The Jeep Dana 30 axle, found in the front of all base-model jks, is no trail champion. The term "bare minimum" comes to mind whenever somebody inquires about the unit's ability to handle the trail. That is why Jeep's JK Rubicon model comes with the stronger Dana 44 up front. However, even the Rubicon 44 has some weak links in stock form. Yet that does not mean you should forgo the next weekend-wheeling adventure on your calendar. Smart driving techniques and a few simple upgrades can get you and your Dana 30/44 through even the toughest of trails. We know what you're thinking: Why waste money on a strengthening a Dana 30 or 44 when you can save up for something a lot stronger? The answer lies in return on investment. Sure, 1-ton axles may be on your wish list, but you can still invest wisely in the stock pieces to buy yourself time and/or ensure that your JK can handle a 35-inch-tall tire on the trail. (Those heavier 1-ton axles will cost you extra at the gas pump, too.)

Here, the author pilots his '07 Jeep Wrangler X through the Rubicon Trail during last summer's Jeepers Jamboree to demonstrate the effectiveness of the upgrades shown in this story. Running 37-inch BFG Mud-Terrain tires, the trail-prepped Dana 30 was able to survive even the roughest terrain encountered during the three-day trek.

Here, the author pilots his '07 Jeep Wrangler X through the Rubicon Trail during last summer's Jeepers Jamboree to demonstrate the effectiveness of the upgrades shown in this story. Running 37-inch BFG Mud-Terrain tires, the trail-prepped Dana 30 was able to survive even the roughest terrain encountered during the three-day trek.

With this story, we will illustrate exactly what is needed to reinforce each of the critical areas of the Dana 30 front axle. We will also show you how to improve the resale value of your stock parts so, should you decide to upgrade to 1-ton axles later you can sell off the stock parts for more than you might have thought. That way, you can feel confident with your purchases.

What About Resale Value?

Keeping in mind that the used JK front axle market was alive and well when this article was published, we think you can expect to get anywhere from $700 to $1,400 for a fully built JK Dana 30 in decent shape. This price is assuming that the axle has upgrades of equal value to the ones showcased in this story. However, keep in mind that prices depend on the condition of said parts and what the buyer is actually willing to pay for them. The idea here is to stress the fact that just because you do not have $10,000 to plunk down on a pair of built 1-ton axles, it doesn't mean you should refrain from building your Jeep for moderate trail use. By performing upgrades a little at a time, you can still go out and enjoy the activity while saving up for the big winter swap project. We think money is well spent when it enables you to get out and enjoy our wild places-even if the precise place you want to go requires a short hike.

The first upgrade all JK owners should consider is strengthening the front axlehousing. Jeep's attempt to cut weight out of the front axle assembly leaves the units extremely vulnerable to deflection-especially when larger tires are involved. Poly Performance offers a Dana 30 axle reinforcement kit, which addresses this issue and adds strength in key areas where the unit is known to fail. The kit consists of two essential parts: the axletube sleeves and the inner "C" gussets. Made from 2-inch-thick, 0.250-inch-wall 1026 DOM tubing, the sleeves are machined with an outer diameter that fits tightly into the stock axletubes. Once installed, any combination of front axleshafts will still fit into the housing. This system increases the Dana 30/44 axletube strength by 59 percent over stock. Note that this upgrade requires that you drill and plug-weld your stock axletubes.

The first upgrade all JK owners should consider is strengthening the front axlehousing. Jeep's attempt to cut weight out of the front axle assembly leaves the units extremely vulnerable to deflection-especially when larger tires are involved. Poly Performance offers a Dana 30 axle reinforcement kit, which addresses this issue and adds strength in key areas where the unit is known to fail. The kit consists of two essential parts: the axletube sleeves and the inner "C" gussets. Made from 2-inch-thick, 0.250-inch-wall 1026 DOM tubing, the sleeves are machined with an outer diameter that fits tightly into the stock axletubes. Once installed, any combination of front axleshafts will still fit into the housing. This system increases the Dana 30/44 axletube strength by 59 percent over stock. Note that this upgrade requires that you drill and plug-weld your stock axletubes.

The inner "C" gussets of the Dana 30 and even the Dana 44 are also prone to bending when used with oversized tires. Here you can see how the Poly Performance gussets reinforce the upper and lower sections of the stock forging to boost the unit's strength. The idea here is to spread out the load path across a larger section of the axletubes.

The inner "C" gussets of the Dana 30 and even the Dana 44 are also prone to bending when used with oversized tires. Here you can see how the Poly Performance gussets reinforce the upper and lower sections of the stock forging to boost the unit's strength. The idea here is to spread out the load path across a larger section of the axletubes.

With the housing strengthened, the next logical place to put your money is in axle gearing. Upgraded gearing resolves the most common issue associated with the factory Dana 30/44-running larger tires. With the stock 3.55:1 gearing, the model X JK is limited to a 33-inch-tall tire; any bigger and the vehicle becomes super-sluggish off the line and is basically undrivable around town. We opted for a set of 4.88:1 gears from Superior Axle & Gear because we planned to run 37-inch rubber on this rig. Superior's ring and pinion sets are manufactured from premium 8620 steel material with precise tolerances to improve gear contact and set-up. Heat treatment ensures that Superior's gearsets last the life of the vehicle while balancing the need for shock load deflection. We like the fact that they come with a two-year warranty against manufacturing defects.

With the housing strengthened, the next logical place to put your money is in axle gearing. Upgraded gearing resolves the most common issue associated with the factory Dana 30/44-running larger tires. With the stock 3.55:1 gearing, the model X JK is limited to a 33-inch-tall tire; any bigger and the vehicle becomes super-sluggish off the line and is basically undrivable around town. We opted for a set of 4.88:1 gears from Superior Axle & Gear because we planned to run 37-inch rubber on this rig. Superior's ring and pinion sets are manufactured from premium 8620 steel material with precise tolerances to improve gear contact and set-up. Heat treatment ensures that Superior's gearsets last the life of the vehicle while balancing the need for shock load deflection. We like the fact that they come with a two-year warranty against manufacturing defects.

This photo shows the difference in size of the JK rear Dana 44 pinion gear and the front JK Dana 30 pinion gear. Obviously, the Dana 44 unit is much stronger, thanks to its larger size. But did you know that you can improve the strength of a ring and pinion gearset by simply having it cryogenically treated? Cryogenics bathes the metal in liquid nitrogen at minus-301 degrees Fahrenheit. The process changes the state of the metal, making it much less likely to develop fractures or cracks. The results are, in the simplest of terms, stronger, more durable metal with a much higher yield strength. We sent our Dana 30 gears out to Cryo Science of Oceanside, California, to have this treatment applied. When the Dana 30 gearset was returned to us, the strength was nearly the same as that of the Dana 44 unit in the picture. The cost of this process was a little over $50 plus shipping and handling.

This photo shows the difference in size of the JK rear Dana 44 pinion gear and the front JK Dana 30 pinion gear. Obviously, the Dana 44 unit is much stronger, thanks to its larger size. But did you know that you can improve the strength of a ring and pinion gearset by simply having it cryogenically treated? Cryogenics bathes the metal in liquid nitrogen at minus-301 degrees Fahrenheit. The process changes the state of the metal, making it much less likely to develop fractures or cracks. The results are, in the simplest of terms, stronger, more durable metal with a much higher yield strength. We sent our Dana 30 gears out to Cryo Science of Oceanside, California, to have this treatment applied. When the Dana 30 gearset was returned to us, the strength was nearly the same as that of the Dana 44 unit in the picture. The cost of this process was a little over $50 plus shipping and handling.

Whenever you re-gear a vehicle, it's a good idea to use a new master installation kit like the Superior kit shown here. This will ensure that all the necessary shims, bearings and races are available to set up the carrier the correct way for dependable service.

Whenever you re-gear a vehicle, it's a good idea to use a new master installation kit like the Superior kit shown here. This will ensure that all the necessary shims, bearings and races are available to set up the carrier the correct way for dependable service.

For improved traction, we selected the Auburn ECTED Max differential for this build. We like this differential because it is the only aftermarket differential available that offers both 100-percent lock-up at the push of a button and the characteristics of a limited slip when disengaged. It can be actuated on the fly at any speed, and it does not rely on shift forks or cables to operate. The unit uses 12-volt DC current and is virtually noise-free.

For improved traction, we selected the Auburn ECTED Max differential for this build. We like this differential because it is the only aftermarket differential available that offers both 100-percent lock-up at the push of a button and the characteristics of a limited slip when disengaged. It can be actuated on the fly at any speed, and it does not rely on shift forks or cables to operate. The unit uses 12-volt DC current and is virtually noise-free.

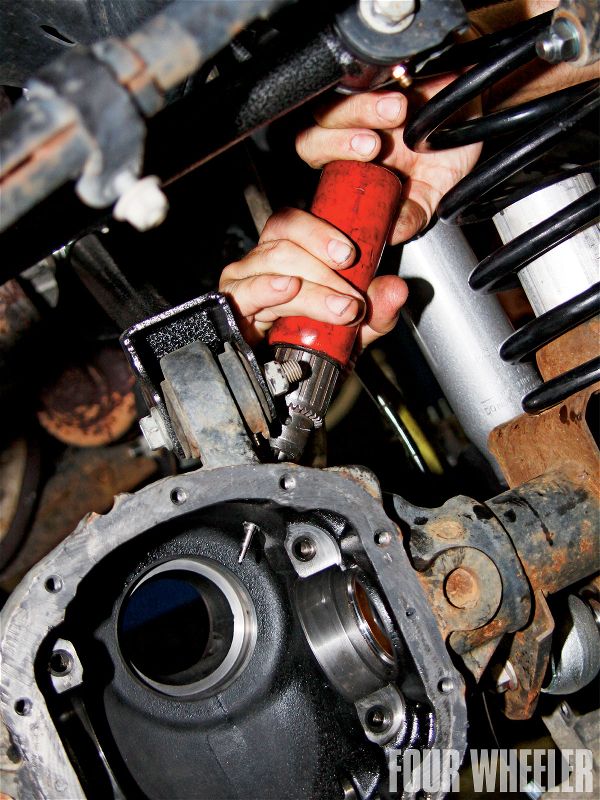

To install the Auburn ECTED Max differential, you must drill a hole in the diff housing for the included two-wire electrical connection and then clean the inside of the housing thoroughly to remove any metal shavings left behind. The good folks at Jack-It in Salt Lake City, Utah, performed this process for us.

To install the Auburn ECTED Max differential, you must drill a hole in the diff housing for the included two-wire electrical connection and then clean the inside of the housing thoroughly to remove any metal shavings left behind. The good folks at Jack-It in Salt Lake City, Utah, performed this process for us.

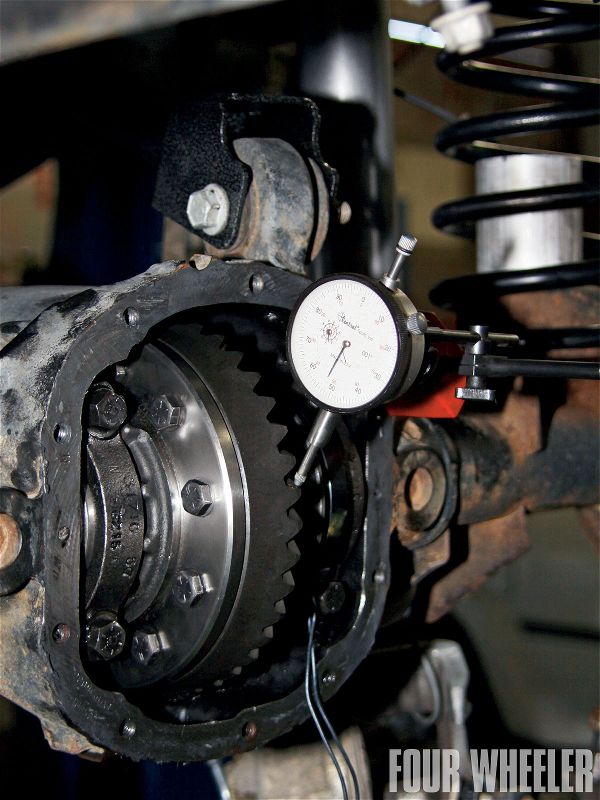

Setting up the wear pattern of the new Superior gearset is next. Using a dial indicator to achieve the proper backlash is a crucial step. Too much backlash will cause excessive wear on the outer edges of the gear. Too little backlash will increase friction and overheat the gears quickly. The ideal gear pattern is centered between the face and the flank of the ring gear teeth; this ensures long life and noise-free operation.

Setting up the wear pattern of the new Superior gearset is next. Using a dial indicator to achieve the proper backlash is a crucial step. Too much backlash will cause excessive wear on the outer edges of the gear. Too little backlash will increase friction and overheat the gears quickly. The ideal gear pattern is centered between the face and the flank of the ring gear teeth; this ensures long life and noise-free operation.

With a bulletproof set of gears and a selectable locker to match, the next rational place to focus our attention was the axleshafts. For those who want to run 35-inch-or-taller tires on a model 30 front end, we strongly suggest installing a pair of Superior's Super 30 chromoly axleshafts because they offer vast improvements in strength over stock. The OE axleshafts on the JK Dana 30 feature 27 splines whereas the Super 30 shafts come with 30 splines. Typically, each spline represents an 11-percent increase in overall strength. Combine that with the added strength of chromoly steel material, and you have a much more reliable axle arrangement for your JK.

With a bulletproof set of gears and a selectable locker to match, the next rational place to focus our attention was the axleshafts. For those who want to run 35-inch-or-taller tires on a model 30 front end, we strongly suggest installing a pair of Superior's Super 30 chromoly axleshafts because they offer vast improvements in strength over stock. The OE axleshafts on the JK Dana 30 feature 27 splines whereas the Super 30 shafts come with 30 splines. Typically, each spline represents an 11-percent increase in overall strength. Combine that with the added strength of chromoly steel material, and you have a much more reliable axle arrangement for your JK.

If you plan to go bigger than 35 inches, you should consider CTM U-joints for ultimate reliability. CTM joints start out as a billet chunk of 300M tool steel. From there, the material is CNC-machined to precise tolerances in the shape of a U-joint cross. The setup is much stronger than a typical U-joint because of the material used. The only drawback to these joints is their cost.

If you plan to go bigger than 35 inches, you should consider CTM U-joints for ultimate reliability. CTM joints start out as a billet chunk of 300M tool steel. From there, the material is CNC-machined to precise tolerances in the shape of a U-joint cross. The setup is much stronger than a typical U-joint because of the material used. The only drawback to these joints is their cost.

CTM U-Joints use a bronze sleeve in place of needle bearings. It is important to keep these sleeves well greased using a needle adapter on a regular grease gun. We greased the joints shown here prior to installation. To date, we have racked up more than 7,000 miles of street and trail use without additional greasing and have had no trouble or noise to speak of. The good folks at Extreme Gear in Rancho Cordova, California, performed this installation for us.

CTM U-Joints use a bronze sleeve in place of needle bearings. It is important to keep these sleeves well greased using a needle adapter on a regular grease gun. We greased the joints shown here prior to installation. To date, we have racked up more than 7,000 miles of street and trail use without additional greasing and have had no trouble or noise to speak of. The good folks at Extreme Gear in Rancho Cordova, California, performed this installation for us.

Installation tip: Sometimes fitting a pair of high-quality chromoly axleshafts with CTM U-joints installed can be tricky. We recommend removing the zerk fittings from the U-joint caps before attempting to install the shafts back into the housing. Once installed, replace the zerk fittings.

Installation tip: Sometimes fitting a pair of high-quality chromoly axleshafts with CTM U-joints installed can be tricky. We recommend removing the zerk fittings from the U-joint caps before attempting to install the shafts back into the housing. Once installed, replace the zerk fittings.

The final place one should focus his or her attention on when bulletproofing the JK Dana 30 is the drive yoke. We upgraded our front and rear driveshafts with stronger units from Tom Wood's Custom Driveshafts in Ogden, Utah. Here you can see the billet flange-style yoke that Tom provided for our build. This type of yoke typically doubles the strength of a traditional strap-style yoke arrangement. The additional strength comes from having more material in key areas surrounding the driveline U-joint.

The final place one should focus his or her attention on when bulletproofing the JK Dana 30 is the drive yoke. We upgraded our front and rear driveshafts with stronger units from Tom Wood's Custom Driveshafts in Ogden, Utah. Here you can see the billet flange-style yoke that Tom provided for our build. This type of yoke typically doubles the strength of a traditional strap-style yoke arrangement. The additional strength comes from having more material in key areas surrounding the driveline U-joint.