<p>

<p>

If you made a list of the most outstanding cars of 2004, ThunderRoad would be on it somewhere. This sweet little '29 pickup, built by POSIES Rods and Customs and featured on the December '04 cover of this magazine, runs over ambiguous and divisive labels such as "traditional" and "contemporary" on its way to redefining the only label that really means anything: "hot rod."

One of the most attention-getting components on this overall attention-getting rod is the 500hp Roush 402IR engine, backed up by a Deltrans-built 700-R4 transmission. The ingredient that makes the big Roush mill work with the four-speed automatic overdrive gearbox is a transmission adapter from Wilcap.

Wilcap is one of the longest-operating businesses in hot rodding. The company has been around since the '40s, when Tony Capanna and Red Wilson began manufacturing parts for the emerging performance car market, specializing early on in engine-to-transmission adapters for various applications. Capanna's interest also extended to other areas, specifically fuels and fuel economy. Tony worked with several partners over the years, including his son, Lloyd, who eventually helped run the company. Tony and Lloyd both passed away in 2001. One year later, Wilcap was sold to Pat McGuire. Under McGuire's ownership, Wilcap continues to offer several different product lines, but once again specializes in transmission adapters.

As Tony Capanna knew 60 years ago, and McGuire knows today, hot rodders have been mixing and matching engine and transmission combinations from the get go. When Flatheads were the prominent powerplant choice for hot rods, enthusiasts put a lot of time and energy into building up these engines, but beyond adding Zephyr gears to the '39 tranny, they made very few modifications to the transmissions, which made trying to keep up with the beefed-up mill a real chore. A solution was to replace the stock box with a Cad LaSalle, Lincoln, or other transmission not engineered to work with the Flathead. By the '50s, overhead valve engines started moving in on the dominance of the Flathead. Hot rodders, ready for something new, eagerly dropped Nailheads, Olds Rockets, Cadillacs, Hemis, and Chevy small-blocks into their Deuces, Model As, '40 Fords, and '50 Mercs, adapting most of them to an earlier transmission.

Today, out-of-the-ordinary engine and tranny combinations aren't that out of the ordinary. McGuire is able to sort requested applications into three general categories. The largest category nowadays is the hot rodder who wants to run an older engine, such as a Flathead or early OHV, primarily for the traditional appearance, but back it up with a more highway-worthy modern transmission, such as the 700-R4 (which is probably the most popular gearbox choice).

The second category is the rodder who's doing an engine swap, but doesn't want to make any changes to the rest of the drivetrain. Instead he chooses to adapt the original transmission to the new engine, maybe due to an enclosed driveline, or because the car is already well set up for the original drivetrain, or the fact that swapping an engine is a lot less complicated than swapping a transmission.

The third category covers pretty much everything else. It might be a guy with a small-block Chevy in one corner of the shop and a 727 Chrysler transmission in another corner who wants to build a rod using the stuff he's already got, or it could be the rodder who likes to build oddball combinations, in McGuire's word, "just because they can." POSIES' Roush engine and 700-R4 match-up would fall into this classification.

"> <p>

<p>

Within those three fundamental groups are a million other variations. Maybe not a million, but multiply the number of different engines by the number of different transmissions and you'll get the precise total. It's a big number. Wilcap isn't the only company building adapters to mate mill to gearbox, but with approximately 50 of the more typical applications currently available, it's one of a small number of companies with such a broad offering. And with new applications being developed at the rate of about one a month, Wilcap is growing fast. We get the feeling that McGuire won't rest until he can get every possible combo into his catalog.

Judging by Wilcap customers, the most popular engines being adapted are small-block Chevys (to early Ford transmissions), Flatheads, and Hemis (which are extremely popular right now). Wilcap gets requests for every Hemi variety: Dodge, Chrysler, DeSoto, the new 5.7 version, and even imports such as Daimler and Toyota versions.

Although the function of a transmission adapter is incredibly simple--it provides the mechanical interface between an engine and transmission that were not originally designed to go together--the process involved in developing an adapter for a new application is complicated and time consuming. The CNC machines that have replaced drill jigs in just the last few years have made the physical manufacturing process a lot more efficient and economical. In addition, they have improved the potential for quality, precision, repeatability, precision, and flexibility.

"The ideal situation," according to McGuire, "would be that a customer calls you up and says 'I want to run this engine with this transmission,' and even if it's some combination you've never done before, you could walk over to the CNC, push a button for the engine, hit another button for the transmission, and let the machine take care of the rest." Unfortunately, it's not quite that miraculous. For the time being, the process of building a transmission adapter still relies on a lot of research and development on the part of good old-fashioned human beings.

Making A Transmission Adapter

In the old days (10 years ago), developing a transmission adapter for a new application required a lot of background research and hands-on measuring. Today, it still does, even with CAD and CAM technology, and CNC machining greatly streamlining the effort.

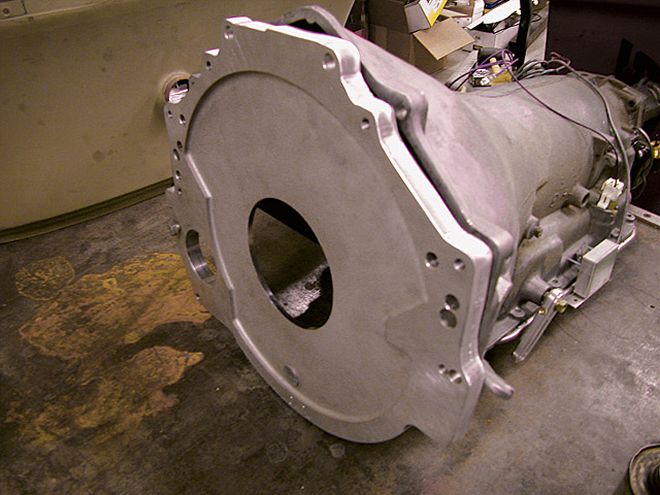

POSIES ThunderRoad '29 Ford is powered by a race-prepped fuel-injected Roush 402 Ford motor, tied to a GM 700-R4 AOD transmission. The Wilcap adapter matches engine to gearbox perfectly.

POSIES ThunderRoad '29 Ford is powered by a race-prepped fuel-injected Roush 402 Ford motor, tied to a GM 700-R4 AOD transmission. The Wilcap adapter matches engine to gearbox perfectly.

The biggest difference, McGuire told us, is that in the old days, there was far less flexibility. Once a pattern was made and a part was cast from it, it was a lot more difficult to make any adjustments. The greatest contribution of CAM and CAD systems is that you can develop casting without actually having to have every single engine and transmission combination on hand in order to make a trial run. A solid model can be built into the CAD program, which can be further tweaked according to changing criteria, such as the position of the starter, frame clearance, or engine mounts. Manufacturers are moving away from having to crawl around underneath the car to take measurements and make notes. "The new technology has improved how much we can accomplish," McGuire explains. "It's gotten almost to the point where building a production item and building an adapter from scratch are the same amount of work."

One thing that hasn't changed much is the amount of preliminary work that goes into developing an adapter for a block. Once an engine and transmission are acquired, preliminary drawings of the back of the engine are created in order to determine the applicable dimensions, which includes crankshaft dimensions, the oil pan, and other components that could interfere with the fit of the adapter.

McGuire spends a lot of time on the Internet and phone talking with club members, chat room participants, collectors, and other professional and hobbyist experts on particular engines, garnering such information as when did that particular block begin production, when did it end, and what various configurations were available.

Wilcap has approximately 35 popular early engines, and an equal number of transmissions on hand to use as samples. "We have to make sure we're working from good engines, preferably one that has never been apart and is mated to the original transmission. You learn to spot motors that might have a problem. A typical indication of that would be abnormal wear on the crankshaft flange. With a manual transmission, it could be a worn-out pilot bearing. We really love to find a good motor with 150-to-200,000 miles with nothing wrong. But you're taking an engine that was maybe produced for 15 years and hoping that you didn't get the one that was made on Friday afternoon."

As important as finding a good engine sample is knowing the potential various configurations of that engine over the years that would affect fitting an adapter. Knowing those variations is an important component in developing a large and successful inventory of adapters.

"Take the Hudson, for example. We found out that on the 308ci six-cylinders, the crankshafts were different on the engines used with automatics than on the ones used with manuals. Another example: In 1963, Pontiac started to mount the starter on the block like Chevrolet had been doing. So there are some Pontiac blocks manufactured during the year that are drilled and some that are not. In addition, there is a bigger register on the back of the crankshaft and a difference in the distance the crank sticks out. Everything that ever came out of Detroit was subject to change at any moment, and once an engine has been pulled from a car, it can get difficult to track that kind of thing. That's when we have to ask the customer to go out and take some measurements to determine exactly what he has."

Wilcap has been around since the mid-'40s, and has been under new ownership for three years. The company's inventory of adapters for early and late manual and automatic transmissions is large and getting larger.

Wilcap has been around since the mid-'40s, and has been under new ownership for three years. The company's inventory of adapters for early and late manual and automatic transmissions is large and getting larger.

Slight variations can also be found in virtually every bellhousing, so McGuire works from in-house drawings rather than relying on factory drawings. Once all the necessary dimensions have been determined and drawings have been made, a prototype part can be built, and fit. At that point, Wilcap does a final check to make sure nothing was missed. If it was, that's changed. If not, the part is produced.

Installing One

McGuire reminded us that there are still a bunch of hot rodders who grew up dropping a Chevy small-block into a '40 Ford or a Nailhead into an early Ford back in the day. For these experienced old-timers, hooking up non-factory engine and transmission combinations was no big deal. On the other hand, he emphasized several times to us that it's easy to underestimate the amount of work involved in an adapter installations, and that this is not really a job to be tackled by an amateur.

Wilcap doesn't do installations, but works with several transmission shops in developing products, and strongly advises its customers, especially those with less mechanical experience, to hook up with a reliable tranny shop, fabrication shop, or at least some reliable help--maybe one of those old-timers who can remember how he did it 40 years ago.

The level of difficulty is greater if you're swapping the transmission than it is if you're simply changing the engine. The former situation requires pulling the transmission out of the car, dropping the rear crossmember, swinging the driveline out of the way, and undoing all linkage. Once the back of the engine is accessible, it has to be cleaned, and all bolts and dowel pins checked to make sure they are all present and accounted for--and in good shape. After positioning the adapter, it is critical to make sure it sits flush and stays parallel, according to the installation instruction manual.

Once the adapter has been installed, the crankshaft hardware is bolted back on, and the starter is reinstalled and properly engaged. The driveshaft and crossmember are reinstalled (or fabricated, if necessary), along with the speedometer and other linkage.

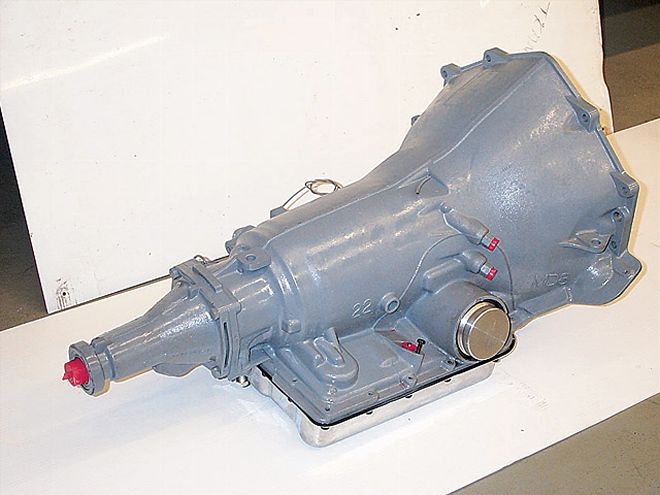

Wilcap handled the adaptation of a Chevy Turbo 400 into a '62 Cadillac, typical of a mid-'50s to mid-'60s installation, according to Wilcap owner Pat McGuire. Work, which was performed at Trans King in Arroyo Grande, CA, included the starter wiring, trans cooler lines, kick-down connection, linkage, rear transmission mount, driveline, and the shift indicator.

Wilcap handled the adaptation of a Chevy Turbo 400 into a '62 Cadillac, typical of a mid-'50s to mid-'60s installation, according to Wilcap owner Pat McGuire. Work, which was performed at Trans King in Arroyo Grande, CA, included the starter wiring, trans cooler lines, kick-down connection, linkage, rear transmission mount, driveline, and the shift indicator.

If the rotating assembly has been balanced on the engine, and the old balanced flywheel is being replaced by the adapter flywheel or flexplate, the new part should be match-balanced to that engine to ensure that when it is installed, there is no change to the engine balance. Even if the adapter is within factory tolerance for balance, McGuire recommends making the effort to make sure the new piece is identically balanced.

Our final question to Wilcap regarded common mistakes made by customers attempting a first-time trans adapter installation. To put it more kindly, what common challenges are part of a typical installation? McGuire pointed out several frequently encountered problem areas. A primary consideration, which we've already mentioned, is fitment. The starter is the most common culprit, but the steering box, exhaust, frame, and other components can also be affected by adding an adapter to the driveline.

The driveshaft position is another common critical area. Since the addition of an adapter can alter the angle of the engine and transmission, be sure to check the output shaft and pinion angle, driveshaft, and rearend. On automatic applications, the torque converter pull-back distance is another consideration. Check that the proper distance between the flexplate and the converter is maintained. On manual applications, McGuire recommends using a bushing to protect roller bearings, which are fragile and can be damaged during installation. Far less common goof-ups include easily avoidable situations such as mounting the flexplate incorrectly, or backward. Beyond that, the most general goof-up is simply not following instructions.

Five For FlattiesFord Flatheads, the powerplant staple in the hobby for many years, are still venerated by traditionally oriented rodders who consider all OHV motors "high-tech," and don't show any sign of going away. Many of the Flatheads in service today, however, have been paired with later transmissions, more suitable to 21st century transportation than the original Ford three-speeds. A few companies have been paying close attention to this trend. One in particular, Cornhusker Rod & Custom, built a business around hooking Flatheads to Borg Warner T5 transmissions. Among the many advantages of the new tranny over the old are the two additional forward gears--including overdrive--and the closer gear ratio better suited to the engine. Combining a traditional-looking mill with up-to-date cruisability and performance is now a thing of the present.Cornhusker has put all necessary parts for adapting this popular traditional engine to a newer transmission single package, which includes bellhousing, throwout bearing, pilot bushing, cross shaft, and optional adapter for 59A and earlier applications. Gary Mussman at Cornhusker can tell you all about it, if you give him a call.

By: Jim Aust & Kevin leePhotography by: Kevin LeeThe Oldest Trick In The BookSince the introduction of the Chevy small-block, creative rodders have been stuffing them into just about every engine bay imaginable. The most popular of all the swaps has to be the venerable bow-tie mill in front of an early Ford driveline. Years ago you could round up the necessary pieces from your local speed shop and wrecking yards without too much effort, but today those pieces are not so readily available. However, thanks to Wilcap you won't need to spend hours tracking down vintage parts of questionable condition.

With one simple phone call to Wilcap you can get brand-new pieces to adapt any GM small-block to an early Ford transmission like so many rodders before you. This was the case when Editor Kevin wanted to upgrade a few components in the driveline of his longtime family-owned '32 Ford roadster and found it much easier to dial up Wilcap than try and track down all the necessary pieces himself.

The parts made the mating a snap and got our editor and his roadster back on the road where they both belong.