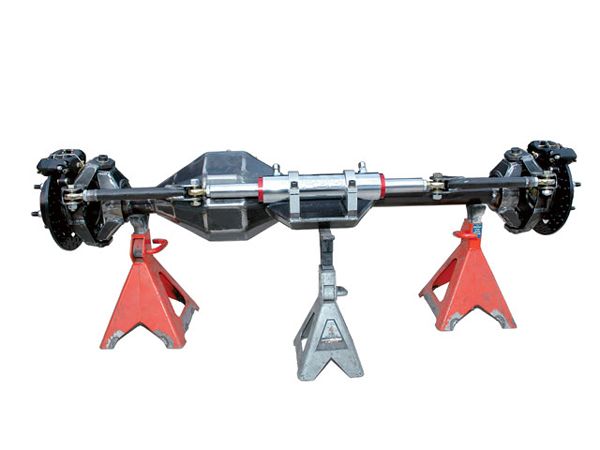

Everyone in need of one has heard of a Dana 60 front axle. The problem is they don't exactly grow on trees. Both custom and junkyard versions are available, but neither is cheap. If you want good beef, you pay for it! However, Spidertrax Off-Road has found a way to knock down some of the costs for a hefty but lightweight (318 pounds with our steering) Ford 9-inch front axle with plate steel knuckles.

The Spider 69 front axle starts with a Spider 9 housing custom made out of 3/16-inch plate steel by Spidertrax. The housing boasts more clearance than both the traditional Ford 9-inch, as well as some other aftermarket shaved units. The numerous bends in the housing plates help make it extremely rigid. The knuckles are also made from plate steel and feature uniballs instead of ball joints. The uniballs are extremely strong. However, we feel those in wet states may be better off with a typical ball joint or kingpin-style axle with seals because the uniballs are better suited for dryer areas. The plate knuckles offer endless steering possibilities and can be built to accept Dodge unit bearings or Ford Superduty outers for those who want locking hubs.

Mounting suspension components and steering is made simple because there is no cast material in the entire housing. It's all easily welded plate steel and heavy-wall tubing.

PhotosView Slideshow

PhotosView Slideshow