Ken Brubaker

Senior Editor, Four Wheeler

Ken Brubaker

Senior Editor, Four Wheeler

The differentials in your rig take the torque from the engine, carried by the driveshafts, turn it 90 degrees and send it to the tires. In addition to this task, the differentials also "gear down" the power. This gearing is called the "axle gear ratio." If your rig has 3.43:1 gearing, this means that the pinion gear will turn 3.43 times for each turn of the ring gear. "Tall" gears are actually numerically low (like 3:07:1) and allow for high road speeds, while "short" gears are numerically high (like 4.56:1) and are good for low speeds, towing, or quick acceleration.

With the addition of larger 35-inch-diameter tires, this Unlimited needed shorter gearing to compensate. And while we were at it, we installed an Auburn Gear ECTED Max locker to make it more capable on the trail.

With the addition of larger 35-inch-diameter tires, this Unlimited needed shorter gearing to compensate. And while we were at it, we installed an Auburn Gear ECTED Max locker to make it more capable on the trail.

Manufacturers determine differential ratios by factoring in the tire diameter and planned use of the vehicle, among other things. Swapping larger-diameter tires onto a rig results in the need to install gears with a shorter ratio. What if you don't? Well, depending on the increase of the tire diameter, you could encounter sluggish acceleration, inaccuracy of the speedometer and odometer, more stress on the transmission and driveline, and a substantial fuel mileage decrease. How do you know what differential ratio to use? Well, a good starting point is to use shorter gears with a ratio percentage equal to the percentage increase in tire size. In other words, if you increase tire size by 15 percent, install 15 percent shorter (numerically higher) gears.

Recently we watched as Moab Offroad, a six-bay shop in Louisville, Kentucky, with over a decade of experience in the off-road business, regeared a '10 Jeep Wrangler Unlimited using Superior Axle & Gear components. Superior's history dates back to 1934, and today they offer a mind-boggling array of parts for just about every axle. This Unlimited had been fitted with 35-inch-diameter tires, which were four inches larger than the stock 31-inch diameter tires. This was a 13-percent increase. From the factory, this rig came with 4.10:1 gears, and the owner was installing 4.88:1 gears. A set of 4.56:1 gears would've been an 11-percent increase, but he went with the 4.88:1 gears, which had a 19-percent increase, because of the anemic V-6 engine and the added weight of the tires and other bolt-ons.

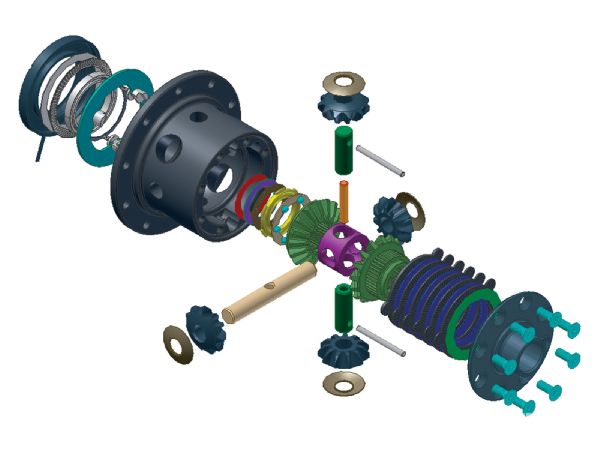

Also on the agenda was the installation of an Auburn Gear ECTED Max locker in the rear axle. Auburn Gear is located in Auburn, Indiana, and they have over 60 years of gear manufacturing experience at that location. The ECTED Max is a cool locker that acts as a limited-slip when unlocked, and you can read more about the ECTED Max in the accompanying sidebar.

Whether you want to attempt a gear change yourself, or if you just want to understand the basic mechanics of a swap, here's a general overview of how the swap went on this Dana 44-equipped Unlimited.

Can You Swap Gears Yourself?

Most folks choose to leave gear swaps to the professionals. One of the reasons is that most wheelers don't have vehicle lifts that allow easy, stand-up access to the axlehousings, so the majority of the work would have to be completed while laying flat on your back. If you think you're up to the task, make sure you have all the recommended tools and be prepared for surprises. The most important part of a gear swap is getting the proper ring and pinion backlash and differential carrier bearing preload. If these aren't set properly, the differential will not last very long.

About the ECTED Max

One of the cool things about the ECTED Max is that it acts as a limited-slip differential when disengaged and as a full locker when engaged using the dash-mounted switch. It's built tough, and the gearing is made from aircraft-quality, 9310 heat-treated billet steel. It's quiet, can be switched on or off on-the-fly, and has no shift forks or pins that must be lined up for locker mode. It is available for a variety of axles and can even be used in front axles. By the time you read this, the new Super 44 ECTED Max should be available, and it works with 35-spline axleshafts.

Bottom Line

This install took place with only 1,800 miles on the Unlimited's odometer, so corroded bolts weren't a problem. Nor were there any problems with abnormal wear in the axle assemblies. The owner of this rig reports that since the install, he has piled over 15,000 miles on the Unlimited with no problems to report. He says the 4.88:1s work well with the available engine power and the 35s. As a bonus, the shorter diff gears improved the Unlimited's crawl ratio from 31:1 to 38:1. The owner also likes the fact that the ECTED Max acts as a limited-slip differential when unlocked. He says that when he needs the traction of the locker it has activated quickly and quietly with just the flick of the switch.