There’s no official metric that keeps track of this sort of thing, but it’s quite possible that the LS-series small-block has risen to global domination faster than any platform in the history of engines. With that insanely rapid growth rate of engine swaps and high-performance builds comes an equally mind-boggling rate of parts development. Twenty years ago, LS1s didn’t exist. Today, LS small-blocks have achieved a level of aftermarket support that rivals the Gen I small-block even though the hallowed Mouse got a 40-year head start. Not surprisingly, the ported, factory LS7 cylinder heads we bolted to our ’95 Camaro project car (aka The Purp) back in 2010 still work great, but don’t sit as high up on the totem pole as they used to. Seduced by all the new mega-port LS castings that are now available, we had to have a set of RHS’ 307cc Pro Elite LS7 heads. We figure that with our Camaro already running deep-10-second e.t.’s at the strip, the RHS heads could easily give it the bump it needs to push it into the single digits.

If the Camaro sitting before you looks familiar, it’s because it starred in a long series of build-up stories in GM High Tech Performance before getting adopted by Super Chevy. Built to compete in NMCA’s LSX Real Street class, it boasts a 720hp LSX small-block built by Late Model Engines, and features an impressive support cast of hardware that includes a Century Transmission Powerglide, a Chassisworks rollcage, a BMR Level 2 drag suspension, a Strange S60 rearend, an Aeromotive fuel system, and Strange brakes. During its very first run down the track, it laid down an impressive 10.23-second pass at 137 mph on 275mm-wide Mickey Thompson drag radials. Not too shabby, but we want more.

Back when The Purp’s 451 was built in 2010, the first aftermarket rectangle-port cylinder head castings started trickling into the marketplace. However, the 360 cfm dished out by GM’s factory LS7 heads was so good that they were deemed more-than-sufficient for our power goals. The talented crew at Late Model Engines improved upon them even more, hand-porting them to 399 cfm on the intake side and 256 cfm on the exhaust side at 0.700-inch lift. Since the plan back then called for driving to and from the track in a street legal package, we ordered up a custom 254/260-at-0.050 hydraulic roller camshaft with 0.646/0.630-inch lift to limit engine speed to a street-friendly 7,200 rpm.

As is often the case, projects like these inevitably drag out longer than expected, and in the meantime, the competition in Real Street has gotten much faster. To help us keep up with the pack, RHS set us up with a set of its CNC-ported Pro Elite LS7 castings. In addition to monster 307cc intake ports, they feature runners that have been raised 0.220-inch higher than stock. The straighter flow path from the port entry to the valve seat bodes well for airflow, and the RHS castings also have plenty of cross-section area to support a large-displacement combination like our 451. To take advantage of the additional airflow potential, we replaced the hydraulic roller cam with a custom Comp Cams 260/274-at-0.050 solid roller.

Although a big dose of nitrous was always part of the agenda, it never hurts to make as much power on the engine alone as possible. To find out just how much horsepower the cylinder head and camshaft swap is worth, our friends at the School of Automotive Machinists (SAM) stepped up to the plate once again. SAM has already performed the bulk of the final assembly on The Purp, including the installation of the safety equipment, interior, and fuel system as well as completing the wiring, dyno tuning, plumbing, and track tuning. Thanks to everyone at SAM for all their hard work. At the end of the day, the swap was very straightforward and proved to be well worth the effort.

The SAM Connection

If the LSX is a great engine platform, then building the fastest naturally aspirated LS-powered vehicle on Earth certainly earns some serious bragging rights. The people behind this impressive feat are the good folks at the School of Automotive Machinists, whose iconic orange ’99 Camaro SS has won five Chevrolet Performance Challenge Series All-Motor championships thanks to its ridiculous 8.0-at-170 mph e.t.’s. It passes the same knowledge it takes to build 1,100-horsepower, 9,600-rpm race engines on to its students through its industry-leading motorsports education program.

While many of its graduates go on to work for big-name shops like Hendrick Motorsports and Warren Johnson Enterprises, many start up their own shops. Bryan Neelen and Pecos Loughlin are two such graduates, who founded Late Model Engines in 2003. The LME crew was kind enough to build The Purp’s 720hp LSX back in 2010. As we learned the first time out at the track, LME knows how to build some seriously stout LS combos. Then in 2013, things came full circle, as we dropped our Camaro off at SAM for final assembly, and eventually, a new set of RHS heads.

01. Based on a Chevrolet Performance LSX block bored to 4.185 inches, The Purp’s 451 utilizes a Callies 4.100-inch forged crank, Compstar steel rods, and Wiseco 12.0:1 pistons. With a Mast single-plane intake manifold and a Wilson 4500 throttle body providing the air supply to hand-ported GM LS7 heads, the combo cranks out 720 hp on the engine dyno and 566 hp on the Dynojet.

02. Swapping out the heads and camshaft in a fourth-gen Camaro is never fun, but straightforward nonetheless. After removing the cooling fan, radiator, harmonic balancer, and water pump—then disconnecting the fuel lines, throttle-cable, injector harness, plug wires, steering shaft, and coolant hoses—it was time to dive into the belly of the best.

03. With the intake manifold, throttle body, rocker arms, valve covers, and headers removed, the cylinder heads slid right off the studs. Since The Purp prioritizes track performance over comfort, we deleted the power steering and A/C early on in the build to reduce weight and free up space under the hood. Along with the low-mount alternator, this definitely made the heads/cam swap a simper affair.

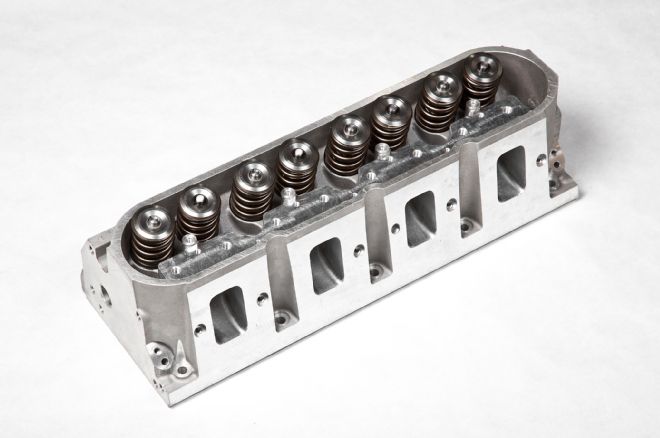

04. Although RHS does not publish flow bench numbers for its CNC-ported Pro Elite LS7 heads (PN 54504), the raised runners and increased port cross-section and volume definitely boost airflow potential. In a combo like ours that will eventually see a lot of nitrous, RHS’ beefy castings and 0.750-inch deck ensure positive head gasket seal.

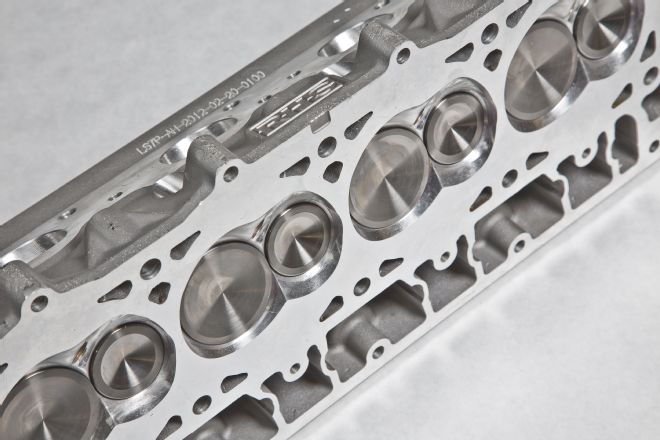

05. At 98 cc, the exhaust ports are quite a bit larger than stock as well. Likewise, the reinforced boltholes look like they mean business, and help reduce head distortion. Raised rocker rails also provide additional valvetrain clearance.

06. Since the new top-end package will see over 8,000 rpm, lightweight titanium valves are a must. They measure a big-block-sized 2.250/1.615 inches. The two additional boltholes at 12 o’clock and 6 o’clock allow increasing clamping load for superior cylinder seal. The combustion chambers check in at 69 cc and boast generous quench pads for enhanced detonation resistance.

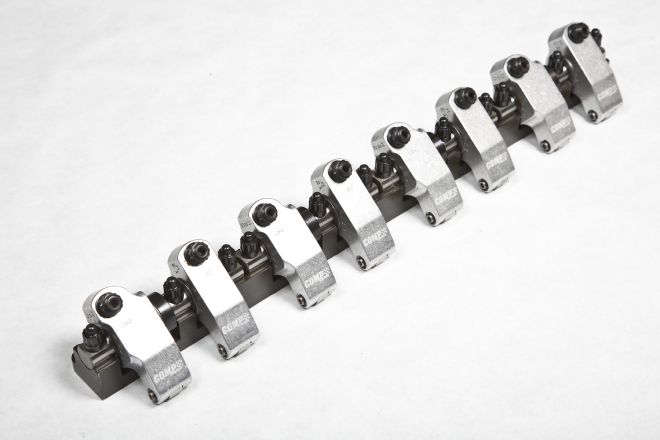

07. Designed specifically for the RHS Pro Elite LS7 cylinder heads, these Comp Cams shaft-mount 1.8:1 rockers utilize rugged 8620 hardened steel shafts for durability and 2024 aluminum rocker arms for reduced mass. At 8,000-plus rpm, a standard pedestal-mount rocker arm is marginal at best.

08. To optimize the valve events for the new RHS heads, SAM spec’d out a custom Comp Cams 260/274-at-0.050 solid roller featuring 0.757/0.757-inch lift. Its wide 114-degree LSA helps extend the powerband at high rpm. Although its duration figures aren’t that much more aggressive than the hydraulic roller it replaces, the solid roller employs steeper ramps for much quicker valve acceleration.

09. In any high-rpm solid roller cam application, the lifters must endure the tremendous load placed upon them by ultra stiff valvespring pressure. As such, Comp Cams set us up with its premium Elite Race lifters (PN 98956-16). They feature precision-ground 9310 steel wheels, EDM oiling holes, polished 8620 steel bodies, and micro-sorted needle bearings. The oversized 0.400-inch hollow axles are CNC-machined and dual-pinned.

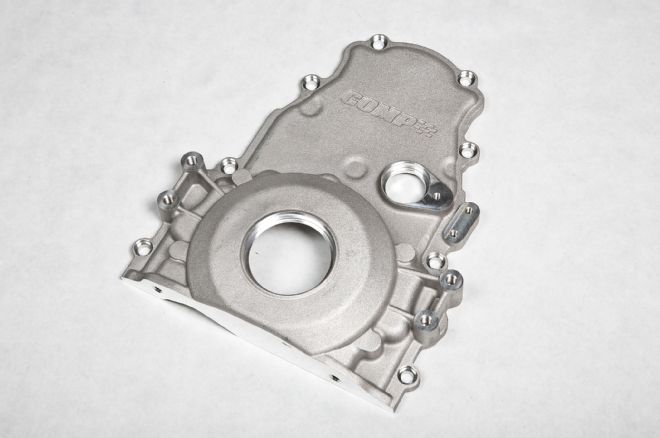

10. The stock LS timing cover is a very nice piece, but we were eager to try out Comp Cams slick new LSX cover (PN 5496). It provides plenty of clearance for double-roller timing sets and high-volume oil pumps. No grinding required. Other highlights include provisions for crank triggers and timing pointers.

11. After sliding the new camshaft into the block, the SAM crew dropped in the lifters. Unlike an OEM block, the Chevrolet Performance LSX block has windows cut into the lifter valley, which makes it much easier to position the lifters onto the cam lobes.

12. To ensure precise cam timing with the high-pressure springs, we opted for a Comp Cams billet double-roller timing set (PN 7102). In addition to allowing up to 8 degrees of adjustment, it comes pre-stretched and heat-treated.

13. Among the many great features of Cometic MLS head gaskets is that they are reusable. Since the 451 had just three track passes and a couple dozen dyno pulls on it, they still looked practically new, so we didn’t hesitate to reuse them.

14. With the new heads, rocker arms, and Manley pushrods bolted in place, SAM set the valve lash at 0.019 inch. Depending on maximum valve lift, SAM recommends setting the lash at 0.016-0.022 inch on solid roller cam applications.

15. After torqueing the ARP head studs to 80 ft-lb in three stages, the intake manifold and throttle body were reinstalled. Buttoning everything back up is the exact reverse of the removal process.

16. With the air/fuel dialed in to 12.7:1 and the total ignition set to 28 degrees, the new RHS heads and custom Comp solid roller cam helped lay down 602 hp and 509 lb-ft using VP100 on SAM’s Dynojet chassis dyno. That’s a solid increase of 36 hp over the ported factory LS7 heads. We can’t wait to bring home some 9-second timeslips.