Areas of your engine that endure high amounts of stress and vibration, like the transmission, but that have little means available for you to lock the bolts into place, are places where you want to use safety wire. Safety wire can create the tension needed to lock a bolt in place and prevent it from working free. Learning how to use safety wire pliers will make attaching the wire a fast and easy process. Specifically designed for this use, safety wire pliers are easy to use once you know what to do.

Using the cutting edge of the safety pliers, cut a length of safety wire that will be long enough to loop around both bolt heads and slightly overlap. The cutting edge of the pliers is located directly behind the flat grips of the head. It is a slightly depressed flat area that when you place the wire between the edge and press the handles closed will cut the wire.

Wrap the safety wire around the bolts so the two ends of the wire meet in the middle. The best way to picture this is to imagine the bolts as pulleys and the wire as the "belt" you are wrapping around them. You want the wire to form a loop or band connecting the two heads.

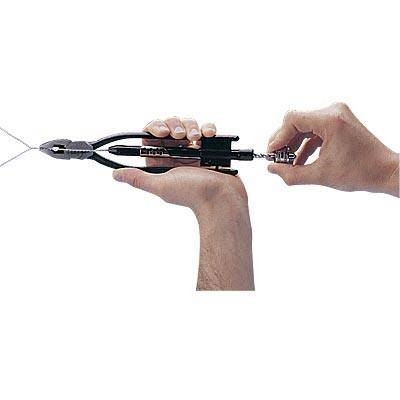

Open the handles of your safety wire pliers slightly and place both ends of the wire between the grips of the head and press the handles closed. Lock the handles by pressing once firmly again, you will feel and hear the handles locking.

Hold the pliers steady and pull up on the center knob, this will activate the spring loaded coil and spin the wires together.

Push the knob back in to release the tension and pull it back out again to add another twist. Repeat this until the wire is twisted completely. Press the handles pliers again to release the safety wire.