opposed to being cast or forged.

Clutch: A flat, circular disc in the transmission that is coated with a friction material and is used to transmit torque when various gears are applied.

Steels: Flat, circular discs made of steel that the clutch discs clamp against to transmit torque.

Input shaft: The leading or front shaft of the transmission, which is splined to engage the torque converter with the input drum.

Intermediate shaft: The second shaft (front to back) inside the transmission. The intermediate shaft typically supports all the planetary gears in a transmission.

Lock-up torque converter: A fluid-coupling device that's used to connect the engine to the transmission. In diesel applications, clutches are used to turn the torque converter into one solid piece, eliminating any slippage that may occur.

Output shaft: The third or final shaft (front to back) in the transmission. The output shaft sends torque into the transfer case or to the rear driveshaft.

Planetary gears: A series of planet gears inside a revolving ring gear.

Transbrake: A valvebody that has modified circuits to enable First and Reverse gears to engage at the same time, effectively locking the transmission while still applying torque to First gear. When the transbrake is released, Reverse is disengaged and only forward power application remains.

Valvebody: The ATF circuits that control which gear is engaged, and when. The valvebody is the brain of the transmission.