OK, now let’s get this straight—within every Mustang beats the heart of a Falcon: Same shock towers, virtually identical control arms, spring perches, springs, shocks, and grocery-getter leaf springs. And we expect them to handle without much help. Ford boss Robert McNamara’s utilitarian Falcon was neither designed nor engineered to be a sporty car. It was developed to be basic transportation for a family of six, nine if you bought a wagon.

Ford hung sporty good-looking skin on the Falcon’s bones and it still had an economy sedan with flimsy upper control arms and camber and caster adjustment via shims you either added or subtracted to get the settings you wanted. This made for a very frustrating frontend alignment experience. Strut rods were fixed those first two model years. Toe was adjusted via tie-rod ends much as it has always been. Beginning in 1967, Ford went to adjustable eccentrics on the lower control arms, which made camber adjustments a snap. Adjustable strut rods made caster adjustment straightforward for technicians.

Over the past 20 years, the automotive aftermarket has developed sophisticated suspension systems for classic Mustangs. Much of it began with modified factory upper and lower control arms, then fully adjustable tubular control arms with coilover shocks or airbags. Today, companies like Total Cost Involved (TCI) Engineering have developed complete suspension systems for classic Mustangs that will make your vintage Pony drive and handle like never before; and that’s because the TCI system completely eliminates your Mustang’s outdated spring-over-upper arm system. What’s more, TCI Engineering manufactures its suspension system here in the United States under very strict engineering standards that ensure you’re getting the very best TCI Engineering has to offer.

TCI Engineering’s roots lay in street rods beginning way back in 1974 when street rodders needed well-engineered frames and suspensions for Ford Model A hot rods. President and Founder Ed Moss tells Mustang Monthly, “Total Cost Involved Engineering began to set the standard for quality when we built those first reproduction Model A frames.” He added, TCI Engineering took the classic car restoration market by storm. They have earned numerous design awards, including the coveted Manufacturer of the Year award from SEMA and the SRMA.

We’re going to show you what’s available from TCI Engineering for classic Mustangs and how to install these systems, thanks to help from Stang-Aholics, using a customer’s ’67 Mustang project car.

TCI Engineering Up Front

The first step toward extraordinary handling is to completely remove the classic Mustang’s original front suspension and opt for a more conventional system you can tune for your driving style. The challenge with factory suspension systems is limited alignment capability. TCI Engineering’s ’64½-’70 Ford Mustang—Standard Custom Independent Front Suspension—is not a bolt-in swap, but instead a completely new suspension system you weld to the existing framerails.

’64½-’70 Ford Mustang— Standard Custom Independent Front Suspension Features

1. New RideTech single-adjustable shocks

2. Reinforced 3/16-inch-thick crossmember specifically designed to be used with small- and big-block Fords

4. Upper control arm and coilover mount plates

5. 1-inch antiroll bar 11-inch drilled, slotted, and zinc-plated rotors

6. New big-bore calipers (with 20 percent more clamping force)

7. TCI Engineering designed 2-inch drop spindle or stock height spindle

8. Steel inner fender panels

9. Small-block engine mounts

10. Power rack-and-pinion steering

11.1x0.156-inch-wide U.S. DOM tubular steel upper A-arms

12. Moog K772 upper ball joints

13. 11⁄8x0.156-inch wide U.S. DOM tubular steel lower A-arms

14. Moog K719 lower ball joints

15. Greaseable urethane bushings

16. The rotors, spindles, and brake units come assembled with bearings packed with high-temp grease ready for installation

17. All mounting hardware

18. Instruction manual

In the Rear

TCI Engineering offers you a couple of different rear suspension systems for classic Mustangs, including the torque arm system and the independent four-link coilover system with stabilizer bar. Both systems eliminate the Mustang’s conventional leaf spring package.

What’s This Thing Cost?

For what you get for your money, TCI Engineering chassis and suspension components are an excellent investment. The torque arm suspension package enables you to go racing at any time with complete confidence. You can get into the torque arm suspension for $1,890, excluding tax, handling, and shipping, and not including the 9-inch housing. The IFS suspension package goes for $3,199, excluding tax, handling, and shipping. You’re also going to need engine mounts and brackets, which are extra.

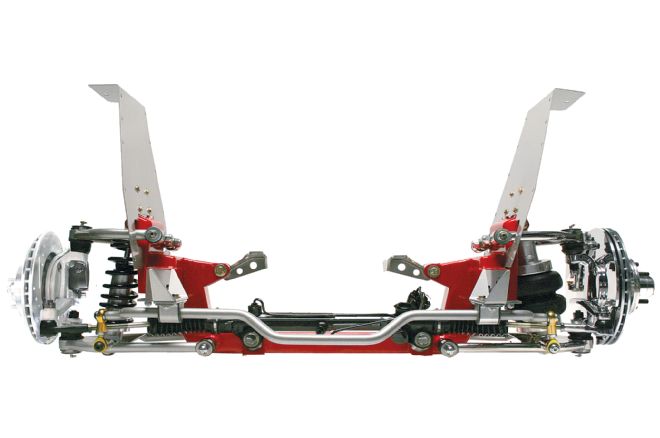

01. TCI Engineering’s ’64½-’70 Mustang Standard Custom Independent Front Suspension is a completely new system you weld to your Mustang’s existing framerail unit body. The existing suspension and shock towers must be removed before this system can be installed. Once installed, the TCI system is a remarkable performer. You will never know how you got along without it.

02. TCI Engineering’s ’64½-’70 Mustang Standard Custom Independent Front Suspension is a completely new system you weld to your Mustang’s existing framerail unit body. The existing suspension and shock towers must be removed before this system can be installed. Once installed, the TCI system is a remarkable performer. You will never know how you got along without it.

03. The Mustang’s factory shock towers are cut out and surfaces ground smooth in preparation for installation of reinforcements.

04. TCI Engineering reinforcements are testfitted and secured in preparation for welding. These reinforcements create a thicker, stronger framerail.

05. TCI Engineering reinforcements are testfitted and secured in preparation for welding. These reinforcements create a thicker, stronger framerail.

06. Once absolute fit is established, Ron Peter of Stang-Aholics welds the reinforcements to existing framerails.

07. Ron fit-checks the TCI Engineering crossmember before permanently welding the framerail reinforcements into place. Once welding is complete and surfaces ground, the crossmember should fit perfectly.

08. This is what the completed crossmember and suspension package looks like, including rack-and-pinion steering. Engine mounts can be set up for nearly anything you’d like.

09. This is the completed suspension installation with adjustable coilover shocks, Wilwood disc brakes, and front steer rack. This is only a mockup. These parts do not come painted, but they are available in either chrome or powdercoat.

10. Upper control arms are fully adjustable (camber and caster) via these adjustment points at the framerail, making it easy to retune alignment for canyon cutting, street cruising, or drag racing.

11. These shock tower replacement panels can be welded or bolted in. This is one of TCI Engineering’s project vehicles where panels are bolted in. Looks sharp.

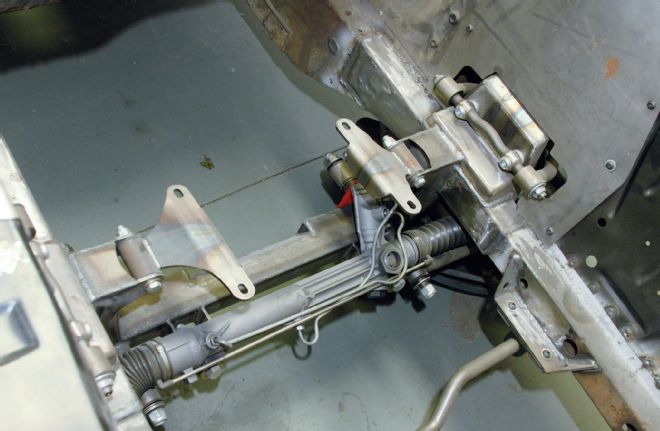

12. The completed installation, including the steering rack, looks like this. We like the compact nature of the TCI Engineering front suspension system for classic Mustangs. It can be adapted for coilovers or airbags.

13. The completed installation, including the steering rack, looks like this. We like the compact nature of the TCI Engineering front suspension system for classic Mustangs. It can be adapted for coilovers or airbags.

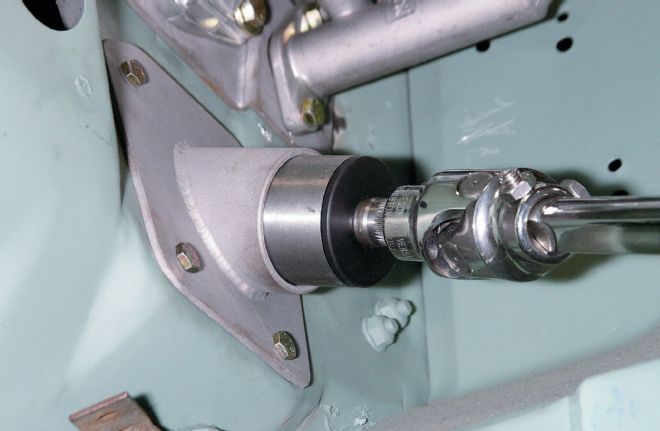

14. This is the firewall steering column mount and steering shaft. Both are easy to fit and install.

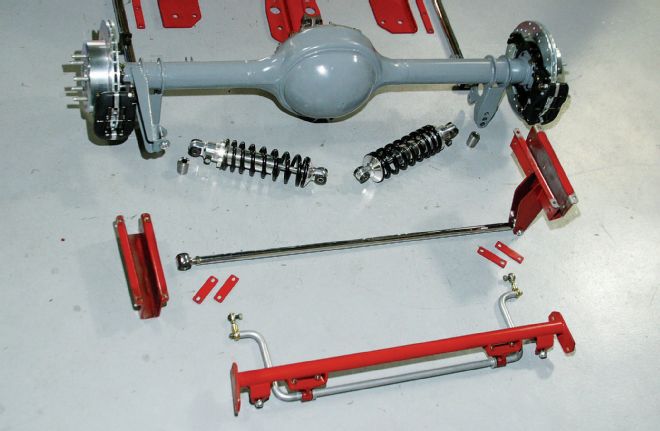

15. This is the TCI Engineering four-link system for classic Mustangs that is a simple bolt-on package, though TCI Engineering recommends that it be welded in place. The four-link provides stability and tuning capability, which means true four-wheel alignment.

16. TCI Engineering’s torque arm rear suspension is an involved installation, but worth it in what you gain in handling and axle stability. The torque arm keeps the axle stable during high-power applications, eliminating axle hop. It is engineered for street, autocross, and road course applications. The torque arm suspension was designed to eliminate the suspension bind that occurs when cornering using the conventional leaf spring suspension. The Torque Arm features a telescoping slider at the front of the arm that rotates as the car goes through suspension travel and articulation. This system can be bolted on, but you’ll still have to weld the axle, Panhard, and antisway bar brackets onto your rearend housing if you don’t spring for the optional 9-inch housing from TCI Engineering.

17. This antisway bar package is part of the torque arm suspension system and is engineered to eliminate body roll. It is fully adjustable for any driving condition.

18. Subframe connectors are installed first, with everything being installed off of these members. You can bolt them on, but it’s a good idea to weld them.

19. Link brackets are next, as shown, with bushings and hardware. Installation is easy. Links are next once the brackets are secured.

20. Link brackets are next, as shown, with bushings and hardware. Installation is easy. Links are next once the brackets are secured.

21. The subframe connectors are bolted to the forward framerails on each side. Though it is bolted here, it is suggested you weld this piece for good structural integrity.

22. The torque arm support assembly is installed next. Bolt this assembly in place instead of welding it, in case it ever has to be removed for maintenance purposes. Check out the driveshaft safety loop incorporated into the frame.

23. The sway bar assembly is next. A cool aspect of this sway bar is its adjustable nature, where you can dial in stiffness or tone it down, depending on the kind of driving you’re going to do.

24. This is the torque arm, which is tied to the Ford 9-inch housing specially designed and crafted for this application. The torque arm is fastened to the third member and axle housing, as shown.

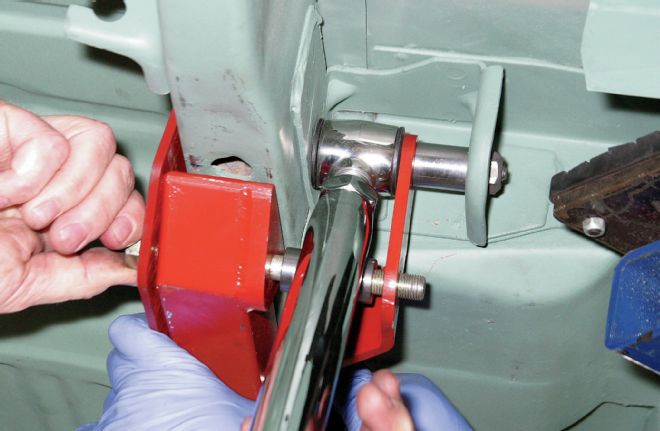

25. Differential pinion angle is adjusted here at the torque arm attachment point using shims (washers) on each side of the torque arm. This makes pinion angle adjustment easy to accomplish in the vehicle.

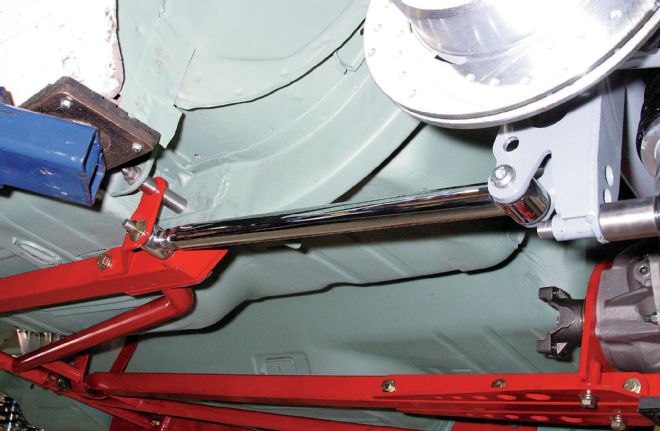

26. The TCI Engineering 9-inch Ford axle and torque arm are installed with the yoke tied to the subframe.

27. The TCI Engineering 9-inch Ford axle and torque arm are installed with the yoke tied to the subframe.

28. With the TCI Engineering 9-inch properly supported, trailing arms and shocks are tied to the axle housing and secured, as shown.

29. This is a two-link suspension with single torque arm (so technically a three-link) for unmatched stability. Adjustable coilover shocks keep rubber intimate with the road.

30. Lastly is the Panhard bar, which keeps the rear axle centered and stable under the toughest driving conditions. Panhard bar adjustment is also part of the four-wheel alignment.