When it comes to heavy hauling, most people would agree that the Ford Super Duty platform is probably the most favored of the bunch. Since its inception, annual sales have been staggering at over 200,000 per year. This equates to well over a million Ford Super Duty trucks in service today. The bulk of these were equipped with the 7.3L Power Stroke diesel option, and the great majority of these came with the time-tested four-speed automatic known as the E40D or 4R100. This transmission was suitable for stock power levels (and end users who do things by the book), however, once overloaded or exposed to increased torque loads, both the E40D and 4R100 quickly showed signs of weakness.

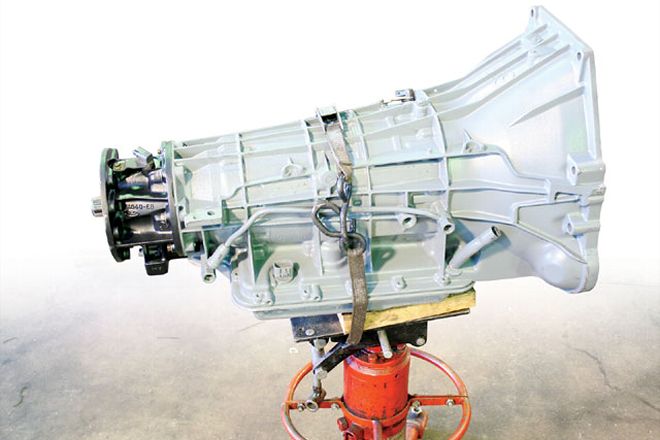

That's why we did a little investigative work to see how these transmissions could be configured to perform reliably under even the most demanding conditions. Our search led us to John Wood Automotive of Holtville, California. Wood started building Ford transmissions in 1983 and prides himself with a reputation for utmost attention to detail and customer satisfaction. Wood operates his business on the principle of quality before quantity, which with only one assistant requires he take on only one transmission rebuild per day. This methodology pays off, as most of Wood's patrons are referred by word of mouth. Diesel drag racing, sled pulling, sand-dune running, and heavy towing are the primary lifestyles of Wood's customers.

Wood has an intensive educational rebuild program that's set up to teach Super Duty owners all the ins and outs of their transmission in one full eight-hour work day. Some customers take notes while others take a rain check and visit the nearby Glamis OHV area, but everybody leaves happy knowing they have the most efficient, reliable, and robust E40D or 4R100 money can buy.

1. Prior to teardown, John conducts a one-on-one interview with each customer to determine exactly how crazy his or her transmission needs are. Ours included heavy towing, occasional sled pulls, and a 50-mile daily commute in stop-and-go traffic.

1. Prior to teardown, John conducts a one-on-one interview with each customer to determine exactly how crazy his or her transmission needs are. Ours included heavy towing, occasional sled pulls, and a 50-mile daily commute in stop-and-go traffic.

2. The first thing Wood explains to customers is where Ford went wrong when they designed the transmission in the first place. Notice the small "bypass" line on the workbench. This line was designed to allow transmission fluid to reach operating temperature quickly after start-up. Basically, it involves an inline check valve that opens up, allowing ATF to bypass the cooling circuit when restrictions are above a specific value, e.g., cold temperatures, or with the addition of extra transmission coolers and/or increased line pressure. This is bad for those of us who like to improve things over stock. Without proper cooling, ATF quickly degrades, causing internal components to wear prematurely.

2. The first thing Wood explains to customers is where Ford went wrong when they designed the transmission in the first place. Notice the small "bypass" line on the workbench. This line was designed to allow transmission fluid to reach operating temperature quickly after start-up. Basically, it involves an inline check valve that opens up, allowing ATF to bypass the cooling circuit when restrictions are above a specific value, e.g., cold temperatures, or with the addition of extra transmission coolers and/or increased line pressure. This is bad for those of us who like to improve things over stock. Without proper cooling, ATF quickly degrades, causing internal components to wear prematurely.

3. One look at the magnet located inside the bottom of the pan confirmed that our donor's transmission had been through the wringer. Excessive heat causes internal clutches and other parts to break down.

3. One look at the magnet located inside the bottom of the pan confirmed that our donor's transmission had been through the wringer. Excessive heat causes internal clutches and other parts to break down.

4. Upon teardown, Wood showed us several worn-out clutch materials. This transmission failed because the owner had recently added an aftermarket programmer designed to increase power over stock. This added power increased the transmission's line pressure, which in turn caused the bypass valve to open up, eliminating the cooling circuit. This quickly caused the transmission to build up excessive heat each and every time the truck was driven.

4. Upon teardown, Wood showed us several worn-out clutch materials. This transmission failed because the owner had recently added an aftermarket programmer designed to increase power over stock. This added power increased the transmission's line pressure, which in turn caused the bypass valve to open up, eliminating the cooling circuit. This quickly caused the transmission to build up excessive heat each and every time the truck was driven.

5. Wood recommends a simple solution to prevent this problem from killing your Super Duty transmission; braze up the small holes in the banjo bolt as seen here. He cautioned us that this procedure must be executed without restricting the center flow-through of the bolt. By closing off these four holes, the ATF bypass tube is eliminated from the system, ensuring the ATF will always go through the cooling circuit.

5. Wood recommends a simple solution to prevent this problem from killing your Super Duty transmission; braze up the small holes in the banjo bolt as seen here. He cautioned us that this procedure must be executed without restricting the center flow-through of the bolt. By closing off these four holes, the ATF bypass tube is eliminated from the system, ensuring the ATF will always go through the cooling circuit.

6. Wood also offers an inexpensive aluminum block-off spacer for those who don't feel confident brazing the holes up themselves.

6. Wood also offers an inexpensive aluminum block-off spacer for those who don't feel confident brazing the holes up themselves.

7. Next, Wood torqued down the center support bolts of the integrated valve body to 14 lb-ft in preparation for resurfacing. These bolts almost always work themselves loose over time, causing internal leakage and low ATF line pressure. Once tightened appropriately, Wood block-sanded the valve-body sealing surface. This resurfacing ensures the valve body will not leak once the transmission is rebuilt. Once perfect, the remaining internals of the transmission were removed from the case and the case was placed in a hot solvent bath.

7. Next, Wood torqued down the center support bolts of the integrated valve body to 14 lb-ft in preparation for resurfacing. These bolts almost always work themselves loose over time, causing internal leakage and low ATF line pressure. Once tightened appropriately, Wood block-sanded the valve-body sealing surface. This resurfacing ensures the valve body will not leak once the transmission is rebuilt. Once perfect, the remaining internals of the transmission were removed from the case and the case was placed in a hot solvent bath.

8. While the case was being cleaned, Wood showed us some of the various parts he uses to firm up shifts inside the 4R100 valve body. Depending on customer needs, Wood replaces valve-body internals with parts from TransGo, as well as a few custom machined items not shown.

8. While the case was being cleaned, Wood showed us some of the various parts he uses to firm up shifts inside the 4R100 valve body. Depending on customer needs, Wood replaces valve-body internals with parts from TransGo, as well as a few custom machined items not shown.

9. Here are two very different converter clutch pistons. The top piston is the OE stamped-steel piston. Below is Wood's custom-made billet piston. Aside from sealing better, this improved piston will not warp or flex. This little touch helps apply equal pressure to the torque-converter clutch, which also helps prevent torque-converter failure.

9. Here are two very different converter clutch pistons. The top piston is the OE stamped-steel piston. Below is Wood's custom-made billet piston. Aside from sealing better, this improved piston will not warp or flex. This little touch helps apply equal pressure to the torque-converter clutch, which also helps prevent torque-converter failure.

10. These are three different converter clutch materials found in the 4R100 transmission. The one on the outside is a competitor's brand. The one in the middle is the stock clutch material. The one on the inside is what Wood uses in all his rebuilds. Notice how thick the disc and outer engagement teeth are. This increase in thickness, as well as tooth count, adds strength and helps Wood's transmissions stand up to higher torque loads.

10. These are three different converter clutch materials found in the 4R100 transmission. The one on the outside is a competitor's brand. The one in the middle is the stock clutch material. The one on the inside is what Wood uses in all his rebuilds. Notice how thick the disc and outer engagement teeth are. This increase in thickness, as well as tooth count, adds strength and helps Wood's transmissions stand up to higher torque loads.

11. Here again are the three converter clutch materials. Notice the difference in color between the Wood unit and the other two. The reason for this is that the Wood clutch is made from a special high-energy material that is super-expensive and long-lasting.

11. Here again are the three converter clutch materials. Notice the difference in color between the Wood unit and the other two. The reason for this is that the Wood clutch is made from a special high-energy material that is super-expensive and long-lasting.

12. This picture shows the inside of the torque converter Wood installs with each high-performance transmission. This torque converter features furnace-brazed fins and bearings throughout to increase durability.

12. This picture shows the inside of the torque converter Wood installs with each high-performance transmission. This torque converter features furnace-brazed fins and bearings throughout to increase durability.

13. Here you can see the difference between a stock torque converter and the Wood unit. The front cover of the Wood unit is a billet-machined piece. This prevents converter housing flex, as well as eliminates the possibility of the converter separating from the flexplate.

13. Here you can see the difference between a stock torque converter and the Wood unit. The front cover of the Wood unit is a billet-machined piece. This prevents converter housing flex, as well as eliminates the possibility of the converter separating from the flexplate.

14. Wood replaced each and every high-wear washer (front) with high-quality Torrington bearings (rear). This reduces transmission drag and easily doubles the service life of the parts.

14. Wood replaced each and every high-wear washer (front) with high-quality Torrington bearings (rear). This reduces transmission drag and easily doubles the service life of the parts.

15. Shown here are just a few of the internal clutches Wood replaces during the rebuild process. He only uses factory-type materials because when properly lubricated, these clutches almost always outlast any other aftermarket-type materials. We couldn't give away any secrets, but Wood told us that each and every clutch cluster receives additional friction materials.

15. Shown here are just a few of the internal clutches Wood replaces during the rebuild process. He only uses factory-type materials because when properly lubricated, these clutches almost always outlast any other aftermarket-type materials. We couldn't give away any secrets, but Wood told us that each and every clutch cluster receives additional friction materials.

16. This is just one of many billet-shaft upgrade options Wood offers his customers. This one happens to be a 300M input shaft for the 4R100; in addition, he also offers intermediate and output shafts that are each load-tested to 2,200 lb-ft of torque. These are only necessary for drag racing, sled pulling, and other extreme applications.

16. This is just one of many billet-shaft upgrade options Wood offers his customers. This one happens to be a 300M input shaft for the 4R100; in addition, he also offers intermediate and output shafts that are each load-tested to 2,200 lb-ft of torque. These are only necessary for drag racing, sled pulling, and other extreme applications.

17. The 4R100's center support (shown) is the most common culprit when it comes to transmission failure. For this reason, Wood spends a lot of time machining down this aluminum part so that a steel snap ring can be installed in front of it. The steel then becomes the wear surface instead of the aluminum. We don't expect you to visualize this unless you've seen the inside of a 4R100; just know that this simple step is one of many machining processes each Wood transmission undergoes.

17. The 4R100's center support (shown) is the most common culprit when it comes to transmission failure. For this reason, Wood spends a lot of time machining down this aluminum part so that a steel snap ring can be installed in front of it. The steel then becomes the wear surface instead of the aluminum. We don't expect you to visualize this unless you've seen the inside of a 4R100; just know that this simple step is one of many machining processes each Wood transmission undergoes.

18. After reassembly, Wood replaced the '99 OE transmission cooler found under our donor's truck with the improved type found on newer 6.0L trucks. As you can see, the difference in surface area is obvious; this resulted in a 30-degree temperature drop verses the smaller unit's 15. This upgrade is nice because it bolts on easily in the same location, and uses genuine factory Ford parts.

18. After reassembly, Wood replaced the '99 OE transmission cooler found under our donor's truck with the improved type found on newer 6.0L trucks. As you can see, the difference in surface area is obvious; this resulted in a 30-degree temperature drop verses the smaller unit's 15. This upgrade is nice because it bolts on easily in the same location, and uses genuine factory Ford parts.

Each and every transmission Wood rebuilds also receives a brand-new factory Ford Super Duty radiator. This is always necessary because, once contaminated with clutch material, it's almost impossible to get the same efficiency from the built-in transmission cooler. In the case of '99 trucks, Ford didn't include a built-in transmission cooler with the radiator. This is part of the reason why they had that silly bypass circuit with the check valve shown earlier. In '00-and-later Ford Super Duty trucks, they improved this design and included a separate circuit for ATF temperature regulation at the bottom of each radiator. This design helps bring the ATF up to normal operating temperature at initial start-up. It also helps cool the ATF under extreme conditions.

Another service John Wood offers his customers is custom ECU tuning via SCT's performance interface and computer software. We had him tune our donor's truck for improved power and higher top speed, as well as speedometer calibration settings for 40-inch tires. In addition, this software can take out power for improved reliability in fleet trucks or set a speed governor for teenage drivers. Our donor really liked the performance gains this retune provided for his truck. In fact, it worked so well, he decided to get rid of the plug-in tuner that caused his troubles in the first place. After over 1 1/2 years and nearly 29,000 miles on the Wood-prepped transmission, our donor is very happy and still enjoying his Ford Super Duty's newfound reliability and performance. The cost of this rebuild was not inexpensive, but considering what you get for the money, we feel it's one of the best programs available for the 7.3L Ford Super Duty owner.

For those of you who don't need to spend a fortune on transmission performance like our donor did, but still want to tow reliably with up to 350 hp, Wood has an option for you too. This year, he came out with a new rebuild program where he guarantees his work for 75,000 miles or three years, whichever comes first. This program was designed for the average Joe who simply has an intake, exhaust system, and/or a programmer. The price for the Towmaster rebuild is $3,600-not bad, considering the average dealership rebuild is around $3,800.