Today's high-tech V-8 engines are truly amazing. By incorporating advanced engineering, the latest production methods, lightweight materials, and a full compliment of electronic controls they produce incredible amounts of power, are surprisingly efficient and durable. Of course the same attributes can also be found in most contemporary microwave ovens.

While the new crop of engines from the OEMs are impressive from a technological standpoint there are those among us (Brennan being a notable exception) who appreciate simplicity—internal combustion in its basic form. And when it comes to being simple and basic nothing can match the Ford Flathead V-8—it's the toaster oven of engines.

When the Flathead V-8 was introduced in 1932, it had a displacement of 221 ci and was rated at 65 hp. Over the years Ford refined the Flathead. A big improvement in driveability came about in 1934 when the Detroit Lubricator single-barrel carburetor was replaced by the Stromberg two-barrel and a redesigned intake manifold. Those changes resulted in 85 hp.

For 1936 insert main bearings first appeared, however Ford used up the supply of babbit bearing blocks before installing the improved version. In 1937 a number of significant improvements were made internally and the water pumps were moved from the heads to the front of the block and the redesigned heads had centered coolant outlets. This was also the year that the Stromberg 97 replaced the Stromberg 48, then late that year the Chandler-Grove carburetor appeared (it would later become the Holley 94).

For the first part of 1938 the only change in the V-8 was the size of the spark plugs. Late in the year the 24-stud engine appeared, which referred to the number of head fasteners on each bank (previously 21 studs that had been used). Big changes came in 1939 with the introduction of the Mercury. Ford versions of the Flathead retained the familiar 3-1/16 inch bore and 3-3/4-inch stroke for 221 ci. The Mercury used the same crank, but by virtue of a larger 3-3/16 bore, it displaced 239 ci.

With the exception of a compression ratio increase that bumped the Ford's horsepower to 90 and the Merc to 100, nothing significant changed until 1946. In an effort to prevent the block from cracking the valves were moved up from 52 degrees from vertical on the left side and 49.5 degrees on the right, or an included angle of 101.5 degrees and were now 100 degrees apart. These postwar blocks can be identified by raised letters on the bellhousing, 59, 59A, 59L, 59,X, 59Y, or 59Z.

Significant changes were made to the Flathead in 1949. The block was redesigned, there were changes to the water jacket holes in decks, and the outlets (with removable thermostat housings) were moved to the front of the heads for improved cooling. Cap screws were now used instead of studs to retain the heads, although there were still 24 per side and the pattern was the same. Up front a new distributor was added while the rear integral bellhousing was deleted. Another significant change was the 4-inch stroke crank used in the Merc (referred to as the 8CM) that upped the displacement to 255 inches for 112 hp, while Ford (the 8BA) had a 3-3/4-inch stroke and remained at 239 ci and 100 horses.

Almost from its introduction Ford Flatheads were modified for increased performance and one of the common alterations was to add more carburetion. As the speed equipment industry grew manifolds for two, three, and even four carburetors (about as many as the space available allowed) became available. Another induction option for Flatheads, although not as common, was supercharging. Given the asthmatic breathing conditions these engines suffer from putting them under pressure is a sure cure.

In this day of readily available, affordable, high-performance powerplants the obvious question is "does it make any sense to build a Flathead, and why would anyone do it?" The answer is simple and has nothing to do with what makes sense. The reasons for building a Flathead are the appreciation of tradition, their unique look and sound. Buying horsepower is easy, coaxing it out of an engine design that dates back more than 80 years while knowing at best it will be less than a modern baseline crate motor requires passion—and you either have that or you don't.

One place where passion for these engines remains alive and well is H&H Flatheads. A family business, H&H is headed up by Mike Herman on the V-8s, Max Herman III on the four-bangers, and Max Herman Jr. runs the R&D department.

After the doors opened in 1972 H&H quickly gained a reputation for quality and they have grown and expanded their services to include other vintage engines. In addition they are now the exclusive distributors of Navarro Racing Equipment, Sharp Speed Equipment, and offer a line of products including Navarro air cleaners, Navarro 471 Blower Kits, V-8/60 adjustable lifters, and the all-new S.Co.T. blower kits.

Thanks to Mike Herman we were able to gather photos of the most popular intake options H&H currently offers for early (1932 to 1948) and late (1949 to 1953) Flatheads. While the manifolds look similar there are significant differences. The positions of the carburetors on two-two manifolds vary and as a result some require moving the generator, others don't (manifolds that accommodate the generator are often called regular dual, while those with the carbs further apart are usually referred as super dual). By spreading the carburetors further apart they have a straighter shot into the ports and fuel distribution is improved but relocating the generator requires a head-mounted bracket. Some manifolds are equipped with exhaust heat, others aren't. In cool locales with today's fuel exhaust heat can help driveability, in hot climates it's not normally necessary. All the manifolds shown here accept the stock-style fuel pump stand and the oil filler/road draft tube for 1949 to 1953 applications. Another difference is the number of bolts used to secure the manifold. Due to the shape of the runners, in some cases, the number of bolts has been reduced. On the other hand, in some cases, there are more holes in the manifold in the block, but in either case it’s not a problem.

Although all the manifolds shown are good, some manifolds may perform better than others with a given engine combination. The best bet to resolve that issue is to deal with an expert on the subject like Mike Herman. But first, check out the following photos for options on fueling your passion.

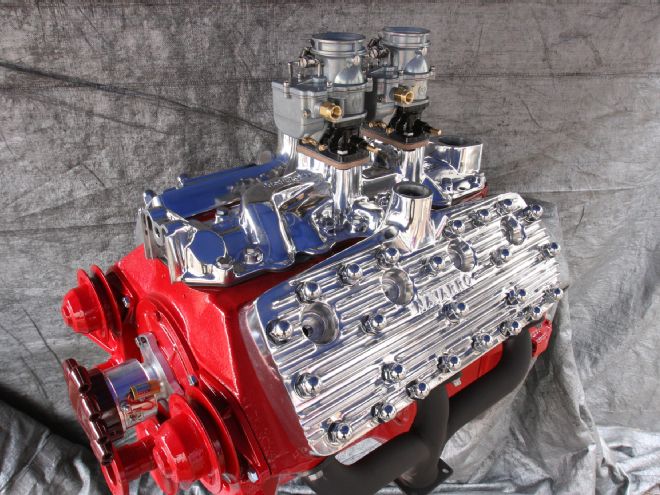

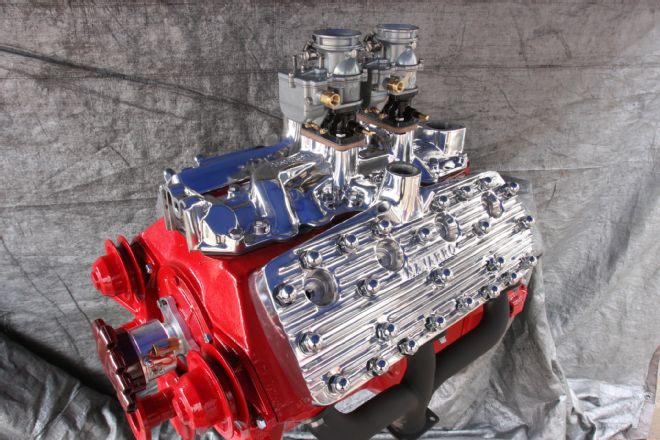

This 24-stud Flathead is equipped with Navarro heads and intake. This standard dual mounts a pair of Stromberg 97 carburetors and it has exhaust heat.

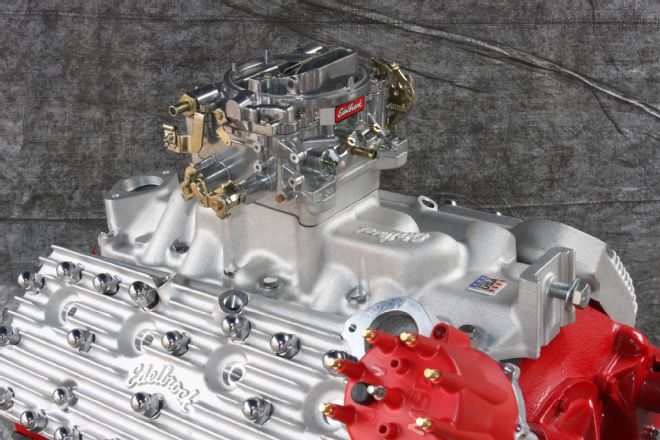

The Edelbrock Slingshot manifold is a reproduction of the original designed by Vic Edelbrock Sr. in 1938. Shown here with Edelbrock Vintage 94 carburetors, the manifold has exhaust heat and the generator mounts in the stock location.

Offenhauser offers this regular dual for 8BA and 8CM Flatheads. Like most regular dual manifolds it is exhaust heated.

The Edelbrock Super Dual eliminates the heat crossover and was designed for Ford and Mercury engines from 1938 to 1948. Also shown is the head-mounted generator bracket.

Here is a polished Navarro regular dual with exhaust heat on an early block. Note the boss next to the generator mount for the oil filler/draft tube on 1949-53 applications.

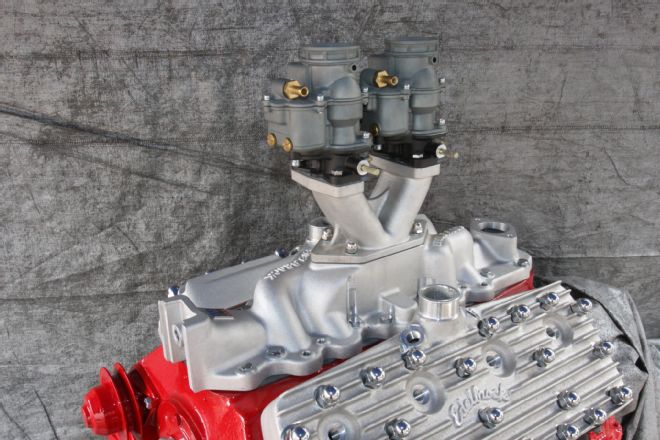

Navarro's exhaust heated regular dual for 8BA/8CM applications. Compare the heights of the runners and the position of the carburetors between the various regular manifolds.

Offenhauser's regular dual for early blocks has noticeably different runners compared to the Navarro.

This polished Sharp regular dual for early engines is not equipped with exhaust heat and the generator mounts in the stock location.

An example of a regular dual without exhaust heat is this Sharp for 8BA/8CM Flatheads.

Note the position of the carburetors on Offenhauser's 8BA/8CM-style super dual intake. This manifold does have exhaust heat and requires the generator to be offset.

Called the universal dual, this early style Navarro manifold is heated and requires the generator to be relocated.

Referred to as the racing dual, this early style Navarro manifold has the heat riser passages blocked.

The Navarro racing dual is also available for 8BA/8CM applications.

Another version of the exhaust-heated Navarro universal dual, this example is for late engines.

It's easy to see on this polished early style Sharp manifold that spreading the carburetors apart gives them a straighter shot at the ports.

This is a non-heated, super-dual Sharp manifold for a late-style engine.

Offenhauser offers this three-two manifold for early engines. It has exhaust heat and no provision for a generator mount.

By comparison, this early style Sharp three-two manifold lacks exhaust heat and does have a generator-style mount (normally used to attach an idler for the V-belt).

Notice the difference in the runner shapes between this early style Navarro three-two manifold and the Sharp.

Another Navarro three-two manifold, this example can be used on early or late engines.

This Edelbrock 8BA/8CM triple manifold mounts a trio of Edelbrock Vintage 94 carburetors.

Another three-two manifold from Sharp, this example is for late engines and does not have exhaust heat.

Most Flathead four-barrel manifolds, like this Offenhauser, are drilled for a Carter WCFB carburetor. H&H recommends the use of adapter to mount a Holley 390-cfm vacuum secondary carburetor.

Edelbrock offers a single four-barrel manifold with an adapter to allow the use of square-bore carbs, such as the Edelbrock Performer Series or Thunder Series AVS 500 cfm.

Navarro's single four-barrel manifold was said to be his best flowing design. It can be used on early and late engines.

For serious performance, H&H offers Navarro manifolds that mount a 4.71 GMC blower. Note the pop-off valves on each side.

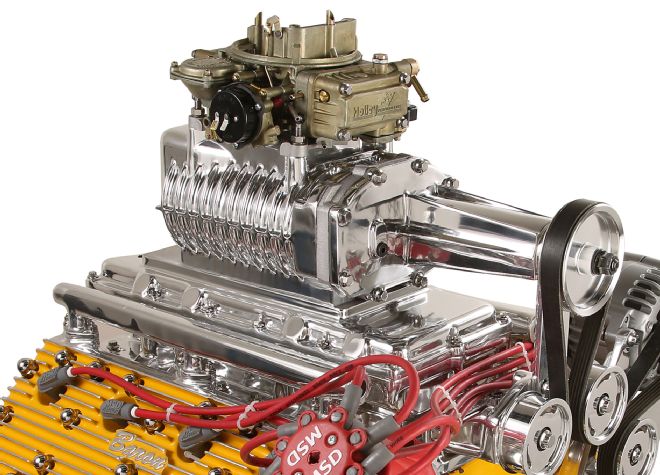

This impressive package is the all-new version of the vintage S.Co.T. blower kit available exclusively from H&H.

One of the best-known names in supercharging is Magnuson. This is their 1949-53 kit that uses a hybrid GMC blower with Eaton internals.

TorqStorm's Vintage Series centrifugal supercharger is for '49-53 Flatheads. It includes a carb hat for dual carbs or a single four-barrel.

With the introduction of new Stromberg 97 carburetors it's no longer necessary to try and resurrect worn-out originals; H&H can supply them.

Stromberg now offers a larger version of the 97. Completely reworked internally, they flow 250 cfm, compared to the original's 165 cfm.

To prevent fuel from percolating in the float bowl Stromberg offers these gasket and 1/4-inch phenolic insulator kits.

Speedway Motors offers their version of a vintage carburetor, it's called the 9Super7. It has the same bolt pattern as the Stromberg 97.