When it comes to choosing transfer cases, the NP205 has always been known as the king of strength. From big-truck mud bogging with 44s to stadium sled pulls, the 205 is the transfer case that answers the call when nothing else will do. Fitted in Chevy, Ford, Dodge, and International pickup trucks during the '70s and '80s, these units are compact, geardriven, iron-cased, no-nonsense, and reliable workhorses of the 4x4 world. As good as this unit is, the drawback to the 205 is the poor gear reduction in low range. With a stock reduction ratio of less than 2:1, the crawling capability for the 205 is nothing to rave about. It's adequate for most trail usage, but lower gears have been on the wish list of wheelers for years. Other popular but lighter-duty transfer cases such as the Dana 300 and Dana 20 have been the lucky recipients of lower aftermarket gears, even though they came stock with better ratios than the 205. The reason that lower gearsets (which have larger-diameter gears) have not been made for the 205 is that the stock case is simply too small-the larger low-range gears won't fit inside.

Luckily, JB Conversions has countered the case size limitation by making a brand-new design nodular-iron case, as well as the larger LoMax 3:1 gears that go inside it. JB Conversions began offering high-strength gearsets for the Dana 300 several years ago with great success, also marketed under the LoMax name. We featured these gears in "Super 300 Transfer Case" (June '04) and have been extremely pleased. But for big trucks or high-horsepower applications, the 205 with these new low gears is the way to go. You won't need a LoMax 205 in a Suzuki or competition buggy but for a 7,000-pound mud truck, swamp buggy, or sled puller, this would be the ticket. It is only when you step beyond heavy duty into the severe and nasty four wheeling that you experience the requirement for a LoMax 205.

The LoMax kit comes with a new case, cover, and five full gearsets. To keep the cost down the new case accepts all of your original New Process parts such as output shafts, shift rails, and bearing retainers. However, complete new units are available if you don't have an NP205 already. If you are installing a LoMax 205 in an existing stock application, there are no speedometer, floor board, tranny mount, or driveshaft modifications needed to accommodate it. What this means is no other cash to spend. Other aftermarket transfer-case installations can cost several thousand dollars more considering new adapters, driveshaft, exhaust work, and the like. There is absolutely no fabrication required to install the LoMax 205, and single- or twin-stick kits are a available as well. On the downside, for now the new case is configured for GM passenger-side applications only. Cases for the Ford guys will hopefully follow soon.

Since a lower low range always ranks high on the four wheelers list of "must have" upgrades, running the numbers of both ratio and cost is important. If you change ring-and-pinion ratios from a 3.73 to a 5.58, that percentage of gear reduction is about the same as changing your 2:1 NP205 to a 3:1 LoMax 205. However, you still retain the 3.73 high-range axle ratios, instead of trundling around with deep axle gears when you don't need them. In addition, the cost for the LoMax kit is around $1,100 at press time (and less than $2,000 for a complete unit), while changing axle gears could easily cost you that, and other whole transfer cases even more. We plan to install a LoMax 205 in a truck in the next few months, but we asked John White of JB Conversions for some photos and tech info for this story, to get you the information before we even build our own truck. Check out the detailed info below, and see why we're getting our own LoMax 205.

The secrets to the strength of the LoMax design are no different from those credited to the original New Process design. The shaft designs and bearing positioning in the 205 are entirely different from other stock and aftermarket transfer cases. First, the long shaft extension (A) on the rear of the LoMax input gear allows the supporting needle bearings (B) to be positioned in line with the rear support bearing (C) for the output shaft (D). This lineup harnesses gear thrust loads and forces them to react directly at the widest possible support points, therefore eliminating any chance for shaft misalignment. This shaft design is only found in the New Process and LoMax line.

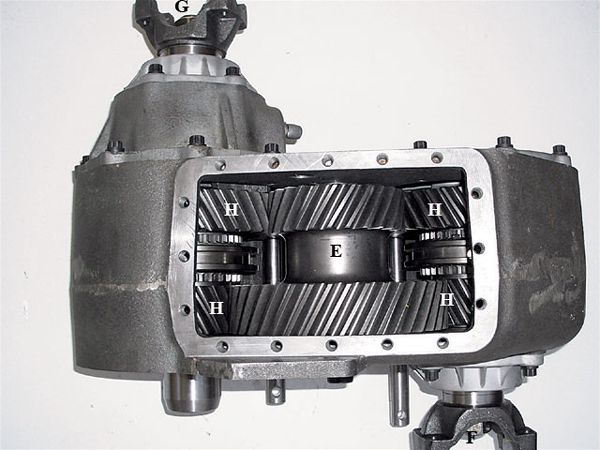

Secondly, the 205 design uses tapered roller bearings on each end of the intermediate gear (E). Tapered roller bearings are used here because of axial thrust loads trying to push the gear forward or backward against the case wall. Helical gear teeth produce those types of loads, but typical transfer cases use small needle bearings coupled with thrust washers in these locations. The tapered roller bearings allow the gear forces to greatly exceed the capacities of the thrust washer design. However, the forces on the front (F) and rear (G) output shafts produced by the mating gear teeth (H) need bearings that can support large radial loads. The load capacity of the ball and straight roller bearings thrive in severe radial load applications where tapered roller bearings don't. Smaller transfer cases use tapered roller bearings on the output shafts successfully due to lower gear loading found in their applications.