There was a time when an engine builder’s arsenal of power-producing weaponry was much smaller than it is today. Before nitrous was as widely available (or as well understood) as it is today, while turbochargers were practically military-grade technology, and when blowers were exotic – read expensive – hardware, the average racers of the golden era of hot rods still found ways to go fast. So how did they do it? Three ways: cubic inches (courtesy of Detroit); big compression; and fuels such as alcohol, nitromethane, and some even nastier stuff than that.

That old-school mentality of power production is just as alive now as it was back then; only today, racers have a larger plethora of go-fast parts to choose from to meet their horsepower and e.t. goals without resorting to forced induction.

While Super Chevy usually focuses more on the pump gas, street/strip style of Bow Tie powerplants, we took a step off our usual path this issue to cover a more nostalgic, more radical style of engine build. The recipe was simple: big cubic inches, tons of compression, and good ol’ alky — mechanically injected, the way it was intended to be.

We jumped at the opportunity to watch project Old School, Bad come to life in the same style it might’ve 50 years ago, but paired with the cutting-edge parts racers of yore would’ve killed for.

The powerplant’s owner and builder, Ken Gilispie has been racing since 1984, and in that time, has been behind the wheel of just about everything short of a rocket ship — though rocket fuel is likely a different story.

Follow along as Ken assembles a 572-cubic inch engine for drag racing abuse in an ’80s Top Alcohol Funny Car chassis. With the engine’s expected quadruple digit output, and the car’s 1,400-pound curb weight, it is expected to lay down 7.20s in the quarter-mile without breaking a sweat.

Next month we will check back on the build as it goes full-song on the engine dyno at Westech Performance. Will it be able to crack the 1,000-horsepower mark on a naturally aspirated, 24-degree head? We can’t wait to find out. But for now, enjoy the subtle nuances of assembling a bad-to-the-bone, big-cube race engine and the awesome parts that make it possible.

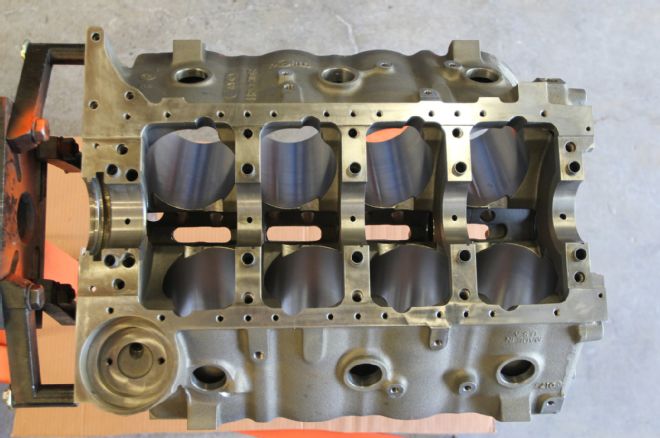

1. Being that a massive displacement and a stout cylinder block were paramount for our four-digit horsepower goal, a World Products Merlin III block formed the basis for the build. With a max bore size of 4.625 inches and a tall, 10.200-inch deck height, the block is capable of generating over 600 cubic inches. We ordered our block with a 4.495-inch bore that was finish honed to 4.500. Other benefits of the Merlin III block included priority main oiling and billet steel four-bolt splayed caps.

2. After the World block was finish-honed to size by Dougan’s Engine and Machine in Riverside, California, it was ready for assembly. Installation of this custom Bullet camshaft was the first step of the build. The bumpstick specs in at a serious 0.900-inches of lift on the intake and 0.850-inches of lift on the exhaust. Duration lasts 285 and 300 degrees respectively at 0.050-inches of lift, and the lobes are ground on a 115 lobe separation angle.

3. Gilispie sets the Crower 4.500-inch stroke Enduro forged crank into the block after checking clearances on the Clevite bearings. This monster of a crank weighs in at 85 pounds due to all of the extra strengthening material. Kerry Novak, of Crower, said this same raw forging is used to make both big-block Chevy cranks as well as nitro hemi cranks. That’s some serious strength.

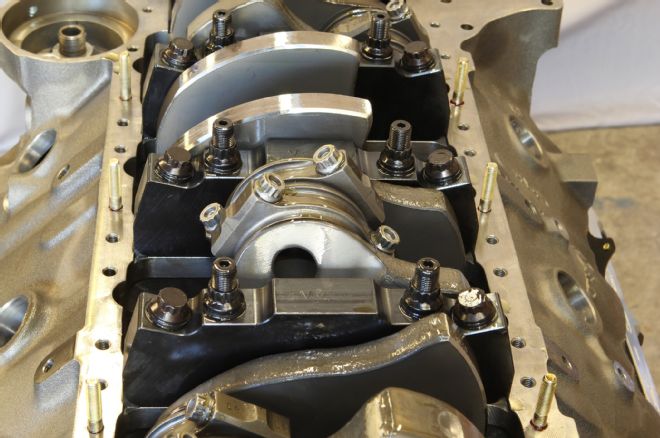

4. World Products takes no chances with the bottom end of their Merlin III block. These four-bolt billet steel splayed caps rigidly anchor the crank into the block’s beefed-up webbing and ensure high-horsepower outputs don’t cause the ever-dreaded cap walk.

5. Gilispie torques the ARP 12-point hardware in the main caps in three stages, just like any other bottom end.

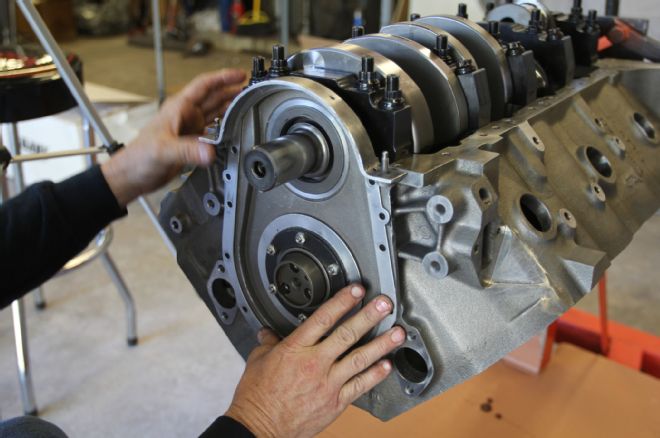

6. A beltdrive is the preferred method of camshaft phasing and adjustment. “It offers lighter weight and easier adjustability than a timing chain,” said Gilispie. He installed the thrust plate and cover then uses a dial indicator to check endplay. Because the engine uses a solid roller camshaft, excess endplay is a major concern. If the cam moves too far fore or aft, it will toast a roller lifter. The beltdrive also has a small pulley to drive the front-mount distributor.

7. These forged 2618 aluminum pistons are the careful machine work of Ross Racing Pistons. In order to deliver a whopping 16.2:1 compression, gigantic domes mirror the chambers in the Profiler Sniper X heads. They utilize a modern thin ring pack and are drilled for gas ports to seal the fire and flames. Total Seal gapless piston rings are also utilized to contain the massive compression.

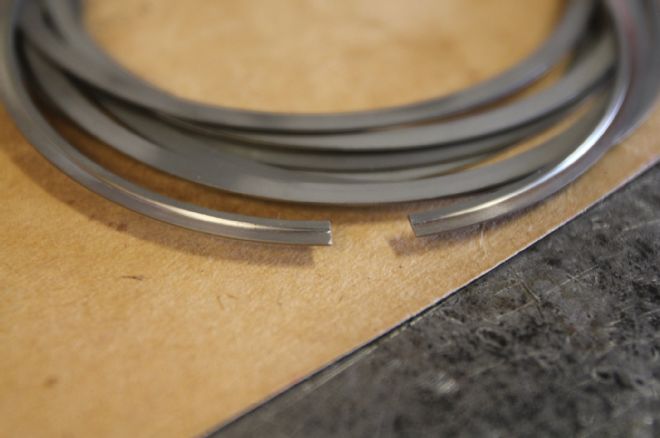

8. Here is a close-up showing the Total Seal gapless piston rings. The lower ring has a very small L-shape cut into it. This allows an upper ring to seat on top of it and the gaps between those two rings are spaced 180 degrees apart. The rings increase cylinder pressure and, especially in alcohol applications, help prevent fuel from washing down the bores and contaminating the oil.

9. Gilispie hangs the rings on the Ross Pistons, using a spiraling motion for the oil rings and ring expanding pliers for the compression rings. It’s important to install all rings properly, but thin rings even more so. If you put a bend into them, say goodbye to a good cylinder seal.

10. MLS head gaskets from Cometic seal the combustion chambers, while ARP cylinder studs provide the clamping load on the Profiler cylinder head.

11. With the bottom end complete, the Profiler 375cc Sniper X CNC heads are lowered over the studs and onto the Merlin III’s deck surface. In case you were wondering; yes, you can drop an iPhone down the intake port. Ask us how we know. These heads flow an insane 477 cfm at 0.900-inches of lift on the intake port – That’s flow the massive cam can take full advantage of.

12. Connecting the Ross Racing Pistons to the crankshaft are a set of Crower Maxi-Light rods. This is a serious set of billet steel rods that is more than ready to handle the downright mean horsepower this engine will throw at them.

13. This custom aluminum oil pan will seal the bottom end and carry the lifeblood of the engine, while a Fel-Pro one-piece rubber gasket will keep everything leak free. When using long-stroke cranks such as this Crower 4.500-inch unit, care needs to be taken when selecting an oil pan. This pan has the sides pushed out to the maximum to clear the rods and counterweights. Note the pipe plugs that are removed to gain access to the inner pan bolts.

14. With the kind of spring pressure required by the 0.900-lift Bullet cam (375 pounds on the seat and over 1,000 pounds at full lift), a stout valvetrain is a requirement, not a suggestion. Erson solid roller lifters with bronze-bushed wheels transmit power to Manton 7/16-inch pushrods and T&D shaft-mount rockers – a parts grouping favoring strength and valvetrain stability above all else.

15. A feeler gauge is used to set the cold lash between the T&D rocker and the Erson triple springs, retainers, and valves.

16. Gilispie polished the lifter valley to aid in return oil flow to the pan, something he has done on all of his race engines. The Merlin III block can also be ordered with bronze bushed lifter bores, though this block does not have that option.

17. Massive Fel-Pro race gaskets seal the intake manifold to the head, along with a healthy dose of grey silicone.

18. With the valvetrain buttoned up, Gilispie lowers a massive, Dart tunnel-ram onto the engine. The intake is available with multiple tops for single carb, dual carbs, and various kinds of injection systems. It is also cast with plenty of bosses for fuel injectors or nitrous nozzles to call home.

19. The manifold comes with ports designed for more modest cylinder heads, but there is tons of meat for port matching. Gilispie spent just under a day hogging out the intake to mate up to the giant 375cc runners on the Profiler Sniper X CNC heads.

20. Here’s a close-up of the injector nozzles for the Enderle system.

21. This Enderle Injection set was originally plumbed for a low-deck block, so it took some adjustment of the injector lines to get everything plumbed properly for the 10.200-inch deck height of the Merlin III block. The lines all stem from the barrel valve and distribution block, which supplies idle and wide-open-throttle mixture to the engine.

22. This aluminum adapter allows the Enderle Injection to bolt to the top of the Dart tunnel ram intake manifold.

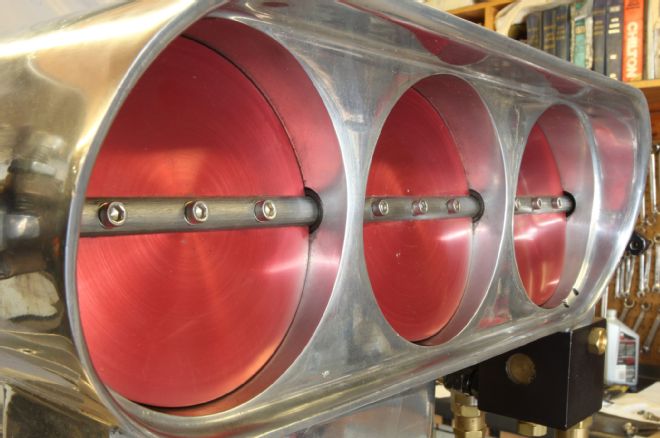

23. Lastly, the massive Bird Catcher injection bolts to the adapter plate.

24. The Mallory front-mount distributor runs off the beltdrive rather than the camshaft, which provides a more accurate timing signal by eliminating any flex of the cam from the equation.

25. If this isn’t a menacing induction system, nothing is. The completed 572ci engine is now ready to tear it up on the dyno. Stay tuned!