Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Whether building a buggy, bumper, or rollbar, you need to find something to build it out of, and although plasticor wood may be cheap and lightweight, I felt that my buggy would last a bit longer if I made it of steel tubing. But this brought me to the question of what tube to get and how much I needed. I discussed the options with quite a few different chassis fabricators and determined that roughly 300 feet of drawn-over-mandrel (DOM) mild steel would be more than enough for a two- or three-seat buggy with about a 106-inch wheelbase. In addition, I started researching different types of tubing and even did some home-brew destructive testing of what's available for fabricators.

Many steel materials must be certified by the American Society for Testing and Materials (ASTM) and they have a large set of manuals that have chemical, strength, and hardness requirements of different alloys and manufactured types of steel. While digging through these encyclopedias I found that HREW (hot rolled electrically welded) has a yield strength of 30,000 to 45,000 psi and an ultimate strength of 42,000 to 62,000 psi depending on its carbon levels. What "yield" means is that the tubing will deform without returning it's original shape, where "ultimate strength" is when the tubing will actually fail and tear. DOM ratings range from 60,000 to 70,000 yield and 70,000 to 80,000 ultimate strength, though when I looked at the actually mill test report of the tubing, it had numbers about 5,000 psi above these required minimums. Chromoly has numbers in the 80,000 to 85,000 psi range for yield depending on whether the tubing is stress relieved (slightly lower numbers) and 90,000 to 95,000 ultimate strength, but again actual mill test results for chromoly from Industrial Metal Supply had yield at around 110,000 and ultimate strength at over 120,000. So what do all these numbers mean? I'll show you.

Since the swinging hammer wasn't getting the results anywhere near what I've seen rocks give buggies and rollbars, I decided to take it to the next level and lay the royal beat down on each tube with a ball-peen hammer. After five swift blows to each tube I was really noticing some carnage. From left to right, the aluminum was sad (probably why there aren't many aluminum buggies, bumpers, or rollbars running around) and the HREW wasn't holding up much better. The DOM was only slightly oval, but still better than the thin-wall chromoly. The chromoly was holding up very well, but for $6 to $8 per foot, it had better.

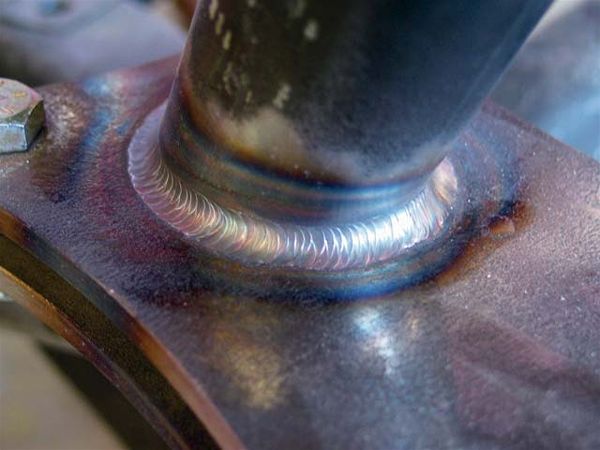

So why did I not use 4130 chromoly tubing? I seriously considered it, but price, welding technique, and application all deterred me. Chromoly is usually about a dollar or two more expensive than DOM per foot and isn't as commonly available. Though many fab shops MIG-weld chromoly with absolutely no problems, my research found that TIG-welding and proper stress relieving is the best way to assemble a chromoly chassis, and that was more than I was ready to take on-not to mention very time consuming. Most of us have access to a MIG-welder rather than a TIG machine. If you do decide to MIG-weld chromoly, you should use at least ER70S-or better yet-ER80S wire, and consider having the chassis stress relieved from an experienced heat treater such as Certified Steel Treatment, since MIG-welding heats the metal much faster and is more violent to the base material, thus causing more internal stress. In fact, NASCAR requires DOM mild steel in all competitors' vehicles to help keep costs down and to have better crumple characteristics and absorption of deadly forces in high-speed crashes.

There are people who will flat-out tell you that pipe is not the right material for your 4x4, but that is not 100-percent true. It is more important to use it in the correct way, and understand what it is. In my discussions with a representative of the North American Steel Alliance, I was told that pipe is very similar to HREW mild steel tubing. However, pipe is produced for moving liquids and gases, not structural applications, and tubing is held to much tighter chemistry control than pipe. Plus, pipe is measured by the inner diameter (ID) where tubing is measured by the outer diameter (OD). What this means is that there are special dies needed in order to bend pipe, and these dies often come in larger radius curves.

So is pipe OK for building with? If you are building a bumper or rock sliders it is just fine. Just get some schedule 40 ASTM in 1 1/4-, 1 1/2-, or 2-inch sizes. As for building a cage with it, we discussed that with Bill Rowlette from Welder Bill't, as he actually has a buggy built of pipe. His reasoning was that pipe is cheaper than a similar walled tubing and can withstand a fair bit of abuse. Since schedule 40 pipe comes in 0.132 to 0.140 wall (where tubing usually jumps from 0.120 to 0.188 wall), the pipe is definitely heavier than 0.120 HREW. However, pipe is generally more brittle and will break before it deforms, so we can't recommended it for any safety cage whatsoever. However, as with any cage or buggy, it is more important to have a quality designed structure (especially if you are using lesser material) than exotic materials with a lousy design.