Ali Mansour

Brand Manager, 4WD & Sport Utility

Ali Mansour

Brand Manager, 4WD & Sport Utility

As you’ve read with our Four Wheeler and Pickup Truck of the Year competitions, modern 4x4s are downright impressive right out of the box. While comfort and fuel economy seem to be the focus these days, some OEMs (original equipment manufacturers) are installing key features intended to attract off-road enthusiasts. Items such as mud-terrain tires, off-road-oriented suspensions, and our personal favorite, selectable differential lockers. Jeep, Ram, Ford, Toyota, and Land Rover all have new 4x4s that offer at least one (typically rear) selectable locking differential.

What do all of these traction aids have in common? They are all electronically actuated. That’s right. No air, no cables, no special levers—just a simple press of a button and the locker is engaged. And since selectable lockers offer the best balance of on-road invisibility and off-road performance, it’s a no-brainer why they are the only locker option offered in a factory 4x4. Like many of you, we spend thousands of miles of on-road time behind the wheel of our 4x4. Living in the Southeast, we also get a broad range of winter conditions, which often benefit from having an open differential over an automatic locker. Needing some traction aids for our ’04 Jeep Wrangler Unlimited, we took a play from the OEM playbook and decided to go with an electronically actuated locker set from Eaton.

Our ’04 Wrangler Unlimited is equipped with a Dana 30 front and Dana 44 rear. Eaton’s ELocker for the Dana 44 differential is designed to fit 30-spline Dana 44 axles from 1970 to 2015. The dual-bolt pattern on the carrier even allows it to be used with the larger, next-generation Dana 44 gears found in the ’07-present Jeep Wrangler JK. Fit with forged internal gears and a beefy four-pinion case, it’s the strongest Dana 44 ELocker Eaton has ever produced.

Our ’04 Wrangler Unlimited is equipped with a Dana 30 front and Dana 44 rear. Eaton’s ELocker for the Dana 44 differential is designed to fit 30-spline Dana 44 axles from 1970 to 2015. The dual-bolt pattern on the carrier even allows it to be used with the larger, next-generation Dana 44 gears found in the ’07-present Jeep Wrangler JK. Fit with forged internal gears and a beefy four-pinion case, it’s the strongest Dana 44 ELocker Eaton has ever produced.

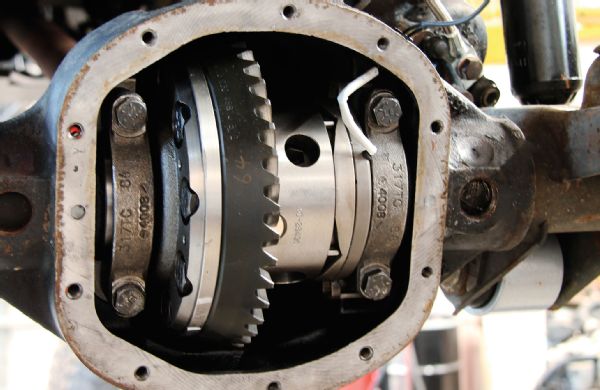

Eaton is best known for its legendary no-nonsense Detroit Locker, but the company also has a substantial foothold in the selectable locker market with its ELocker. The ELocker has been in the Eaton stable for a few years, but the company continues to fine-tune the product. These improvements have included precision-forged gears for increased strength, a new wiring harness for easier instillation, and a heavy-duty four-pinion case on its Dana 44 application. The ELocker functions as a completely open differential when not engaged and converts to an ultra-strong spool-type locker with a simple flip of a switch.

Since installing a selectable locker set isn’t something we do on a regular basis, we enlisted the help of the off-road gurus at Low Range 4x4 in Wilmington, North Carolina. The actual act of installing the lockers is very straightforward, but getting the correct gear pattern takes proper tooling and knowhow. Thankfully, Low Range had us on the lift in the morning and in the dirt that evening. So far, we have relatively low miles on the locker set but no complaints.

Engagement is practically instant and release is nearly just as quick. There isn’t a series of computers to communicate with as is the case with the Jeep Wrangler Rubicon JK, so they are a bit more user-friendly in comparison to some of the electronically actuated OEM lockers we’ve tested in the past. Our 35-inch mud-terrain tires are sure to put the lockers to the test, but for now, we are pleased with the performance upgrade.

The Dana 30 ELocker takes a unique set of carrier bearings. Fortunately, Eaton provides the part numbers needed, which we were able to pick up at our local parts store. Since our Jeep was already equipped with 4.88 gears, we just needed to remove the old ring gear and place it on the new carrier. To do so, you’ll need to remove the snap ring that holds the engagement ring in place.

The ELocker works by using an electromagnetic stator assembly to engage a ramping ring. When 12V power is sent to the ring, it engages the three locking pins, which actuate an internal side gear inside the case. This causes the differential to lock both wheels in at the same speed. When disengaged, the side gear retracts, allowing the differential to go back to working as a standard open differential.

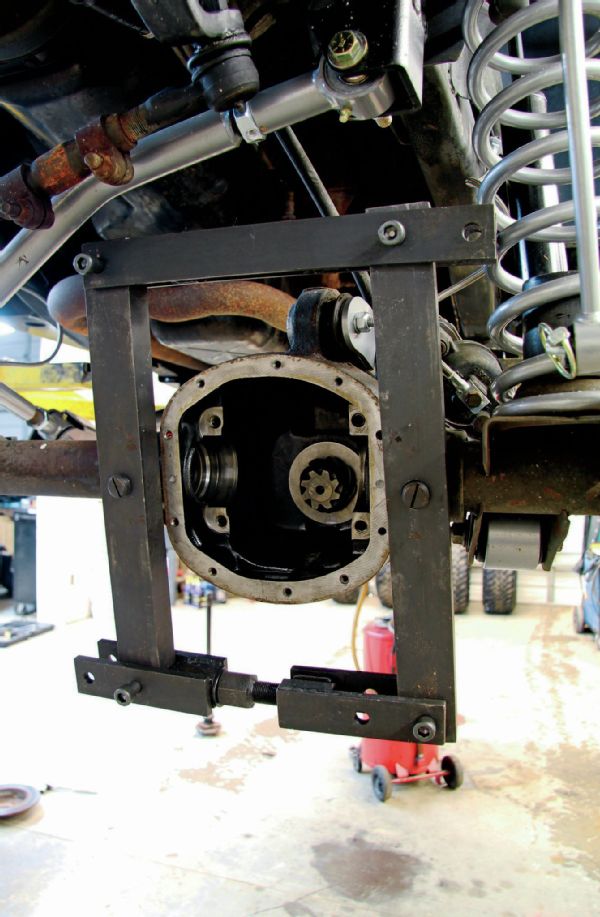

One tool that is often overlooked, but an absolutely great asset to have when setting up differentials, is a case spreader. Case spreaders allow you to remove some of the housing pressure from the differential, which makes installing and setting up the differential a more precise process. Our Dana 30 front (shown here) is designed to take internal shims, meaning the shims sit between the bearing and differential, as opposed to the outside of the bearing.

To route the ELocker wires outside of the differential, you’ll need to drill a 1⁄2-inch hole in the top of the differential housing. Thankfully, the cast metal is relatively easy to drill through. To seal the opening, a rubber grommet is included. We used a bit of RTV silicone around the opening before sliding the grommet through.

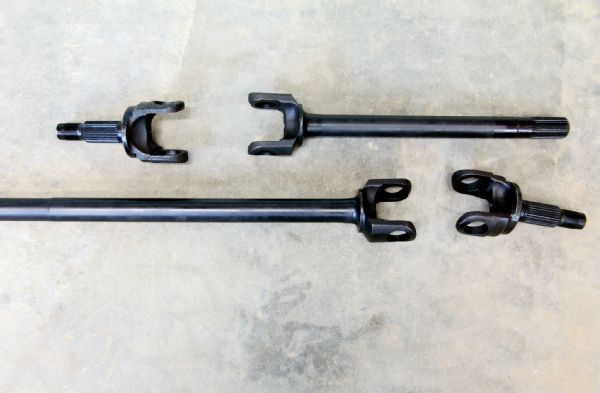

With meaty 35-inch tires, we are right at the limit of strength with our low-pinion Dana 30 front axle. To give the axle a better chance of surviving off-road, we installed a set of Alloy USA inner and outer axleshafts. The 4340 chromoly ’shafts are heat-treated, tempered, and induction hardened, which is said to make them 40 percent stronger than the stock ’shafts. Each ’shaft also has a 10-year warranty and comes with a black anodized finish.

To finish out our front axle upgrade, we hammered in a set of Alloy’s new X-joints. The cold-forged steel composition U-joint is made of chromium, molybdenum and nickel alloy, and is fit with a hardened case. Helping the joint live longer is an easy-to-access grease fitting.

Eaton’s ELocker doesn’t require any special fluid, but we opted to fill up each diff with 75W-90 Royal Purple synthetic oil. Going with the synthetic should help keep our diff cooler on those longer highway outings, as well as extended time between oil changes.

PhotosView SlideshowThe final portion of the install process is to wire up the lockers. Included with each ELocker is a dedicated switch, wire loom, relay, and a wiring bundle that is color-marked and clearly labeled. We used the blank spot next to our accessory ports at the bottom of our Jeep’s center stack to mount the switches. We grabbed our 12V power source via the stock fuse box under the hood.