This brake tech guide was written to help you decide which avenue to go down in regard to your Pontiac's brake upgrades. We've talked with some of the biggest names in the performance disc-brake industry, including Brembo, Stoptech, and Wilwood, as well as Master Power Brakes. For Part I, we discuss rotors because there is a lot of ground to cover here. Part II will examine friction materials (pads), calipers, and fluids.

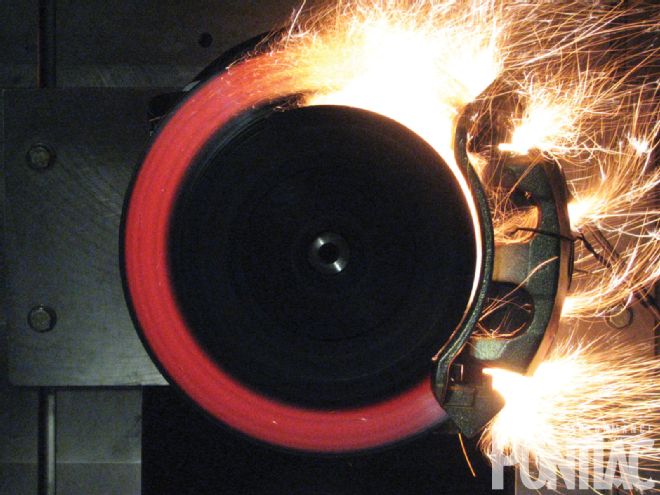

Rotors take a beating under intense braking, as shown by the glowing disc in the photo. The sparks flying out are shards of pad material.

Rotors take a beating under intense braking, as shown by the glowing disc in the photo. The sparks flying out are shards of pad material.

In operation, the brakes slow the rotation of the wheel and tire by converting kinetic energy into thermal energy, thus producing heat. The quest for braking performance involves the braking system's efficiency in dealing with heat and its ability to convert energy. The role of the tires in the braking process cannot be understated, however, as maintaining their grip on the pavement is paramount to stopping your Pontiac.

Before upgrading your brakes, there are a few important factors you should consider: namely, your budget, intended use, and driving style.

Most factory brake systems are designed for competent stopping when cold or hot, and quiet operation. In many cases, these components are not intended for severe use and repetitive stops with great kinetic energy. That doesn't mean you have to buy a six-piston-caliper setup with two-piece rotors. There's a good chance that a simple fluid, pad, lines, and rotor upgrade, like we performed on our '05 GTO, will bring your Pontiac into stop-on-a-dime territory.

Brake Rotors

The brake disc, or rotor, is the surface that is contacted by the pads. When the brakes are appled, abrasive friction is prevalent during lower temperature braking. It's simply the friction caused by the pads rubbing on the surface of the rotor. When temperatures rise, adherent friction comes into play, which is the process by which a thin layer of brake-pad material is transferred onto the rotor surface. This layer of pad material is what rubs on the brake pad.

This is a basic ventilated rotor.

This is a basic ventilated rotor.

Each type of friction allows for conversion of kinetic energy into thermal energy. Abrasive friction, as you may imagine, physically wear the rotors more quickly than adherent friction, but the latter will generally be tougher on the rotor thermally, which leads to heat cracking.

The metallurgy of the majority of rotors is comprised of several grades of cast iron. According to Emanuele Bruletti, Brembo's North American engineer, cast iron is a known metal with stable heat properties, and therefore a good candidate for rotors. The downside to the material is that it's very heavy, which has prompted manufacturers to make rotors out of lighter materials, such as lighter steel, aluminum, titanium, carbon/ceramic, and carbon/carbon. Even among the same materials, there are many rotor configurations available, either off-the-shelf or custom-tailored to your vehicle.

Vented Rotors And Cooling

Since the rotor receives the most thermal energy, or heat, it's very important to control this heat effectively. The use of vented rotors has become more common because the rotor itself features internal cooling passages that work like an impeller. When it spins, air is pulled through the "eye," or center, and is evacuated through the outside of the rotor. A downside to this is the resulting radiant heat-in other words, the rotor will actually heat everything surrounding it.

Ventilated rotors are the only option for a performance braking system. The interior design of the rotor allows air to pass through it, helping to cool the friction surface and the overall braking system. We are showing three different types of cooling vane designs.

Ventilated rotors are the only option for a performance braking system. The interior design of the rotor allows air to pass through it, helping to cool the friction surface and the overall braking system. We are showing three different types of cooling vane designs.

A vented rotor should be the only choice for a performance brake system, since a solid rotor must rely solely on ambient air to control temperature, while the vented rotor is continually moving air through it to better control heat. More air moving across the surface or through the rotor results in increased cooling ability.

Race cars and some street cars benefit from extensive use of brake-cooling ducts to draw cool air onto the rotor surface or rotor eye. This can lower temperatures as much as a few hundred degrees, allowing the brakes to perform better.

"When we set up a brake system for a customer on a race team, brake cooling ducts are fundamental," says Emanuele. "We ask them to focus on the cooling, because cooler rotors allow everything to perform better."

One-Piece Rotor

A one-piece rotor is cast with a hat-the area where the unit is mounted to the hub. Nearly all street cars come with these, and they're perfectly adequate for performance braking but may tend to warp due to thermal expansion. Here's why: When metal is heated, it grows. The diameter of a cast-iron rotor will grow as much as 2 mm, according to Stoptech. A one-piece rotor may be restrained from growing due to its design, which can cause the surface to misshape or warp. That's not to say that all one-piece rotors are the same. Many of the higher-end ones made by credible companies will feature a design less susceptible to this kind of distortion, making them just as effective at preventing it as a two-piece rotor.

Wilwood's one-piece GT Vented Rotor features slots; they are sold as direct replacements for existing disc-brake cars or as a kit.

Wilwood's one-piece GT Vented Rotor features slots; they are sold as direct replacements for existing disc-brake cars or as a kit.

Another downside to the one-piece design is weight. Since it's made of a single piece of like metal, there is no weight saved with the rotor hat. This shouldn't be a concern for cars that aren't going to see serious track time, where you are looking for the most intense performance and every last pound counts.

On the plus side, they're easy to manufacture and are off-the-shelf replacement parts. Many companies like Brembo, Stoptech, Wilwood, and Master Power Brakes make affordable replacement rotors for everything from modern Pontiacs to classics, providing excellent performance on a budget. Each has different features, from cross-drilling to slotted, and different ventilation designs.

Two-Piece/Floating Rotor

The two-piece rotor is the top choice of racers because of its better heat control and weight savings. These advantages are realized in two main ways, the first being the design.

Here is a Brembo two-piece rotor. Notice the way it is held to the aluminum hat.

Here is a Brembo two-piece rotor. Notice the way it is held to the aluminum hat.

Unlike the one-piece rotor with the hat cast into the rotor itself, two-piece rotors feature a separate hat. It's usually made from aluminum, and it allows the rotor to grow uniformly without distorting the friction surface, thereby reducing the likelihood of warping. An aluminum hat also transfers less heat from the friction surface to the bearings.

However, the top reason we find two-piece rotors on nearly all race cars is because they weigh less than one-piece units. Also of note is that the braking band is replaceable; when it wears out, you simple install a replacement.

On the downside, two-piece rotors are more expensive than one-piece. Though some companies may offer them as off-the-shelf parts ready for sale, sometimes they must be pieced together by finding the hat that works for your car and the proper braking band. For the serious racer, two-piece rotors are the best option.

Size And Weight

If thermal efficiency is so important, then when it comes to rotor size, bigger is better, right? Yes, but with some shades of gray.

While cross-drilled and slotted rotors may be "redundant," they have become the staple of the performance look. For its two-piece systems, Wilwood offers high-quality rotors that are resistant to cracking.

While cross-drilled and slotted rotors may be "redundant," they have become the staple of the performance look. For its two-piece systems, Wilwood offers high-quality rotors that are resistant to cracking.

A larger brake rotor has more surface area for the heat to spread across, making it more thermally efficient. This means that your brakes will perform better. The downside to the larger rotor is increased weight, caliper size, and the need for larger wheels. (You can only fit a certain size rotor behind your factory wheels.) Some companies offer low-profile calipers so you can run the largest rotor behind a smaller wheel, which is an excellent option for people looking to upgrade their brake system and retain factory-diameter wheels.

The increased mass is harder to stop, but since there are larger friction surfaces, bigger calipers and pads are used to exploit it. This unsprung weight-components not directly supported by the suspension-is also rotating. This is why two-piece rotors may be a good option, but weight reduction can be taken a step further.

Chevy's new Corvette ZR1 uses 15.5-inch, two-piece carbon/ceramic rotors made by Brembo. Carbon/ceramic material, or CCM, is a technology pioneered in Formula 1 racing with its carbon/carbon rotors. For the street, however, carbon/ceramic rotors perform better in a low-temperature range and provide excellent stopping, even when the brakes are cold.

CCM is absurdly light, approximately 50-percent lighter than cast iron. This reduction in unsprung weight translates into better overall braking, acceleration, and cornering performance. CCM rotors will retain their strength at 2,000 degrees Fahrenheit, while cast-iron liquifies at just over 2,100 degrees Fahrenheit.

For performance-minded hobbyists, a slotted rotor may be all that's needed. With Wilwood's two-piece rotors, owners can opt to run a slotted and cross-drilled rotor on the street and easily install a slotted rotor for track duty.

For performance-minded hobbyists, a slotted rotor may be all that's needed. With Wilwood's two-piece rotors, owners can opt to run a slotted and cross-drilled rotor on the street and easily install a slotted rotor for track duty.

The starting price point for a single CCM rotor can be as high as a complete big-brake system that uses more traditional two-piece cast-iron rotors. This is for two reasons. The exotic materials used in a CCM rotor take considerably longer to form; in addition, they are a "life-of-the-car" item that shouldn't have to be replaced.

Now that we've shown you why exotic materials are used in disc-brake designs, consider the main limitations on rotor size-budget and intended use. The bigger you go, the more expensive it's going to be, and don't forget the different wheels (and maybe tires) you will have to use. Just running a 14-inch rotor on a '02 Trans Am WS6 will require an 18-inch wheel in most cases. Keep these determinants in mind before selecting a rotor size.

Break-In

Rotors must be broken in properly. This procedure is called burnishing or bedding in.

Brake rotors come in many different configurations and sizes.

Brake rotors come in many different configurations and sizes.

Before using a new rotor, all machining and preservative oils must be completely removed following the manufacturer's recommendations. Usually it involves washing the rotors with soap and water or using one of the proprietary "brake-clean" compounds. Then mount the rotor and check it for run out.

It should be bedded in with a number of moderate/heavy stops, followed by a lot of cooling time between stops, gradually increasing the severity of the stops until the entire surface of the rotor is evenly discolored. This will prevent thermal shock, distortion, and the formation of "hot spots," regional deposits of pad material, which results in a permanent transformation of the cast iron underneath the deposit.

According to Brembo, once a rotor develops a hot spot, it must be replaced. Many automotive brake shops will "turn" or "cut" the rotor, but this is not a solution and it will only lead to the same problem.

Conclusion

Now that you're familiar with brake rotors and their different designs, you can make a fair judgment on which ones are right for your car. There are plenty of sizes, configurations, and materials to choose from, whether you want your Pontiac to perform better or just stand out.

In our next installment we will discuss brake pad friction materials, calipers, and fluids.

Cross-Drilled Versus Slotted

Once you've chosen the rotor design that is best for your application, it's time to add the bells and whistles, i.e., cross-drilling and slotting. The debate over which configuration is preferred has been going on for quite some time because there are stories of cross-drilled discs cracking, slotted discs eating up pads, and solid discs being the best overall.

These are cross-drilled ventilated discs...

These are cross-drilled ventilated discs...

What's true? We sat down with Brembo North America's chief engineer, Emanuele Bruletti, and High-Performance director, Adrian Smith, and asked them which disc design is the best.

HPP: There's been a lot of uncertainty surrounding cross-drilled and slotted rotors. People complain that cross-drilled rotors will crack under heavy use, yet some race cars still use them. I've heard that cross-drilling only benefits certain pad materials. How true is any of this?

Emanuele: Well, that is certainly a big question because not everyone agrees. From what we have found, yes, it is true that cross-drilling creates stress points for a crack to form, but that doesn't mean they're bad. Cross-drilling can help the rotor cool because it increases the surface area for the heat to dissipate.

It also wipes the pad surface clean, which helps with initial bite. Racers all want a confident brake system-something that bites right when they hit the pedal every time. Cross-drilling helps with this, and racers view rotors as disposable items and usually replace them after every race. So if cracks do form, they aren't on the rotor long enough to degrade the rotor's quality.

Adrian: That's why most racers just run a slotted rotor. A slotted rotor wipes the pad surface clean in the same way, so you get that instant bite that drivers are looking for without the enhanced risk of cracking. Cross-drilling is mainly a cosmetic feature because it has long been associated with performance brakes, but most racers have moved away from it.

...and pictured here are slotted ventilated rotors.

...and pictured here are slotted ventilated rotors.

HPP: So is it true that cross-drilling can cause the rotor to crack?

Emanuele: It certainly enhances the sensitivity for cracks to form, but if the rotor was designed to have cross-drilling, they can prove to be very strong and resilient. The owners should enjoy only the good attributes that go along with cross-drilling. Many of the cheaper bargain cross-drilled rotors are to be avoided.

HPP: Should someone looking for performance choose slotted rotors over cross-drilled?

Emanuele: It's a personal choice, but yes, I would say so. OEMs still use cross-drilled rotors on Ferrari, Corvette, and Porsche without the configuration becoming a major problem. Still, it's not as prevalent as one would assume, especially in street use. You will find that most race teams and hardcore track guys run only slotted rotors; only a few use a cross-drilled rotor.

HPP: What about "drilled and slotted" rotors? They have become more common for aftermarket add-ons.

Adrian: We only offer cross-drilled or slotted, but not both together. It's a bit redundant. The cosmetic value is rather high though.

After talking with Emanuele and Adrian, I was able to determine that while the rumors may have some truth to them, it comes down to personal preference and the intended use. However, cheap off-brand rotors should be avoided all together.